Mactenn Systems Ltd

Mactenn Systems Ltd specialise in high quality, low-velocity, dense phase pneumatic conveying systems. Their pneumatic conveying systems are used worldwide in various process industries handing a diverse range of bulk materials. They are a sister company of Macawber Engineering Inc. in the US that has focused on pneumatic conveying for over 40 years. Mactenn is known for their expertise as well as the reliability of their technology.

Mactenn Systems Ltd's high quality range of pneumatic conveyors includes:

- Maxflo

- MultiAshflo

- Cementveyor

- MiniMaxflo

- Macpump and many more

Filter products and services

-

Maxsandflo®

Specially designed to provide transfers of abrasive gritty materials in a compact, low profile vessel. Using low velocities, harsh materials do not wear out the pipe route easing maintenance concerns.

Key Features:

Achieves transfer of abrasive materials without causing excessive wear to the pipeline.

Requires much less conveying air which translates to smaller compressors and smaller exhaust filters.

Unique top discharge port combines a vessel and a vertical bend in one package making it able to be installed in shallow locations or pits. Remotely mounted control panels means the vessel can go where you do not want to.

Totally enclosed system provides a dust free work environment.

Worldwide installations of many thousands of Maxsandflos many still in service after decades of operation.

Request a Quote Supplied by Mactenn Systems Ltd -

Minerals Conveying

At Mactenn Systems, we design, manufacture, and deliver, an extensive range of pneumatic conveying systems and Inflatek Valves that provide solutions to all of your mineral processing requirements.

We have a wealth of knowledge and experience when it comes to delivering materials such as coal, ores, ground concentrates, and pebble lime across great distances. Our mineral conveying products allow you to efficiently and reliably transfer materials from one point to another. Thanks to our expert engineers, our systems require considerably less maintenance and, as such, improve the productivity of your staff.

For further information about our mineral conveying products, systems, and services, please do not hesitate to contact us.Request a Quote Supplied by Mactenn Systems Ltd -

MiniMaxflo®

Allows the convenience of a fully automated system in the places hard to reach. The short and compact design provides material transfer with low energy consumption. The totally enclosed vessel creates a dust free environment and it fully automated controls can be operated remotely.Request a Quote Supplied by Mactenn Systems Ltd -

MultiAshflo®

With its low profile, it is able to squeeze in tight spots where dilute phase systems can not go. This model can handle the rigors of transporting ash with temperatures as high as 3500C. A variety of ashes ranging from the light biomass ash to the gritty waste fuels ash are easily handled and transferred using a single pipeline from multiple feed points.Request a Quote Supplied by Mactenn Systems Ltd -

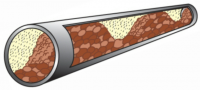

Pneumatic Conveying

Dense phase pneumatic conveying is a method of transferring material in bulk from one site to another. It provides you with major benefits compared to using a method such as dilute phase conveying. For a start, with dense phase pneumatic conveying the transfer is carried out at low velocity so doesn't place stress on the material itself.

That makes it ideal for conveying hazardous or fragile materials. And it makes it a much more cost-effective solution than dilute phase conveying. It's also highly versatile, and can be used whether you're looking to transfer material in powder, granule, or lumpy forms. At Mactenn Systems we have a full range of pipelines and conveying systems for any type of material.

Just contact us for more details of our Pneumatic Conveying Systems.Request a Quote Supplied by Mactenn Systems Ltd -

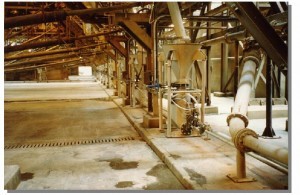

Pneumatic Conveying Systems

At Mactenn Systems Ltd, we design, produce, and deliver highly specialised pneumatic conveying systems. We offer a wide range of services and solutions that meet all of your bulk handling requirements.

Our pneumatic conveying systems incorporate a vast range of carefully developed products including the MultiAshflo, which can convey ash at temperatures of up to 350 degrees Celsius, the Variflo for systems that are required to convey large amounts at large distances, and the fully automated MacPump.

If you require any additional information about our expertly developed pneumatic conveying systems, please do not hesitate to contact us.Request a Quote Supplied by Mactenn Systems Ltd -

Pneumatic Conveyors

At Mactenn Systems, we are experts in dense phase pneumatic conveying. Employing our wealth of industry knowledge and professional experience, we have developed a range of pneumatic conveyors that will meet all of your requirements.

Our pneumatic conveyors include the Inflatek Valve, which creates a leak proof seal preventing ultra-fine powders from seeping into vessels, Cementveyor, which specialises in the long distance conveying of cement, and the Maxsanflo, which allows abrasive products to be conveyed with low velocity.

For further information about our extensive range of pneumatic conveyors, please do not hesitate to contact us.Request a Quote Supplied by Mactenn Systems Ltd -

Pneumatic Design Conveying

At Mactenn Systems our bulk material conveying equipment is based on dense phase pneumatic technology. We can design and install systems for you that provide superior performance to conventional dilute phase equipment. Our dense phase pneumatic conveyors provide low velocity transfer of material that puts much less strain and stress on the material itself.

This avoids damage and enables our systems to deliver hazardous, abrasive or particularly fragile materials. The material can be conveyed in powder, granule, or lump form with various pipework options available depending on the material type and the level of pressure required to carry out the transfer.

Contact us for more information on Pneumatic Conveyor Designs.Request a Quote Supplied by Mactenn Systems Ltd -

Pressure Valves

At Mactenn Systems we can provide pressure valves to form an integral part of any dense phase conveying system. Our Inflatek Valves can be supplied in sizes of between 2 up to 30 inches and in cast iron, stainless steel, or carbon steel depending on your requirements. The pressure valve will maintain a seal on a 100 per cent vacuum application.

The valves are designed to be low maintenance and can be used in applications of temperatures up to 350 degrees Celsius. They are designed and manufactured fully in accordance with ASME Section VIII Div 1 and PED, GB150.

Contact us for more information on our Pressure Valves.Request a Quote Supplied by Mactenn Systems Ltd -

Pressure Vessels

Mactenn Systems Ltd supply Pressure Vessels.

Request a Quote Supplied by Mactenn Systems Ltd