HACCP IDEALS FOR PRE-PREPARED MEALS

5 February 2024Chilled and frozen convenience foods typically have more processing phases than any other food item. Although catching contaminants at the start of any food processing line is the most cost-effective solution, it is critical to assess and regularly review production risks in full context. Ensuring there are no HACCP gaps and that all of the essential inspection points are covered.

Phil Brown, Managing Director at Fortress Technology Europe examines the benefits of having a longer-term strategic investment plan; the hidden and frequently overlooked risks on pre-prepared food processing lines; ways to prevent, eliminate or reduce microbiological, hygiene and physical contaminants; and how to spread machinery inspection assets out across production lines so there are no HACCP-holes.

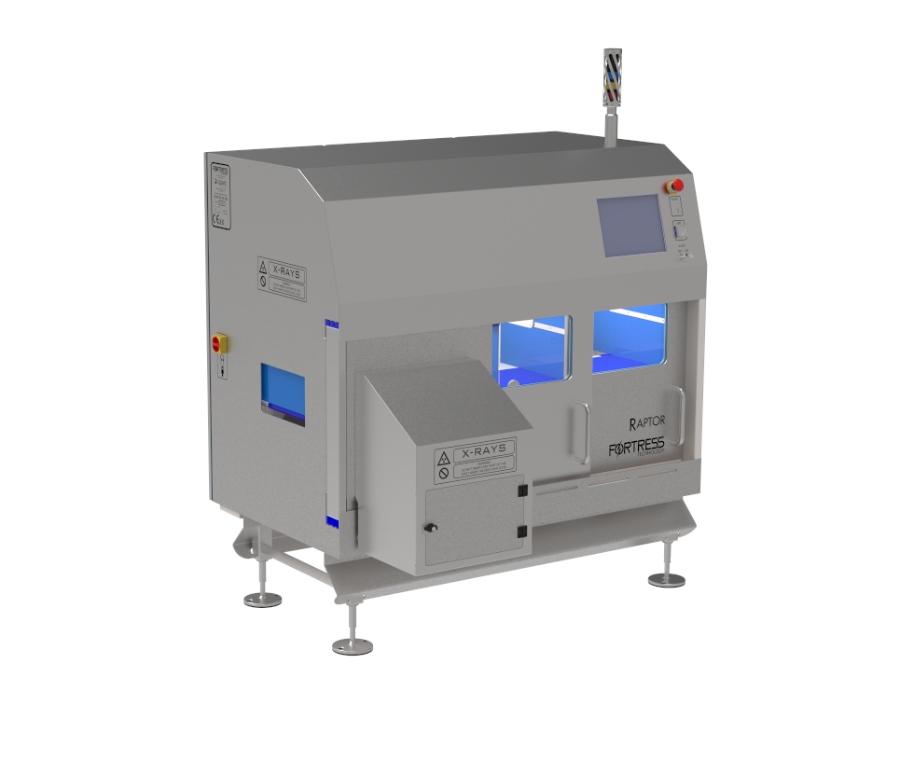

Although Metal Detectors inspect for the most-likely contaminant risk, X-Ray equipment may be utilised to detect non-metallic contaminants, e.g. bones. This is more common for premium meals or prepared foods targeted at young children or the elderly.

The number-one requirement for all food manufacturers is to ensure products are safe for consumption. Inspecting products after packaging using an end-of-line Metal Detection and/or X-Ray system is the most important CCP. It is also a retailer COP requirement.

The most common high-risk contamination culprit in food processing remains metal. However, X-Ray machines, including X-Ray pipelines may be advisable if there are specific risks. Foil packaging, such as metal trays, may influence the type of machine selected too.

Before shipment, processors of prepared foods also need to verify their products are the correct weight in order to comply with global Weights and Measures Regulations. A Checkweigher can be integrated with both Metal Detectors and X-Ray to ensure each product meets the nominal weight. Using a retail-spec combination systems can also ensure compliance with individually-defined COPs. Mounting a Checkweigher on the same conveyor as a Metal Detector or X-Ray results in a far smaller footprint than stand-alone units would occupy.

HACCP guidance states that critical control points (CCPs) should be located at any step where hazards can be prevented, eliminated, or reduced to acceptable levels. Every food processors’ needs are different. The same applies to products.

Rather than looking for patterns, examine potential CCP-holes. This is even more critical if a production process or packaging is changing. An annual HACCP assessment – a requirement for most convenience food facilities – will help to ensure all essential inspection points are covered and, most importantly, retail-compliant.