Industry Showcase: Cryogenics

16 August 2023It’s time for another instalment of the Industry Showcase. These blogs aim to delve deeper into the industries that EWFM products cater to. Previously, we have explored key information about the oil & gas, food & drink, and chemical industries, and highlighted the suitability of EWFM products for these sectors. In this month’s edition of the showcase, we will focus on the cryogenic industry. Industry forecasters predict significant growth for the cryogenic industry in the future, estimating its value to reach around £35 billion by 2030. But what is driving this increased demand for cryogenics?

About the Cryogenic Industry:

The cryogenic industry encompasses a wide range of sectors involved in the production, distribution, and application of technologies and products designed to operate at extremely low temperatures. It plays a vital role in various fields, including industrial gases, energy, healthcare, research and development, aerospace, defence, and more.

The recent increase in demand for cryogenic practices can be attributed to the climate change situation. Natural gases are often considered the future of clean energy as they are seen as a more environmentally friendly alternative to fossil fuels. They burn cleaner compared to fossil fuels, which are predominantly used at present.

To convert cryogenic materials into energy, a typical process involves a cryogenic energy facility. In this facility, cryogenic materials such as air are stored and chilled, causing them to transform into their liquid form. When the liquid air warms up, it expands, and this expansion is harnessed by a turbine, which then generates electricity.

The term given to natural gases cooled down in the cryogenic process is Liquefied Natural Gas (LNG). These gases can reach temperatures as low as -162°C, requiring the use of well-engineered products to ensure safe production and protect employees working with the materials.

What EWFM can do for Cryogenic related practices:

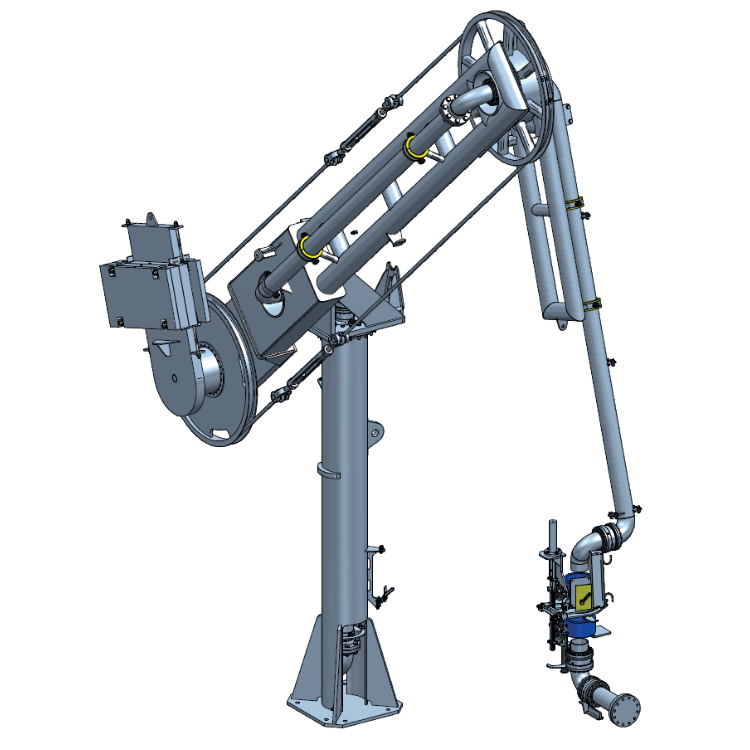

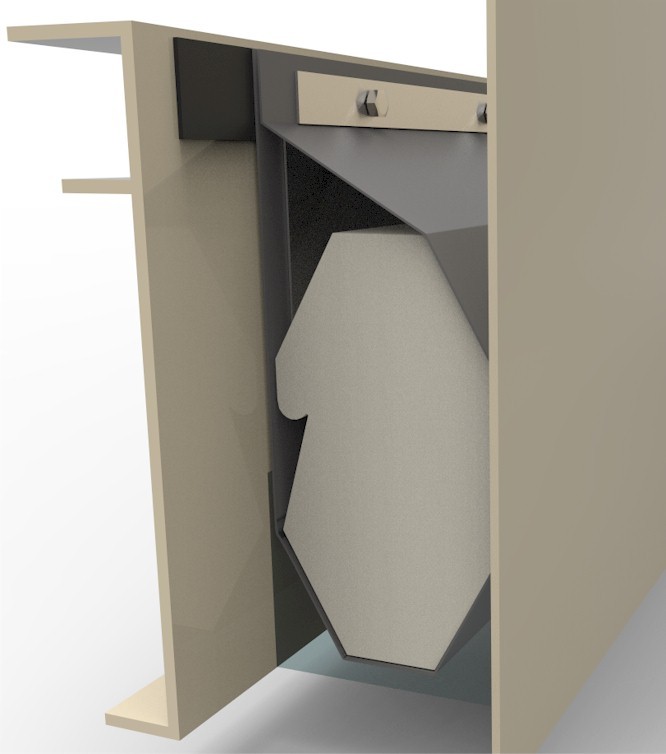

That’s where EWFM comes in. We offer a range of products specifically suited for cryogenic applications, including Swivel Joints, Couplings, and Breakaway Couplings.

Our Swivel Joints are available with a Nitrogen Purge feature, which surrounds the ball bearing raceways with nitrogen to prevent freezing and ensure smooth operation even in extremely cold conditions. Additionally, they are equipped with UHMW-PE seals that are specially designed for cryogenic applications. Our cryogenic swivels have undergone testing under third-party inspection, establishing their reliability and performance.

For cryogenic coupling needs, our Manntek Cryogenic Couplings and Breakaway Couplings are designed to operate at temperatures as low as -163°C and -196°C. These products comply with ISO 18683 and the new ISO 21593 standards. ISO 18683 focuses on the safety and risk assessment of LNG fuel bunkering operations, while ISO 21593 outlines the technical requirements for dry-disconnect/connect couplings for bunkering liquefied natural gas.

If you work in the cryogenic industry and are seeking products to enhance your company’s production processes, we encourage you to get in touch with EWFM. Our team is readily available to provide expertise and tailored solutions for your specific projects.