Dual Metallising Ltd

Established in 1982, we are a family-run business who produces plastic metallising moulding reflectors. Our teams of highly experienced workers can provide plastic metallising moulding reflectors with a variety of finishes and can work on single items or full production quantities.

We have nurtured a reputation based upon efficiency and reliability and have a loyal customer base who returns to us because of our fast and expansive services.

Filter products and services

-

Make and design Point of Sale (PoS) and Display

Here at Dual Metallising, we specialise in vacuum metallising, plastic injection moulding and spray painting. We offer Make and design Point of Sale (PoS) and DisplayRequest a Quote Supplied by Dual Metallising Ltd -

Matt Plating

Here at Dual Metallising, we specialise in vacuum metallising, plastic injection moulding and spray painting. We offer Matt PlatingRequest a Quote Supplied by Dual Metallising Ltd -

Metalising

Here at Dual Metallising, we specialise in vacuum metallising, plastic injection moulding and spray painting. We offer MetallisingRequest a Quote Supplied by Dual Metallising Ltd -

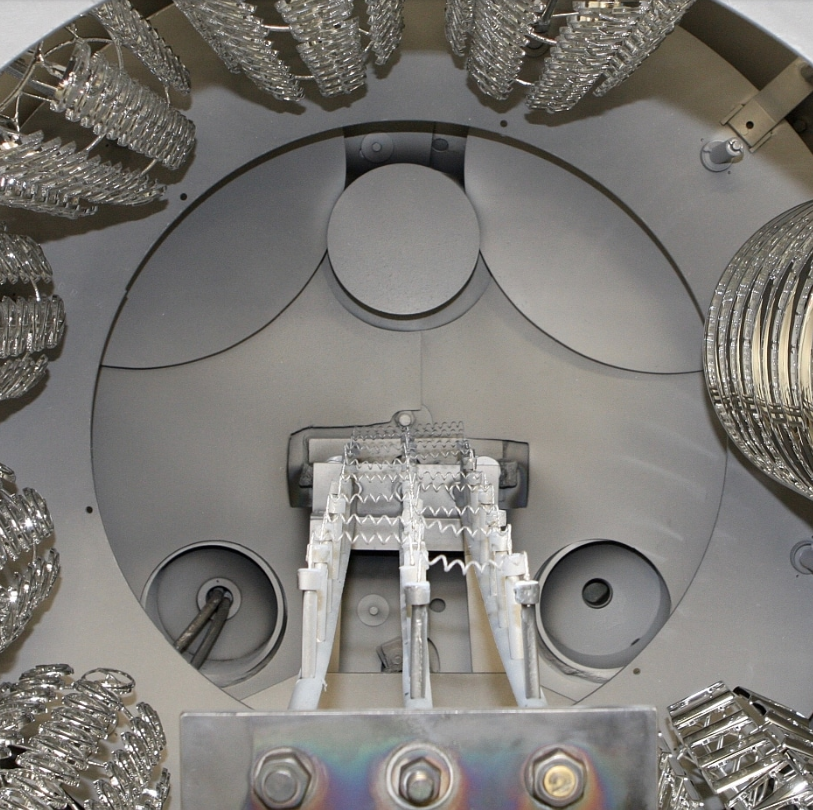

Metalising Moulding Reflectors

Dual offer both moulding and vacuum deposition, a complete process for finishing reflectors in most polymers.Request a Quote Supplied by Dual Metallising Ltd -

Metallised finishes

Here at Dual Metallising, we specialise in vacuum metallising, plastic injection moulding and spray painting. We offer Metallised finishesRequest a Quote Supplied by Dual Metallising Ltd -

Metallising to Glass Substrates

Dual Metallising can plate many shapes, sizes and types of glass from a candleholder or tumbler to globes often used in lighting. Many glass items will need a special production jig to keep them steady during the process, due to the fragile nature of the parts. Dual can run both large and small quantities of glass items in addition to multiple substrates including metal and plastic.Request a Quote Supplied by Dual Metallising Ltd -

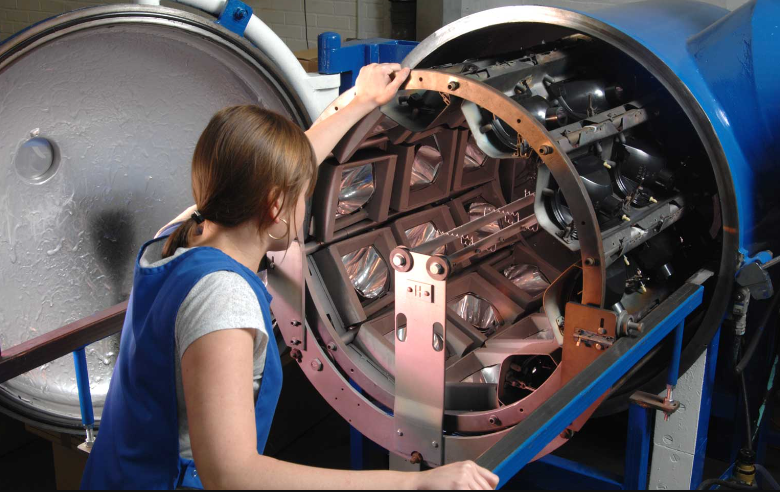

Moulders, Mouldings Injection, Plastics

We have continuously invested in our moulding equipment and processes, this has resulted in Dual Metallising being able to offer a highly consistent service. Our state of the art machinery and tools enable us to efficiently manufacture, mould and finish products to customer specification. We have cutting-edge six microprocessor controlled machines that offer a clamping capacity ranging from 60-250 tonnes and shot weights of up to 800 grams in most polymers.Request a Quote Supplied by Dual Metallising Ltd -

Moulding and vacuum deposition

Here at Dual Metallising, we specialise in vacuum metallising, plastic injection moulding and spray painting. We offer Moulding and vacuum depositionRequest a Quote Supplied by Dual Metallising Ltd -

Nylon Components

Here at Dual Metallising, we specialise in vacuum metallising, plastic injection moulding and spray painting. We offer Nylon ComponentsRequest a Quote Supplied by Dual Metallising Ltd -

Onto Plastic Plating

Here at Dual Metallising, we specialise in vacuum metallising, plastic injection moulding and spray painting. We offer Onto Plastic PlatingRequest a Quote Supplied by Dual Metallising Ltd