Kitagawa Europe Ltd

Specialist Suppliers of Rotary Tables, Power Chucks, Work Grippers and More

Established over 70 years ago, Kitagawa have produced products for machine tool accessories, building materials, foundry and construction equipment.

Kitagawa's Europe's core product range currently includes, Rotary Tables, Power Chucks, Hydraulic Cylinders and Collet Chucks. Kitagawa's dedicated team of specialist engineers are constantly working on new and innovative design solutions.

Filter products and services

-

B-212A8 (Open Centre Chucks/B-200A)

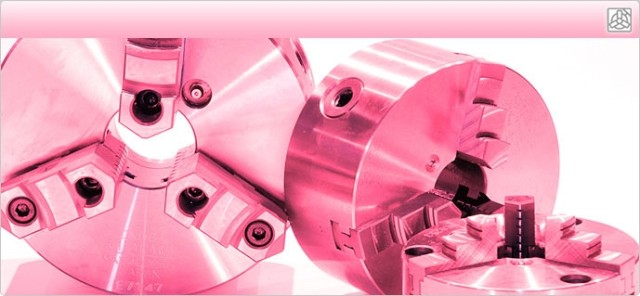

Chucks are manufactured from high grade alloy steel. Three jaw wedge style power chucks deliver up to 20% more speed, gripping force and bore size when compared to conventional chucks. * A2-8 Spindle Nose * Through-hole (mm): 91 * Gripping range (mm): 304 max, 34 min * Jaw Stroke (diameter mm): 10.6 * Plunger Stroke (mm): 23 * Max. Draw Bar Pull Force: 55kN, 5608 kgf * Max. Gripping Force: 144 kN, 14684 kgf * Max Speed: 3300rpm * Weight (with soft jaws) 64kg * Moment of inertia: 0.765 kg.m2 * Matching cylinder: S2091 * Max pressure: 2.7 MPa, 27.5 cm2 * Matching hard top jaw: HB12N1 * Matching soft top jaw: SB12N1 * Optional soft jaws: KSJ 212Request a Quote Supplied by Kitagawa Europe Ltd -

B-212 (Open Centre Chucks/B-200)

Chucks are manufactured from high grade alloy steel. Three jaw wedge style power chucks deliver up to 20% more speed, gripping force and bore size when compared to conventional chucks. * Through-hole (mm): 91 * Gripping range (mm): 304 max, 34 min * Jaw Stroke (diameter mm): 10.6 * Plunger Stroke (mm): 23 * Max. Draw Bar Pull Force: 55kN, 5608 kgf * Max. Gripping Force: 144 kN, 14686 kgf * Max Speed: 3300rpm * Weight (with soft jaws) 55.3kg * Moment of inertia: 0.738 kg.m2 * Matching cylinder S2091 * Max pressure: 2.7 MPa, 27.5 cm2 * Matching hard top jaw: HB12N1 * Matching soft top jaw: SB12N1Request a Quote Supplied by Kitagawa Europe Ltd -

B-215 (Open Centre Chucks/B-200)

Chucks are manufactured from high grade alloy steel. Three jaw wedge style power chucks deliver up to 20% more speed, gripping force and bore size when compared to conventional chucks. * Through-hole (mm): 100 * Gripping range (mm): 381 max, 50 min * Jaw Stroke (diameter mm): 10.6 * Plunger Stroke (mm): 23 * Max. Draw Bar Pull Force: 98kN, 9993 kgf * Max. Gripping Force: 249 kN, 25391 kgf * Max Speed: 2800rpm * Weight (with soft jaws) 116kg * Moment of inertia: 2.20 kg.m2 * Matching cylinder F2511H * Max pressure: 3.3 MPa, 33.7 cm2 * Matching hard top jaw: HB15N1 * Matching soft top jaw: SB15N1Request a Quote Supplied by Kitagawa Europe Ltd -

COLLET CHUCKS

At Kitagawa Europe we take seriously our responsibility to provide our customers with appropriate holding devices to complement our NC Rotary Tables. Collet Chucks are of course an integral part of the machining process when looking to produce the highest quality components, delivering numerous benefits: * Quick chucking for fast turn around * Self centring * High clamping force * Precise centring reducing runoff We realise that the demands of each application can vary widely and offer a range of Collet Chucks to meet our customers' requirements; whether they are looking for a time efficient Quick Change Collet Chuck or the supreme accuracy and compact design offered by a Pull Back Collet Chuck. When it comes to machining performance the Collet itself is just as important as the Collet Chuck. Fortunately at Kitagawa we have all the angles covered with an extensive range of Collets, available in every connection type: * Varibore Collets (D-671, D-850, D-673, D-120, D-677, D-285, D-175, D-660) * Spring Collets (D171E, D-286, D173E, D-853, D185E, D193E) * Pull Back Collets (5C, 16C) * DC Collets (DC-52, DC-65, DC-42) In order to keep your operation running at optimum levels, we also provide an excellent selection of accessories, from Grease Guns to Collet Changing Devices.Request a Quote Supplied by Kitagawa Europe Ltd -

