Third Dimension

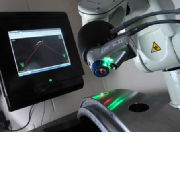

The GapGun is a wireless laser gauge used extensively across the world by major manufacturing companies, primarily in aerospace and automotive markets.

To see the GapGun range and our GapGun experts exhibiting at a tradeshow near you, visit our events calender.

With our extensive list of dedicated distributors, the GapGun is a truly class leading product, with the best ergonomics, repeatability and data handling capabilities in the world.

Click here for our list of worldwide GapGun distributors.

As its name might suggest, the GapGun is designed to measure gaps. But that is just the beginning of its measurement capabilities. The GapGun can measure not just gaps, but shapes and forms such as flush, step, radii, weld profiles, mismatch, seals, scratches, and edge radius to an accuracy of 10µ.