Fortress Technology (Europe) Ltd

Fortress Technology puts consumer safety first. In a world where better is just around the corner, we’re trusted by thousands of global manufacturers to design, build, install & maintain inspection equipment that deliver exactly what they promise. From food to FMCG; pharmaceutical to bulk; SMEs to listed companies; metal detectors to checkweighers; x-ray to combination systems; Fortress machines are designed to catch contaminants, slash waste, spot product defects, comply with weights legislation & reduce production downtime -wherever in the world you manufacture or export to. We regularly design systems that slot straight into existing production and packaging lines. For 20+ years we have offered the Fortress ‘Never Obsolete’ guarantee, ensuring future sustainability & compliance with HACCP & Codes of Practice. Now, this guarantee extends across all our new inspection systems.

Filter products and services

-

Metal Detection Systems

Fortress Technology’s metal detection systems are custom manufactured to suit any application. The metal detection systems uses digital signal processing technology and has high sensitivity level to ensure the detection of the smallest ferrous, non ferrous and stainless steel contaminants.

Request a Quote Supplied by Fortress Technology (Europe) Ltd -

Pharmaceutical Metal Detectors

Pharmaceutical metal detectors are designed for the inspection of individual tablets and capsules that are gravity fed through the product chute.

Stealth Pharmaceutical metal detectors are custom manufactured to suit Pharmaceutical and/or Nutraceutical applications. Stealth detectors use digital signal processing technology and have high sensitivity levels to ensure the detection of the smallest ferrous, non-ferrous and stainless steel contaminants. The built-in data collection software with USB connectivity establishes the Stealth as an effective critical control point complying with stringent HACCP regulations.

Please contact us on T: 01295256266 or sales-uk@fortresstechnology.com for more information.

Request a Quote Supplied by Fortress Technology (Europe) Ltd -

Pipeline Metal Detector

Stealth Pipeline metal detectors are custom manufactured to suit any piped product application. The Stealth uses digital signal processing technology and has high sensitivity levels to ensure the detection of the smallest ferrous, non-ferrous and stainless steel contaminants. The built-in data collection software with USB data transfer establishes the Stealth as an effective critical control point complying with stringent HACCP regulations.

Suitable for the following applications:

- Dairy

- Soups & Sauces

- Juice

- Jam

- Meat

Please contact us on T: 01295256266 or sales-uk@fortresstechnology.com for more information.

Request a Quote Supplied by Fortress Technology (Europe) Ltd -

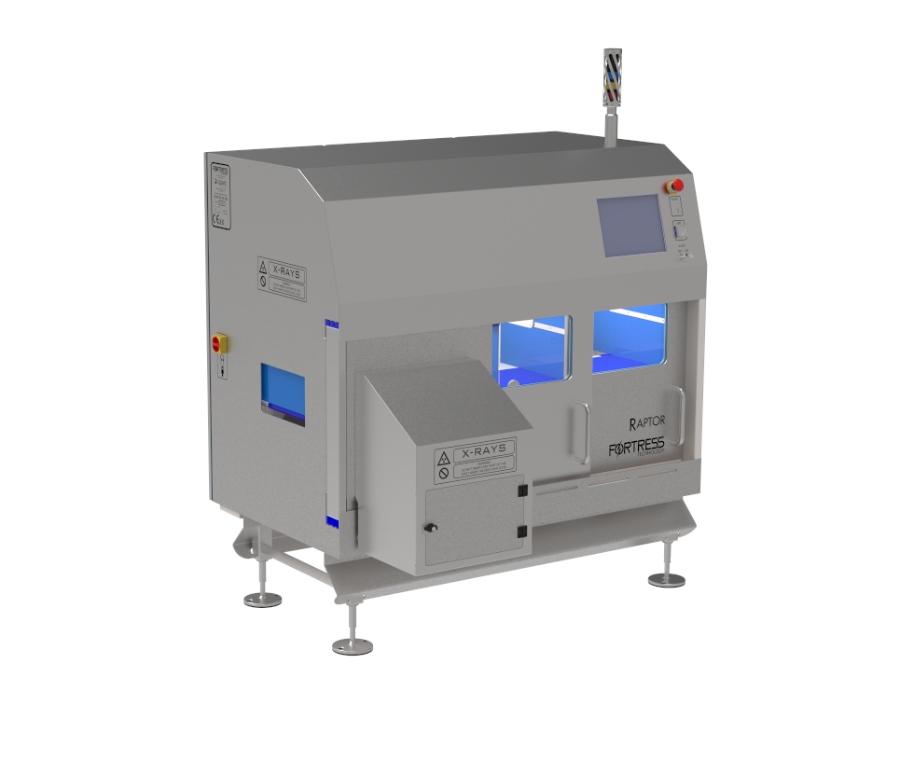

Raptor Checkweigher

The Raptor is a highly accurate, fully integrated checkweighing system, specifically designed for high care food production environments.

