Tomorrow’s Engineers Week: Q&A with Karmelle Ltd’s Workshop Manager

6 March 20204th – 8th November is Tomorrow’s Engineers Week, a five-day long campaign launched to celebrate the changing face of the industry and inspire a new generation of creators. Engineering is what we do here at Karmelle Ltd, and we couldn’t miss the opportunity to celebrate our own fantastic team. First up, a Q&A with newly appointment workshop manager Dave. A busy dad with a passion for vintage camper vans, he’s always enjoyed making things…

Dave, tell us how long you’ve worked in the engineering industry.

I have worked in engineering for around 17 years now. I cut my teeth as an engineer at a textile mill when I was 18. I went to college once a week for 3 years, where I earned an advanced diploma in maintenance engineering.

After working there for around 7 years I needed more of a challenge and left to work in the development department for a high-end bed company, where we developed new machinery that pocketed springs into fabric and even trainers for a leading sports brand.

Leaving there after 4 year brought me back into a maintenance role at a large paving company whose products are seen throughout UK towns and cities. It was there that I learnt engineering on a larger scale, as the machines were big and very industrial.

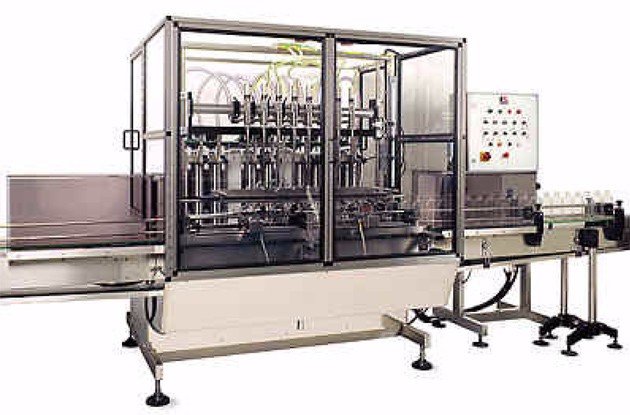

That brings me to Karmelle Ltd. I’ve been at Karmelle Ltd for just over 2 1/2 years, working with a team of engineers to build filling and capping machines and assist with on-site support and installations.

Why did you decide to pursue a career in engineering?

I was offered an apprenticeship in engineering when I was 18 and jumped at the chance. From a young age I was always taking things to pieces and building new projects, so being an engineer made total sense to me.

What’s your favourite aspect of the job?

My favourite aspect of the job is seeing a new idea or concept getting developed, and then seeing it come to life on the shop floor.

What does the future hold for the sector?

I think that the sector will progress in terms of faster, more intelligent equipment to run our machines. However, stripping all that back, you still need the nuts, bolts, bearings and other components to hold everything together, and I think these fundamentals will never change. I think development plays a big role in engineering, and the need to improve or make things more efficient drives the industry forward. Looking for ‘greener’ and ‘low cost’ solutions to run our technology is also key in manufacturing today, and we could see changes in the way we power our homes and factories in the future.