Testime Technology Ltd (TTL Electronics)

Since 1995 Testime Technology Ltd has provided key RF and Microwave components to markets as diverse as radar systems to satellite communications. From its beginning, the company has also been a supplier of high reliability semiconductors used in the most challenging of environmental settings. This component knowledge is also applied in the ability to provide obsolete or hard to find components especially for high reliability applications.

Our close relationships with suppliers means that we have often been able to offer tailored solutions that exactly match the customer’s requirements.

Our partners have extensive Engineering and testing capabilities for even the most challenging military, avionic and industrial applications. From lead re-termination to improve solderability through to advanced component failure analysis, Testime Technology can call on the the resources to meet your needs.

Filter products and services

-

Component Marking and Labelling

Testime Technology provides a range of services for electronics engineering from Component Marking, Labelling and Sourcing through to complete re-engineering of a device that is no longer available as a standard production item.

Our partners have extensive Engineering and testing capabilities for even the most challenging military, avionic and industrial applications. From lead re-termination to improve solderability through to advanced component failure analysis, Testime Technology can call on the the resources to meet your needs. Capabilities available include the design or redesign of hybrid assemblies for space constrained or avionic applications.

For more information please don’t hesitate to contact us;

Tel: +44 (0)1256 818746

Email: sales@ttlelectronics.co.uk

-

Component Sourcing

Testime Technology provides a range of services for electronics engineering from component sourcing and testing through to complete re-engineering of a device that is no longer available as a standard production item.

Our partners have extensive Engineering and testing capabilities for even the most challenging military, avionic and industrial applications. From lead re-termination to improve solderability through to advanced component failure analysis, Testime Technology can call on the the resources to meet your needs. Capabilities available include the design or redesign of hybrid assemblies for space constrained or avionic applications.

For more information please don’t hesitate to contact us;

Tel: +44 (0)1256 818746

Email: sales@ttlelectronics.co.uk

-

Component Sourcing

Testime Technology Ltd provide Component Sourcing.

-

Component Testing

Testime Technology provides a range of services for electronics engineering from component sourcing and testing through to complete re-engineering of a device that is no longer available as a standard production item.

Our partners have extensive Engineering and testing capabilities for even the most challenging military, avionic and industrial applications. From lead re-termination to improve solderability through to advanced component failure analysis, Testime Technology can call on the the resources to meet your needs. Capabilities available include the design or redesign of hybrid assemblies for space constrained or avionic applications.

For more information please don’t hesitate to contact us;

Tel: +44 (0)1256 818746

Email: sales@ttlelectronics.co.uk

-

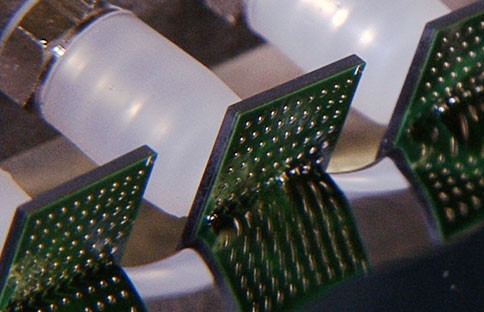

Corfin Modification & Repair

BGA Reballing for Conversion to Tin-Lead or RoHS-Compliance - Flushes all balls and alloy residue on the pads and replaces balls of Sn63Pb37, SAC305, or any other specified alloy.

Trim & Form - Forms and trims straight leads for surface mount placement per the customer's drawing or Corfin Industries can propose a drawing. An RHSD process typically follows this process to coat leads and prevent oxidization.

Re-Conditioning of Bent Leads - Robotic process realigns leads that are bent and scans to verify results.

Lead-Attach to Leadless Chip Carriers - Reduce solder joint stress by attaching J-Shape and L-Shape leads to LCC's using thermocompression bonding.

-

Corfin's BGA Reballing

Corfin’s BGA Reballing process flushes all lead-free balls and alloy residue from the pads and replaces them with Tin-Lead balls. RHSD equipment remove the balls and refinish the pads resulting in 100% pad alloy replacement ensuring the strongest solder joint. The traditional whisker-free SnPb reflow process is not compatible with Pb-free BGA balls. Corfin’s reballing process has undergone extensive qualification testing at independent labs proving that the process is safe and reliable.

Corfin's BGA Reballing Services:

- Conversion to tin-lead

- Conversion to RoHS Compliance

- Ball Attach to LGA, QFN and DFN packages

- LGA Gold Removal and Reballing

-

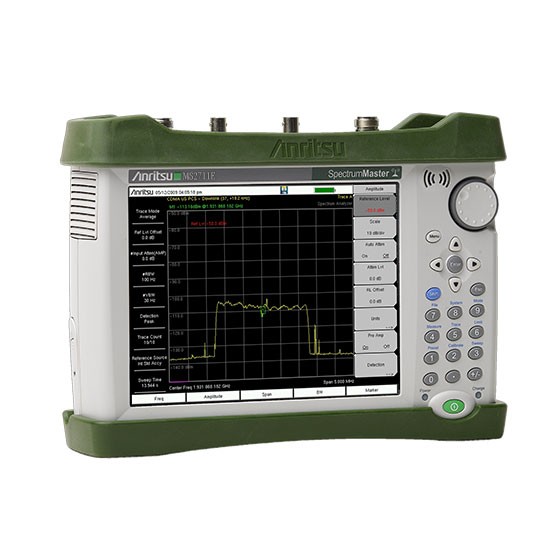

Corfin Testing Services

Corfin’s tight robotic controls has been extensively qualified to provide the confidence of repeatable performance. This confidence avoids the costs for testing beyond visual inspection and the loss of devices for destructive testing. However, there are some devices and critical applications that justify an enhanced level of monitoring. Corfin is ready to satisfy these requirements. Here are some of the testing services available:

- X-Ray Fluroescence Analysis (XRF) - Determines the percentage and thickness of Lead (Pb) and other elements in termination finishes.

- Fine and Gross Leak Testing - Also referred to as Seal Test, these tests verify that the hermetic seal of a component is intact and typically follows Trim and Form and/or RHSD of a glass-sealed device.

- Solderability Testing - Verify termination finishes will readily accept solder during assembly using J-STD-002 test or other military specification.

- Cleanliness Testing - Determines ionic contamination on the part that can cause current leakage between leads.

-

DAT60KU Attenuator

18GHZ DIGITAL ATTENUATOR 60DB -

DAT64F Attenuator

6GHZ FINESTEP ATTENUATOR 64DB -

DAT64H Attenuator

12GHZ 64DB DIGITAL ATTENUATOR