The Raptor is employed to verify the weight of each product and reject non-conforming packs. The system has been designed, engineered, and constructed to the highest care/food grade engineering standards. It is capable of processing packaged products up to 8 kg.

Raptor can be used at any stage in your process to inspect safely, reliably, and accurately 100% of your products.

Request a Quote Supplied by Fortress Technology (Europe) Ltd -

Raptor Combi

For manufacturers where traceability is paramount, the Raptor Combi is a new fully integrated metal detection and checkweighing system developed by Fortress Technology and Sparc Systems in a collaborative first. This next evolution inspection system features ground-breaking compliance control software to ensure the highest quality of inspection.

Modular in design, the Raptor can be used standalone or easily integrated with a metal detector for a sleek combi system. Placed at any stage of your process, the Raptor runs at 150 packs per minute while accurately inspecting products weighing up to 8kg and 300 x 400mm in size. Programmed measurements allow operators to quickly view live data regarding product weight, batch weight and giveaway to verify that product is running within set tolerances. Both checkweighing and metal detection can be optimised through the same monitor and remotely accessed.

If you supply the supermarkets, the Raptor’s compliance control software will ensure every COP (Code of Practice) is being met. All COP and product specifications are programmed into the control system which in turn alerts an operator at a scheduled time. This prompts a step-by-step auditing procedure and requires a signatory before results can be made available through USB download or uploaded automatically to your server. This system prevents skipping tests and tampering with results by notifying a manager. If any COP changes, our “Guaranteed Sustainability” commitment provides you with the latest software to keep you up to date for the lifespan of your machine.

Request a Quote Supplied by Fortress Technology (Europe) Ltd -

Raptor XL Caseweigher

The Raptor XL is a highly accurate, fully integrated caseweighing system, specifically designed to suit any large bag or case application.

The Raptor XL is employed to verify the weight of each product within tolerances or using another weighing system. The Raptor XL has been designed, engineered, and constructed to the highest care/food grade engineering standards.

Raptor XL can be used at any stage in your process to inspect safely, reliably, and accurately 100% of your products. Built-in data collection software with USB data transfer, OPC-UA and Ethernet/IP facilities (optional) allow for ease of production performance tracking and improvement of operational efficiency.

Request a Quote Supplied by Fortress Technology (Europe) Ltd -

Simultaneous Multi Frequency Metal Detector

Interceptor metal detectors are custom manufactured to achieve superior results in challenging applications. The Interceptor uses a simultaneous multi-frequency operation that effectively processes the transmission and reception of multiple frequencies continuously over a broad spectrum. This revolutionary operation facilitates an improvement in detection capabilities of up to 100% with stainless steel, especially when inspecting traditionally difficult “wet” products.

Suitable for the following applications:

- Meats

- Dairy

- Prepared Meals

Request a Quote Supplied by Fortress Technology (Europe) Ltd -

Stealth Big Bag Metal Detector

Stealth Large Bag metal detectors are custom manufactured to suit any large bag application. Stealth detectors use digital signal processing technology and have high sensitivity levels to ensure the detection of the smallest ferrous, non-ferrous and stainless steel contaminants. The built-in data collection software with USB data transfer establishes the Stealth as an effective critical control point complying with stringent HACCP regulations.

Suitable for the following applications:

- Flour

- Powders

- Grain

- Spices

- Bulk Products

Please contact us on T: 01295256266 or sales-uk@fortresstechnology.com for more information.

Request a Quote Supplied by Fortress Technology (Europe) Ltd -

Stealth Conveyor System

Vector Conveyor Systems have been developed to optimize the performance of Fortress Metal detectors. Custom built to suit the detector and the application; Vector Conveyors are manufactured from Stainless Steel and are suitable for harsh wash-down environments. Choose from a variety of reject systems, belt sizes, belt configurations and sensors to maximize detector accuracy.

Please contact us on T: 01295256266 or sales-uk@fortresstechnology.com for more information.

Request a Quote Supplied by Fortress Technology (Europe) Ltd -

Stealth Food Metal Detector

Stealth metal detectors are custom manufactured to suit any application. The Stealth uses digital signal processing technology and has high sensitivity levels to ensure the detection of the smallest ferrous, non-ferrous and stainless steel contaminants. The built-in data collection software with USB data transfer establishes the Stealth as an effective critical control point complying with stringent HACCP regulations.

Please contact us on T: 01295256266 or sales-uk@fortresstechnology.com for more information.

Request a Quote Supplied by Fortress Technology (Europe) Ltd