Fleming Polymer Ltd

Fleming Polymer Testing & Consultancy is an independent test-house offering the outsourcing of specialised analytical polymer testing facilities to the polymer industry. The business is dedicated to solving polymer problems through sophisticated testing, high level consultancy and process simulation. Our customers, most of whom are household names, are of course the cornerstone of the business, and to this end we appreciate the need to provide rapid solutions.

We deliver value added benefits, which serve both to protect and increase profitability and operate to ISO 9001:2008. The company has been operating for over 15 years, has won a DTI Smart award and been granted a patent for rheometry design.

The company has worked with industry leaders such as; GlaxoSmithKline, BD, Exxon, Uponor, Malvern Instruments, Tyco, TIAutomotive, NPL, Moldflow and Victrex to name but a few. Test Specialisms include;

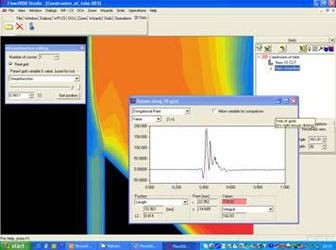

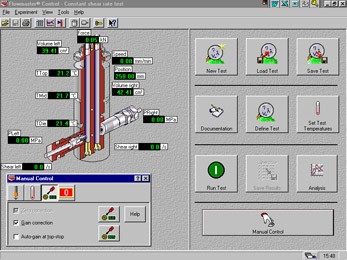

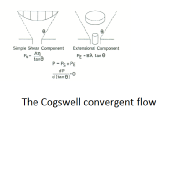

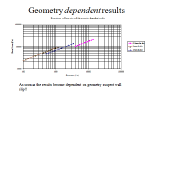

- Capillary Rheometry

- FTIR

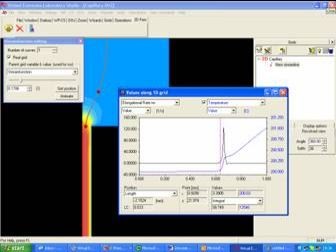

- Extrusion Flow Simulation

- MFR/MVR

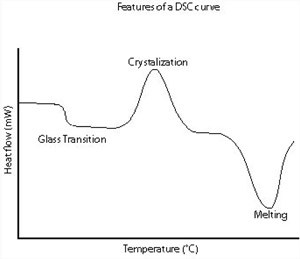

- DSC

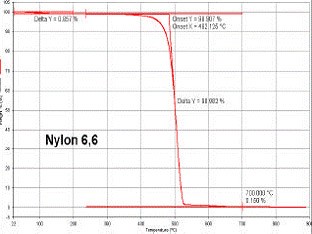

- TGA

- Instrumented Impact

- Elongational Viscosity

- Compuplast VEL distributor

Filter products and services

-

Impact Testing

Impact testing today constitutes an important end product and fit for purpose test. Following manufacture many products will experience some form of service impact specific to their environment, it is the aim of the impact tester to replicate these service impacts in order to assess their fitness for purpose.Request a Quote Supplied by Fleming Polymer Ltd -

Instrumented impact testing

Instrumented impact testing today constitutes and important end product and fit for purpose test. Following manufacture many products will experience some form of service impact specific to their environment, it is the aim of the impact tester to replicate these service impacts in order to assess their fitness for purpose. Instrumented impact, as opposed to pendulum impact, generates the entire force vs time fingerprint and provides a more thorough insight into the particular failure mode.Request a Quote Supplied by Fleming Polymer Ltd -

Instrumented Impact Testing

Impact testing today constitutes an important end product and fit for purpose test. Following manufacture many products will experience some form of service impact specific to their environment, it is the aim of the impact tester to replicate these service impacts in order to assess their fitness for purpose. The system can be used for:

- Polymers

- Polymer composites

- Metals

- Ceramics

Our Rosand IFW413 instrumented falling weight impact tester has features including:

- Tower Height: 1.3m

- Maximum available impact velocity: 5m/s

- Energy Range: 0.05 to 200J

- Force range: 10 to 50,000N

- Data acquisition: 12bit resolution, 670ksamples/s, 4000 data points

- Temperature controlled environment

For more information, please see our video.

Request a Quote Supplied by Fleming Polymer Ltd -

Measurement of Viscosity

Measurement of ViscosityRequest a Quote Supplied by Fleming Polymer Ltd -

Melt Mass Flow Rate (MFR)

At Fleming Polymer Testing and Consultancy, we specialise in melt mass-flow rate (MFR) which can be used either as a one number indicator of polymer viscosity in the melt phase and/or a QA test. Melt mass flow rate features include:- Indicative of weight average molecular weight

- Indicative of melt viscosity

- An easy to use 1 number quality test

- ability to measure melt density

- Essentially a simple capillary rheometer

- testing to ISO1133-1:2011

Request a Quote Supplied by Fleming Polymer Ltd -

Melt Volume Flow Rate (MVR)

Melt mass flow rate, or MFR (or indeed melt flow index as it is sometimes referred to), is a one number value which indicates the viscosity of a polymer in the melt phase. The higher the number, the lower the viscosity and correspondingly, the lower the umber the higher the viscosity. The viscosity, or resistance to flow, is also indicative of the weight average molecular weight of a polymer and so this one number gives a rapid indication of two very important variables. This simple test is also widely used as a QC test and many companies accept or reject incoming polymer by comparing the value they measure with that on their certificate of conformity. The test is standardised in ISO1133-1:2011 which stipulates a range of temperature and mass combinations for suggested resins.Request a Quote Supplied by Fleming Polymer Ltd -

Melt Volume Flow Rate (MVR)

At Fleming Polymer Testing and Consultancy, we specialise in melt volume-flow rate (MVR) which can be used either as a one number indicator of polymer viscosity in the melt phase and/or a QA test. Melt mass flow rate features include:- Indicative of weight average molecular weight

- Indicative of melt viscosity

- An easy to use 1 number quality test

- ability to measure melt density

Request a Quote Supplied by Fleming Polymer Ltd -

MFI

The Melt Mass-Flow Rate is a one number indication of the viscosity of a polymer in the melt phase. It is defined as the mass of polymer in grams flowing per 10 minutes through a capillary of specific diameter and length by a pressure applied via a range of standard weights at specified temperature.Request a Quote Supplied by Fleming Polymer Ltd -

MVR

The Melt Mass-Flow Rate is a one number indication of the viscosity of a polymer in the melt phase. It is defined as the mass of polymer in grams flowing per 10 minutes through a capillary of specific diameter and length by a pressure applied via a range of standard weights at specified temperature.Request a Quote Supplied by Fleming Polymer Ltd -

Pilot blown film line

A lab- scale blown film line is available for the pilot production of developmental mono-layer film formulation and trials. In many cases the extruder can be used beforehand to create a blend which can then be extruded again using the film line. In this way a series of formulations can be examined for process optimisation and service properties on a small scale rather than the costlier alternative of using a production-scale line.Request a Quote Supplied by Fleming Polymer Ltd