Eatec Ltd

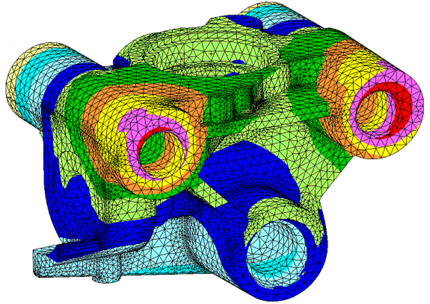

Where complex structures or loadings are involved, a stress analysis using FEA (finite element analysis) provides a level of accuracy which cannot be achieved through hand calculations. Eatec specialises in stress analysis using FEA, and has been assisting clients in a range of industries for over 30 years.