Fortress enters the fast lane with new multi-aperture metal detector range

20 January 2017Fortress Technology has designed a game-changing multi-aperture, multi-lane metal detector range, assisting food manufacturers to reduce factory footprint, investment and ongoing operating costs. Already successfully installed in two, four and five lane configurations by several leading UK food factories the production benefits and cost efficiencies of this new concept is believed to be the first technology of its kind.

Featuring a single metal detector mounted across multiple food packing and processing conveyor lines, the Fortress unit is uniquely divided into individual apertures, setting a new industry standard for performance. Because there’s a dedicated aperture for each lane, the range is more sensitive to smaller metal particles, detecting all metal types down 0.7 mm ferrous, 0.7 mm non ferrous and 1.4 mm stainless steel. In addition, this smaller aperture copes better with orientation and product effect.

By consolidating this multi-aperture technology into one unit spanning multiple lanes, opposed to individual metal detectors, cuts the equipment footprint by over 50%, optimising factory floor space. The unit also sharpens operational efficiencies, reducing initial investment costs for food processors and packers by up to 40%. With just one system to maintain and manage, longer term, the multi-aperture device improves total cost of ownership (TCO) by over 65%.

Compact system that fulfill all performance specifications

Until now, factories wanting a multi-lane system to inspect food items had limited options, emphasises Fortress’s European Sales Director Phil Brown. “You could either install a much larger single aperture spanning all lanes, or insert standalone metal detectors between the conveyors. Neither were ideal solutions for food factories, resulting in a bulkier machine or conceding on metal detection sensitivity.

“The main downside of installing a larger metal detector with a single aperture is it compromises product integrity. This is because the larger aperture is looking for metal contaminants in multiple products and dealing with multiple signals, making it less sensitive,” explains Phil. “Also, if a contaminated product is identified on one line, all products in the row are rejected, as the machine cannot single out the line with the contaminated product.” In comparison, the multi-aperture system only inspects and rejects contaminated products from the individual conveyor, which in a five-lane system cuts false product rejects by 400%.

The other alternative - slotting individual metal detectors between each conveyor - is a more costly investment option, both at the initial outlay and to maintain for the lifetime of each machine. It also doubles the system’s footprint, even when the metal detectors are staggered. “Compactness and lifetime TCO are top purchasing criteria for virtually all food processors today. This multi-aperture innovation ticks every box and delivers the very best in metal detection performance,” notes Phil.

A single control panel manages all lanes, streamlining operator access and enabling production managers to select and view data by individual lane, as well as analyse comparative lane data side-by-side. To increase production efficiency, each lane is programmed to run independently from each other. So, if one lane stops working or requires maintenance, the remaining continue to run as normal, minimising business interruption.

Meat burgers, chilled salads, personal care products, and spices are among the applications already benefiting from the multi-aperture, multi-lane technology. “Now we have a tried and tested system in two, four and five lane configurations, we can confidently engineer a unit for any number of lanes to inspect any product,” claims Phil. “Customers are repeatedly seeking food inspection systems that simplifies the purchase and support, reduces the volume of systems on the factory floor and optimises space, without compromising on quality and metal detection performance.”

Ferrous only five-lane combination system … another world first

Most recently, Fortress collaborated with Sparc Systems to design a Ferrous-only five-lane multi-aperture metal detector. This totally unique application was customised to inspect foil spice packs and integrated with a five-lane Sparc checkweigher. For Fortress, this installation was deemed a real engineering triumph, with the multi-aperture technology being integral to the project’s success.

The entire five-lane combination metal detector and checkweighing unit measured 1.5 metres wide by 2.2 metres lengthwise. “As far as we are aware, no one has ever accomplished such a compact combined system integrating a multi-aperture metal detector head. All other options would have meant compromising on either space, metal detection sensitivity or waste, making this project a non-starter.”

Custom built in 12 weeks and installed in March 2016, the five-lane system boosted inspection throughput from 200 to 1000 packs a minute, increased metal detection sensitivity by over 300% and reduced equipment footprint by over a half. It cost approximately £40,000 less than acquiring five individual metal detector and checkweighing combination systems. Another unrivalled feature is the transport mechanism that automatically separates metal contaminant rejects from weight rejects and places them in accessible BRC-approved lockable bins.

Challenging the status quo

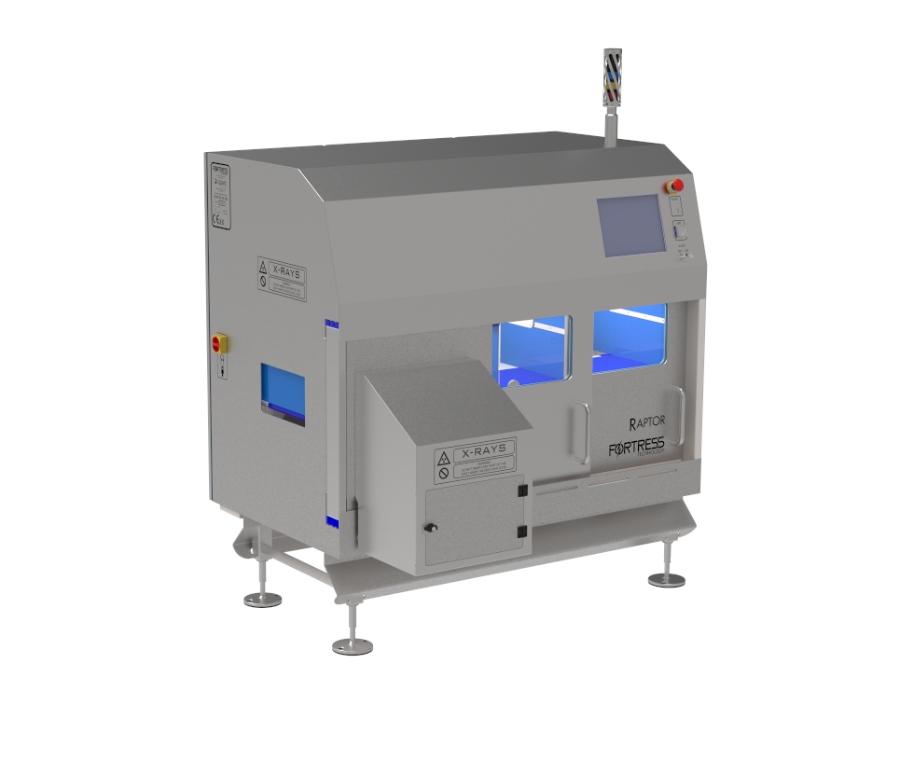

“Due to the foil packaging, x-ray might have been considered the only option. Yet, the small footprint meant it would be technically impossible to accomplish a fully integrated five-lane checkweigher and inspection unit with today’s x-ray technology,” says Phil.

How the spices are processed was another swing factor for multi-aperture. Phil explains: “This Ferrous-only system can identify metal contaminants measuring 1.2mm, compared to 5mm on a single aperture metal detector covering each line. While the risk obviously needs to reflect the product, when you consider the processing involved in preparing these spice blends, increasing the sensitivity to catch smaller wire swarfs that might pass through a sieve is huge advancement.”

Engineering a multi-aperture, multi-lane metal detector that fulfils all of the retailer performance specifications is a huge industry breakthrough, adds Phil. “We are very excited about the cost and performance benefits that this technology presents to our customers. Fortress has once again challenged the status quo and generated a truly innovative system that marks the end of food factories compromising on any performance criteria, in particular metal detection sensitivity.”

ENDS