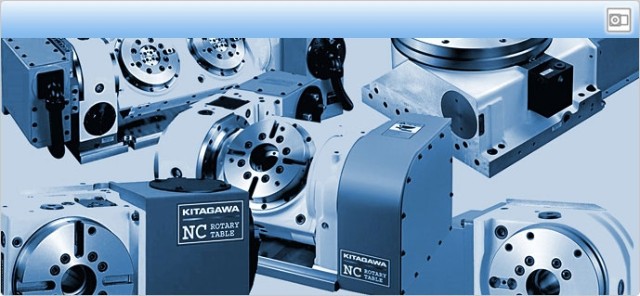

MK200 Rotary table - the start of an upgraded standard series to suit your machine.

13 August 2019The MK200 is an intelligent design to meet the future requirements that the industry demands from a 4th axis rotary table. Kitagawa's focus has been to improve the standard of their rotary tables in three areas:

- Enhanced Performance

- Improved Mounting

- Wide Selection of Rotary Joints

Enhanced Performance

The clamping torque of the MK200 has improved to 570N.m from the older standard of 350N.m of the MR200 rotary table which is an increase of 40%. In addition, Kitagawa has made the depth of the rotary table 10% thinner than the previous MR200 Rotary table to only 155mm deep and has increased the spindle through hole to 70mm from 45mm of the MR200. By incorporating friction-welding procedures into their manufacturing techniques and combining this skill with their design capabilities from many years of experience Kitagawa has delivered a performance balanced new standard of rotary table to the future market. Of course, it must be mentioned that Kitagawa has other stronger (GT200) and more compact (CK200) rotary tables in their product range but the MK200 is designed to meet 90% of customers needs and in most cases will be suitably strong enough to withstand various machine cutting conditions demanded of it.

After rigorous testing the MK200 adheres to the same standard of clamping torque test required of ALL Kitagawa rotary tables. The 570N.m of clamping torque is determined as the force at which 30 microns displacement of the worm wheel diameter occurs. Kitagawa determines displacement above this to be a failure as the accuracy you demand from Kitagawa tables cannot be maintained. This is markedly different from many of our competitors who use the 'pull-out torque' or slipping torque figure to determine their maximum torque. Kitagawa view slipping torque as a catastrophic and dangerous failure if you have pushed a rotary table to this extreme. So you can rest assured that even if you do push your Kitagawa table to its limitations of the clamping torque indicated in the instruction manual then your Kitagawa table will maintain its accuracy where others fail. This increase to the standard clamp torque significantly increases the allowable cutting torque your machine is able to deliver to the workpiece, reducing takt time to increase your productivity. The MK200 also maintains the highest rotating/drive torque capability in its size and class of rotary table (270 N.m) due to a large worm wheel diameter design enabling you to produce complex workpieces with speed and accuracy.

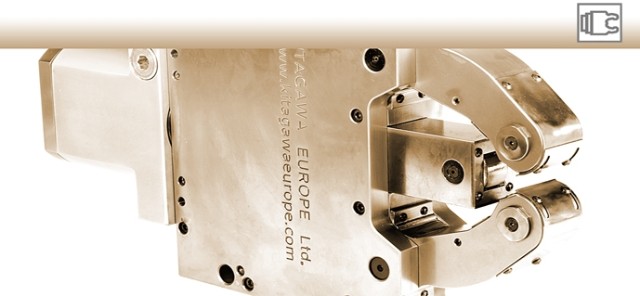

You will notice that the MK200 rotary table is supplied without a standard faceplate which will allow you to specify exactly what type of face plate you require - with t-slots or standard pre-drilled holes like the current MR200 rotary table. The major advantage of this is that a chuck, trunnion bed or any workholding device can be mounted directly onto the rotary table's spindle, reducing the distance from the spindle bearing. This compact assembly reduces the loading to the spindle bearing therefore increasing the rotary tables rigidity and longevity.