Spill Response and How It Works

8 September 2021Following specific procedures when cleaning up hazardous spills is critical to employee safety and facility safety. Make sure everyone knows the specific role they play in this process.

Most types of companies have hazardous chemicals, and all employees should know what to do in an emergency or cleanup situation. There are specific programs and specific employees assigned to these programs. If done correctly, these procedures can save lives, injuries, and property.

In most cases, the first person to report a leak is a incident responder who will not involved in the actual cleanup. Once reported, the Health and Safety Officer is responsible for ensuring that proper procedures are in place.

As soon as possible, employees who are authorized to come into close contact with the spill should use warning signs or tape to seal off the leak. If the leak occurs indoors, emergency personnel should immediately seal the ventilation ducts and open doors and windows leading to the outdoors to allow the vapor to dissipate.

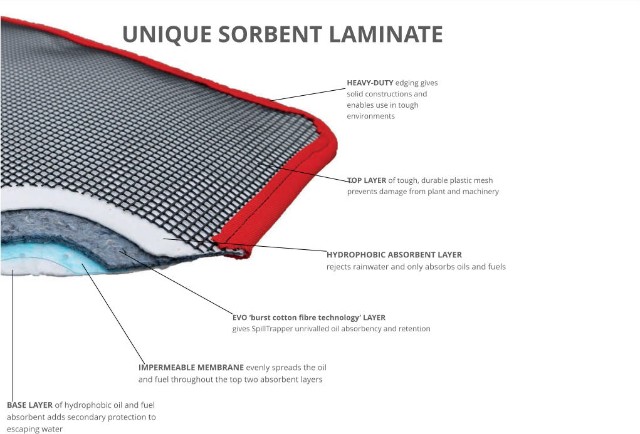

Then, the spill team should place barriers such as absorbents around the spill to prevent it from spreading. Common materials used for this are polyurethane, PVC or absorbent polypropylene socks. Socks can block and absorb dangerous spills and once used should be treated as hazardous waste. On the other hand, you could use a flexible barrier can this only prevent spillage but not absorb the fluid. Sandbags are not designed to absorb harmful substances and must not be used for cleaning. Flood dikes are extremely important to prevent materials from spilling into storm drains or sewers and further polluting the environment.

At this time, HAZMAT technicians should be taking over. The first process is to characterise the leak location by identifying the chemical substance in the leak and then determining the hazard. This characterization is done through the use of direct-reading instruments that provide quick information about environmental conditions. There are a variety of instruments available, including combustible gas monitors, detection tubes, and field instruments. Technicians should also pay attention to open pits and material piles that may be unstable.

Once the characteristics of the scene are determined, the Hazmat Team Leader will determine whether the leak requires special handling, and then order appropriate handling procedures. In most cases, absorbent compounds will be spread on the spill. These compounds are usually granular and absorb the material. They should be inert and therefore cannot react with the chemicals they absorb. Then, add disposable absorbent pads, which are also inert to absorb the remaining material. Then place these pads and compounds in OSHA-approved containers for disposal.

Although this process is routine most of the time, if the material is flammable or close to electricity, special precautions should be taken when shoveling and use a non-sparking shovels and gloves and turning off all electronic equipment for cleaning before use.

Finally, the contaminated material is transported to an approved hazardous waste material facility, where it is processed and reused or rendered harmless, and then sent to a landfill.

After a leak occurs, all relevant personnel must undergo decontamination procedures. Employees pass by the workstation, where their PPE is cleaned and thoroughly washed with water and detergent. This washing liquid is discarded and the worker takes a shower. At this point, the cleaning process is complete.

In the event of a dangerous leak, everyone has a job. Get a thorough understanding of your situation so that you can help your facility, avoid injuries and complete the cleanup effectively.