HYDRAULIC CYLINDERS

For over half a century, KITAGAWA products have inspired confidence in customers all over the World. The Kitagawa series of power chucks is wide-ranging and so technologically advanced that we can offer solutions for all machining conditions, no matter how punishing. Manufacturing systems with exceptional quality controls ensure the production of highly precise and superior products, which guarantee trouble-free operation. Our unique innovations in workholding solutions, supported by highly specialised design teams and a proven history of excellence, shows our capacity to challenge the world of engineering.Request a Quote Supplied by Kitagawa Europe Ltd -

JN06T (3 Jaw Scroll Chucks/JN..T)

Steel body construction gives increased rigidity and improved durability, allowing for operation at high speed. * Max. static gripping force (kN): 31 * Max Speed: 3500rpm * Weight (kg): 13 * Moment of inertia (kg.m2): 0.063 * Gripping Range (outer): 4~180mm * Gripping Range (inner): 62~180mm * Matching Soft Jaws: SBS07 * Matching Hard Jaws: HBS07C * Handle torque (N.m): 107.9Request a Quote Supplied by Kitagawa Europe Ltd -

MANUAL CHUCKS

When it comes to gripping components, 3 Jaw Chucks tend to be the most popular thanks to their versatility. The Kitagawa 3 Jaw Chuck series offers the perfect option for every requirement, from large through hole diameter for large workpieces, to steel body construction for increased rigidity. Of course, 3 Jaw Chucks are not suited for every application and some situations may require a more specialised approach. We provide an extensive range of manual scroll chucks to suit your needs, whether it is 2 Jaw Scroll Chucks for gripping irregularly shaped components such as pipe joints and valves, or the huge clamping force delivered by 6 Jaw Chucks. When working on stock that is not perfectly concentric, our 4 Jaw Independent Chucks provide the ability to adjust gripping accordingly and ensure precision and conformity throughout.Request a Quote Supplied by Kitagawa Europe Ltd -

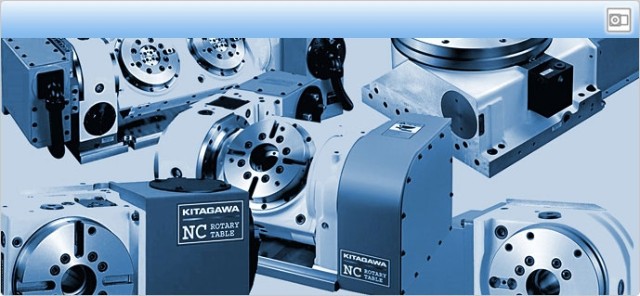

NC ROTARY TABLES

NC Rotary Tables are one of the product ranges that have helped secure Kitagawa's strong reputation for delivering high quality products. Their lasting build quality and precision engineering have ensured these rotary tables stand out above the competition. The Kitagawa range of rotary tables currently includes full 4th & 5th Axis rotary tables. We specialise in compact high speed rotary tables, NC Rotary Tables suitable for heavy machining and the compact multi spindle table to name just a few. Kitagawa's range of popular Mac Mini controlled rotary tables are also expanding and feature 4th or 5th axis controlled rotary tables with a Yaskawa motor and drive. In addition to complete NC Rotary Table units and Mac Mini controlled rotary tables, Kitagawa stock rotary table controllers, rotary table accessories and carry a complete range of rotary table spare parts which includes motors, cable plates, seals and pressure switches. As with all our products, Kitagawa Europe is committed to providing the very best in quality engineering and high levels of customer service.Request a Quote Supplied by Kitagawa Europe Ltd -

Power Chucks

For over half a century, KITAGAWA products have inspired confidence in customers all over the World. The Kitagawa series of power chucks is wide-ranging and so technologically advanced that we can offer solutions for all machining conditions, no matter how punishing. Manufacturing systems with exceptional quality controls ensure the production of highly precise and superior products, which guarantee trouble-free operation. Our unique innovations in workholding solutions, supported by highly specialised design teams and a proven history of excellence, shows our capacity to challenge the world of engineering.Request a Quote Supplied by Kitagawa Europe Ltd -

STEADY RESTS

When it comes to the production of thin shaft-type workpieces on turning machines, steady rests are a crucial accessory.Without the assistance of a steady rest there is the increased likelihood that workpieces will become unstable during the cutting process, which can cause them to bend or deflect; concentricity can be affected as can the quality of surface finish. The Kitagawa Europe steady rest range boasts the highest levels of build quality to ensure engineering accuracy and safety in the workshop. We supply a wide selection of standard and grinding steady rests that are designed for a variety of applications, including: * Fixed or travelling positioning * Vertical loading * Crank shaft turning * Actuating cylinder * Compact designs for tight work areas * Heavy duty models for components weighing 10-40 tonnes At Kitagawa Europe we take seriously our responsibility to continue delivering the very best in engineering products. Our range of steady rests come with quality assured which, as with all of our products, are backed by high levels of customer support.Request a Quote Supplied by Kitagawa Europe Ltd