Mactenn Systems Ltd

Mactenn Systems Ltd specialise in high quality, low-velocity, dense phase pneumatic conveying systems. Their pneumatic conveying systems are used worldwide in various process industries handing a diverse range of bulk materials. They are a sister company of Macawber Engineering Inc. in the US that has focused on pneumatic conveying for over 40 years. Mactenn is known for their expertise as well as the reliability of their technology.

Mactenn Systems Ltd's high quality range of pneumatic conveyors includes:

- Maxflo

- MultiAshflo

- Cementveyor

- MiniMaxflo

- Macpump and many more

Filter products and services

-

HMI Touch Screen Control

The control and diagnostics facility is provided for single or multiple reception systems. The facility provides the following operator friendly facilities.1. A 6" colour touch screen HMI with fully animated display of the system tailored to your requirements. Larger touch screen panels are available on request.2. Local and remote (SCADA) automatic operation capabilities via Ethernet connection.3. A manual control mode to allow safe operator intervention for recovering from an upset condition from a blocked line due to out of tolerance material or air failure.4. An complete alarm diagnostics page.5. On screen trends for peak performance review6. A record of system operating performance from a data logging facility.Request a Quote Supplied by Mactenn Systems Ltd -

Inflatek Valve®

Provides a reliable leak proof seal that prevents ultra fine powders as well as abrasive granules from seeping into vessels. A valve that requires low maintenance and simple inspection makes it easy on the whole process it is involved in.Request a Quote Supplied by Mactenn Systems Ltd -

Injection Systems

Here at Mactenn Systems Technology, we offer an extensive range of state-of-the art technology that provides engineering and design solutions when handling bulk material.

We pride ourselves on being able to offer solutions that meet and exceed your exact requirements when it comes to investing in one of our high performance injection systems. With over 20:1 turn down controls, we strive to deliver systems that can dramatically improve the way you conduct your work.

With the capability to provide a precise feed control into your incinerator or combustor, our systems allow you to utilise an +3% accuracy of a set feed control rate whilst overcoming varying back pressure and atmospheric setting, while feeding into a fluid bed combustor.

For more information about our extensive range of injection systems, please do not hesitate to contact us directly.Request a Quote Supplied by Mactenn Systems Ltd -

IV Switch Diverter Valve

Allows a single pipe route to be used even in the cases of multiple reception points. In some cases, applications with two pipelines can be reconfigured so that for one segment there could be a single line shared. Directs material promptly with fully automated controls.Request a Quote Supplied by Mactenn Systems Ltd -

L1 Single Reception Electrical Control

The control and diagnostics facility is provided for single reception MiniMaxflo and Maxflo systems. The facility provides the following operator friendly facilities: 1. A manual control mode to allow safe operator intervention for recovering from an upset condition from a blocked line due to out of tolerance material or air failure.2. An alarm diagnostics display by various flashing sequence from the alarm lamp.Request a Quote Supplied by Mactenn Systems Ltd -

L2 Single Reception Electrical Control

The control and diagnostics facility is provided for single or multiple reception systems. The facility provides the following operator friendly facilities.1. A full display of systems operating and efficiency indicators.2. A manual control mode to allow safe operator intervention for recovering from an upset condition from a blocked line due to out of tolerance material or air failure.3. An alarm diagnostics display by various flashing sequence from the alarm lamp.4. A record of system operating performance from a data logging facility.Request a Quote Supplied by Mactenn Systems Ltd -

Macpump®

When the tonnage required is great and the distance is hundreds of metres away. The control package for this model is fully automated. Materials that are abrasive are conveyed in a dense phase method which prevents pipe wear and high maintenance costs.Request a Quote Supplied by Mactenn Systems Ltd -

Material Handling

Mactenn Systems Ltd provide Material Handling services.

Request a Quote Supplied by Mactenn Systems Ltd -

Material Handling Conveyors

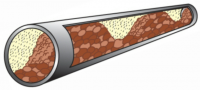

At Mactenn Systems we specialise in the design and supply of material handling conveyors for use in any type of industrial setting. We have been operating for 35 years and have gained the experience of operating on over a thousand installations. Our engineers can help you to determine which pipeline and conveying systems will suit the nature of your material.

The texture, density and temperature of the material will point us in the direction of certain types of conveyor. At Mactenn we use dense phase pneumatics rather than dilute phase conveying. This means we transfer the material at low velocity for a more gentle process to ensure there is no damage or degradation to the substance.

Contact us for more information on our Material Handling Conveyors.Request a Quote Supplied by Mactenn Systems Ltd -

Maxflo®

Its innovative yet simple design is the reason it is so versatile in bulk material conveying. Having only one moving part, it is low on maintenance and does not consume manpower or energy in its operation. Fully compliant with ATEX standards and can meet the high temperature needs of many processes.Request a Quote Supplied by Mactenn Systems Ltd