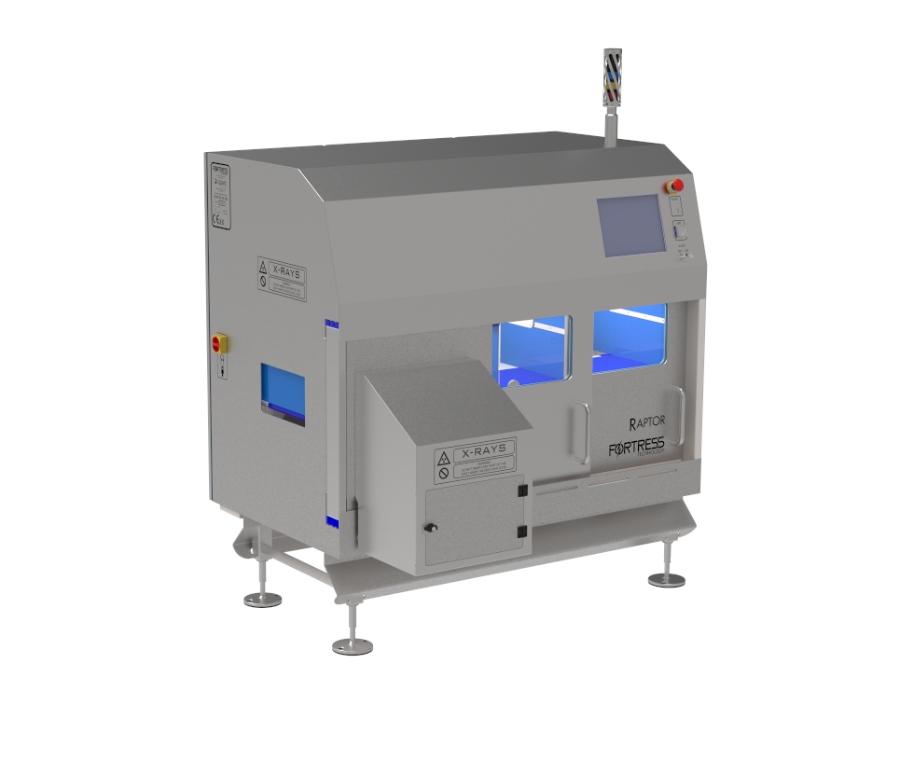

RAPTOR GETS ITS RETAIL-SPEC WINGS

11 June 2021Fortress Technology’s latest Raptor combination machine now comes with every UK supermarket Code of Practice specification pre-programmed into the machine. Exciting new features include a walk-through COP guide and easy-to-follow animated metal detector test screens.

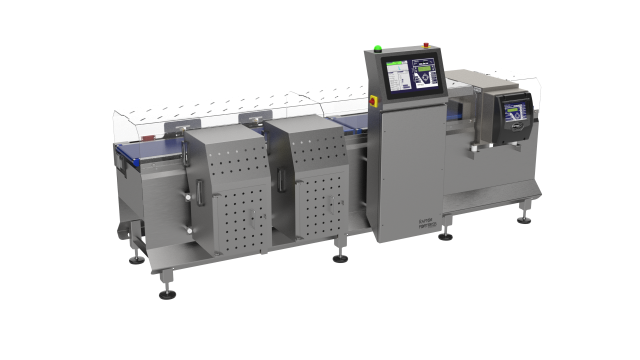

Designed to ensure full compliance with retailer Codes of Practice (COP), the fully-integrated Checkweigher and Metal Detector is currently Fortress Technology’s most in-demand machine. Prioritising food safety, the Raptor Combi features state-of-the-art metal detection infeed, outfeed, reject, bin full and bin door lock sensors, covering every phase of the inspection process.

Compared to other combination systems on the market, the retail-spec Raptor Combi always prioritises metal detection performance and automatically addresses application-specific product effect.

Another unique Raptor feature is its override option. Because the metal detector directly controls its own reject device and monitors its own sensors, food processors can quickly remove the checkweigher motor control and run it as a conveyor or independent metal detector. This is essential for maintaining HACCP inspection compliance as it allows processors to continue shipping products, regardless of the checkweigher status.

If any retailer COP changes, Fortress offers a simple and cost-effective route to adhere to evolving compliance and fault warning risks. These software upgrades are usually offered during a validation or routine maintenance visit. For operational continuity, the menu and functional set up typically looks and feels exactly the same.

The Raptor Combi is built from a robust stainless-steel frame coupled with a transparent polycarbonate interlocked cover. Engineered cutouts help to prevent airflow negatively impacting weighing accuracy. For high washdown food production areas, a stainless steel cover can be requested.