Fleming Polymer Ltd

Fleming Polymer Testing & Consultancy is an independent test-house offering the outsourcing of specialised analytical polymer testing facilities to the polymer industry. The business is dedicated to solving polymer problems through sophisticated testing, high level consultancy and process simulation. Our customers, most of whom are household names, are of course the cornerstone of the business, and to this end we appreciate the need to provide rapid solutions.

We deliver value added benefits, which serve both to protect and increase profitability and operate to ISO 9001:2008. The company has been operating for over 15 years, has won a DTI Smart award and been granted a patent for rheometry design.

The company has worked with industry leaders such as; GlaxoSmithKline, BD, Exxon, Uponor, Malvern Instruments, Tyco, TIAutomotive, NPL, Moldflow and Victrex to name but a few. Test Specialisms include;

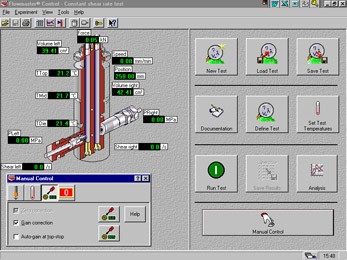

- Capillary Rheometry

- FTIR

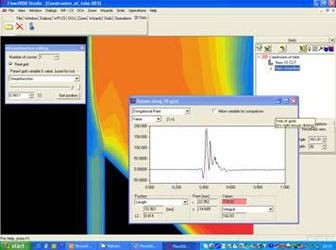

- Extrusion Flow Simulation

- MFR/MVR

- DSC

- TGA

- Instrumented Impact

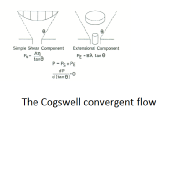

- Elongational Viscosity

- Compuplast VEL distributor

Filter products and services

-

Rheology Training and Interpretation

Rheometry training is essential if the best use is to be made of what are very complex instruments. Many field leaders are requesting assistance with tuition on both rheometry fundamentals and the more sophisticated techniques such as wall slip, elongational viscosity and elasticity. A highly sophisticated technique such as rheometry can often see instruments unused for enough time that operators forget how to use the machine or, personnel leave and new operators have to get up to speed. In both scenarios courses can be tailored to train or retrain key personnel to the level required.Request a Quote Supplied by Fleming Polymer Ltd -

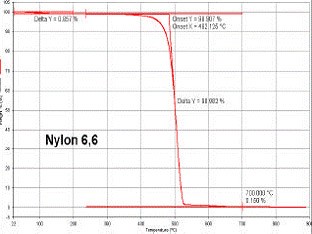

TGA

We offer thermogravimetric analysis (TGA) which measures the amount and rate of change of mass loss of a sample as a function of temperature and time in a controlled atmosphere. Thermogravimetric analysis is suitable for measuring:

- Compositional analysis of multi-component materials or blends

- Thermal stabilities

- Oxidative stabilities

- Estimation of product lifetimes

- Decomposition kinetics

- Effects of reactive atmospheres on materials

- Filler content of materials

- Moisture and volatiles content

The system operates from ambient to 1000°C and has gas switching capability. Standard on-site gases are technical grade nitrogen and oxygen.

For more information, please see our video.

Request a Quote Supplied by Fleming Polymer Ltd -

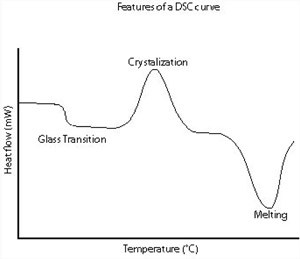

Thermal Analysis

At Fleming Polymer Testing and Consultancy, we supply a range of thermal analysis techniques that are used to characterise a variety of materials. One of our thermal analysis techniques is thermo gravimetric analysis or TGA, which measures the amount and rate of change in the mass of a particular sample by temperature or time in a controlled atmosphere (usually nitrogen or oxygen). This measurement is used to determine the thermal and oxidative stabilities of a materials, alongside its compositional properties.The TGA technique is particularly useful for:- Thermal stabilities

- Compositional analysis of multi component materials or blends

- Filler content of materials

- Moisture and volatiles content

- Decomposition kinetics.

Request a Quote Supplied by Fleming Polymer Ltd -

Thermogravimetric Analysis (TGA)

We offer thermogravimetric analysis (TGA) which measures the amount and rate of change of mass loss of a sample as a function of temperature and time in a controlled atmosphere. Thermogravimetric analysis is suitable for measuring:

- Compositional analysis of multi-component materials or blends

- Thermal stabilities

- Oxidative stabilities

- Estimation of product lifetimes

- Decomposition kinetics

- Effects of reactive atmospheres on materials

- Filler content of materials

- Moisture and volatiles content

The system operates from ambient to 1000°C and has gas switching capability. Standard on-site gases are technical grade nitrogen and oxygen.

For more information, please see our video.

Request a Quote Supplied by Fleming Polymer Ltd -

Wall Slip

Slip flow in the processing of polymers may be either beneficial, and actively encouraged by the addition of process additives, or detrimental, for example relating to the occurrence of flow instabilities. However, the occurrence of slip results in complications in both the measurement and modelling of the flow behaviour of materials. Reliable characterisation of the rheological behaviour of materials is important; whether it is for developing new materials with specific flow properties, design of injection moulding and extrusion processes, or for quality control of materials. This measurement is available via capillary rheometry and uses the Mooney method for the calculation of slip velocities from the experimental data.Request a Quote Supplied by Fleming Polymer Ltd