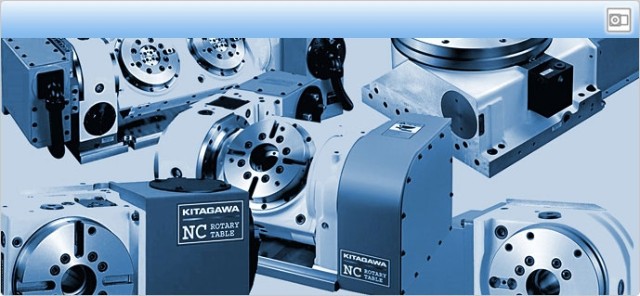

NC ROTARY TABLE CONTROLLER

3 March 2020Kitagawa’s latest independent rotary table control system called the ‘Quinte’ is a major upgrade from their venerable ‘Mac Mini’ system. The Quinte series comes in three model types - the QTC100 for single axis rotary tables, the QTC200 for double axis rotary tables and finally the QTC300 for larger single axis rotary tables with faceplate diameters of more than 320mm. Additionally each type of Quinte has various motor size options to best suit Kitagawa’s large range of rotary tables, allowing for the perfect solution catered to your machining conditions. The major advantage of installing an independent rotary table control system is that your rotary table can be used on multiple vertical machining center on your shop floor.

Connected with your machines M-code and safety circuits allowing either standard indexing or synchronised machining (machining whilst the rotary table is rotating)

The Quinte series has been designed with ease of use and high speed performance in mind. By adopting high speed EtherCAT technology, the Quinte series reduces indexing time with instant communication from Quinte to the rotary table.

Programs can be rapidly& written on a& computer before being uploaded onto a multimedia card (or SD Card) and transferred directly into the front of the Quinte unit. Adjustments to your program and parameters can be easily conducted via the Quinte’s interactive touch panel display. The Quinte’s high resolution screen makes operating much more intuitive by clearly displaying the current position, the program that is running, motor information and more.

The manual operation pendant allows precise manual control for the quick setup of origin positions and also conveniently displays position or program information to reduce setup times.

With the remote-control option, you can use the CNC control on your machine and macro programming to directly send indexing commands to the Quinte, via the RS232 cable. There is no need to have separate programmes on the machine and the Quinte. Lines of the macro program are automatically transferred from the machine through the RS232 cable to the Quinte, when the Quinte receives a start signal from the machine M-Code it will execute one line of the macro program. When the communication protocols and signals are setup correctly there should be no need for the machine operator to interact with the Quinte.