CP Cases Ltd

For over 50 years, CP Cases has been designing and manufacturing an extensive range of bespoke cases and 19” racks. Predominantly for Military, Industrial and Commercial applications.

With many years of expertise in the industry, we are confident we have the perfect formula. The innovation, durability and high-performance materials guarantee that CP Cases is the case provider of choice for mission-critical situations. Many of our products are accredited to MIL-STD-810, rated IP65 and carry NATO stock numbers.

Our West London HQ houses a range of in-house skills including rotomoulding plastics, Aluminium, laminating plywood, HPP, textiles, CNC foam machining, and label & screen printing. We feel at an advantage with everything under one roof; cutting down on lead time and bringing that bespoke attention to detail to our service from start to finish.

An extensive selection of options includes climate control (compressor and thermoelectric air conditioning units), EMC shielding; fire resistance, and anti-static capabilities. We are constantly developing and refining our product range, pioneering the most effective preventative solutions for weather resistance, water ingress, rough handling and severe impact.

-

Why are custom foam inserts for cases so important?

28 June 2021Whatever you’re transporting or storing, you want your equipment or goods in perfect condition. Foam inserts for cases can offer complete protection, whether they’re holding medical, electronic, military or camera equipment, or some other delicate items.

How do they do this? Well, foam inserts for equipment cases have several vital properties. They are:

- Precisely shaped to provide full support to equipment

- Rigid enough to carry objects’ weight

- Soft enough to cushion items against impact

- Designed to avoid reacting with equipment, through discolouration or adhesion, for example

In addition, foam inserts must also look presentable for items that will be showcased in their cases.

How do foam inserts protect equipment?

Simply put, if there’s an impact on a case, the foam inserts come between that impact and the case’s contents. The energy from the impact is dissipated in the foam. Individual objects within the case are also prevented from coming into contact with one another, as each item sits within its own niche, which has been precisely cut out of the foam to hug the item on every side.

As well as guarding against impacts, the foam also protects equipment against prolonged vibration, which can loosen parts and lead to damage.

For added protection against impacts, hard cases are required. They can soak up more powerful impacts, sometimes becoming damaged themselves while leaving the goods inside untouched. When these powerful impacts occur, the foam decelerates the items before they can make contact with the case’s inside surface or, indeed, with each other. The foam then recovers, ready to protect against any further accidents.

Choosing the right foam

If the contents of a case are to be fully protected, selecting the correct density and rigidity of foam is vital. The choice made will depend upon the mass of the contents and how delicate they are.

If there isn’t enough support coming from the foam, the objects inside could crash into the case. Thicker foam allows more room for deceleration after an impact and reduces the peak load on the equipment inside. However, thicker foam will require a larger case.

How are foam inserts made?

To create spaces in foam inserts for individual objects, CNC (computer numerical controlled) machining is often used. It smoothly and precisely cuts the foam to exact specifications, with measurements taken directly from the objects themselves, from scanned data or from 3D data supplied by the items’ manufacturers.

The objects can then travel together, but separated from each other to prevent damage. This has the added benefit of making the items easy to find and identify in their case.

A professional look

Not only do foam inserts in protective cases prevent damage to the contents. They also provide an elegant option for displaying a brand. Different colours and two-tone foam are available, as well as logos and text, helping to showcase a brand’s identity alongside its products.

CP Cases offers expertly crafted foam inserts, which have gone through a rigorous process of precise machine cutting, sculpting and hand-forming. We offer various options for colour, multiple laminations and foam materials, including those with anti-static, conductive and self-extinguishing properties.

If you have any questions about foam insert protection or wish to discuss a bespoke foam design, contact CP Cases on 0208 568 1881 or email info@cpcases.com.

-

IP Ratings & Standards for Enclosures Explained

8 June 2021An IP rating is useful as it defines how well an enclosure protects its contents from outside factors in a specific and precise way, rather than relying on generic or vague terms such as ‘waterproof’ or ‘dustproof’. Testing the enclosures of products is important for safety purposes and to ensure product performance. It also gives buyers and sellers confidence in the safety and functionality of the IP rated product. IP ratings can be seen on everything from Bluetooth speakers to the protective cases for military equipment, but what does the rating actually indicate?

What is an IP rating and how is it broken down?

An IP rating (also called an Ingress Protection or International Protection Rating) is a two-digit grading system that’s given to an enclosure of a mechanical or electrical item to indicate how effectively the device is sealed against the intrusion of foreign bodies such as liquids. IP ratings always carry the same format, for example ‘IP35’ or ‘IP68’.

The IP rating system is actually very simple and easy to interpret. It starts with the letters IP. Then the first digit, ranging from 0 to 6, indicates the level of protection against solids. This includes any solid foreign objects, such as tools or fingers, that could cause damage to any electrical or moving parts within the enclosure. The second digit ranges from 0 to 8 and refers to the level of protection against liquids. This shows protection against various levels of moisture exposure, from the natural elements to full submersion. Essentially, the higher the rating, the more effective the sealing.

If either of these digits is replaced by an X, it means that the enclosure has not been tested or the test is not applicable, not that the item offers no protection from liquids or solids. A rating of 0 in either category indicates no protection.

IP testing

The IP testing process is demanding and is performed under different pressures and temperatures to ensure satisfactory results. Testing for the sealing effectiveness of an enclosure is an important part of the research and development phase of a product. Unsurprisingly, most issues with the sealing effectiveness of enclosures arise with the seam between two parts. For many products, IP testing is not a requirement for all products, but sellers will often ask manufacturers to include an IP rating for their products before they include it in their inventory. There are different standards and methods used to test for the IP rating of a product to different specifications, but every testing system will yield the same standardised IPXX format rating. The method of testing will depend on the manufacturer.

IP ratings for solids

The rating scale for protection from solid particles is usually displayed in an IP rating chart and is as follows:

0 – No protection

1 – Protected against a solid object greater than 50mm, e.g. a hand

2 – Protected against a solid object greater than 12.5mm, e.g. a finger

3 – Protected against a solid object greater than 2.5mm, e.g. a screwdriver

4 – Protected against a solid object greater than 1mm, e.g. a wire

5 – Dust protected, i.e. limited ingress of dust permitted and this will not interfere (2-8 hours)

6 – Dust-tight, i.e. no ingress of dust (2-8 hours)

IP waterproof ratings: IP ratings for liquids

To measure waterproofness, enclosures are subjected to drip, spray, rain, continuous stream, depth and submersion testing. An enclosure’s level of resistance to moisture is rated as follows:

0 – No protection

1 – Protected against vertically falling water drops

2 – Protected against vertically falling water drops when at 15° from its normal position

3 – Protected against water spraying up to 60° on either side

4 – Protected against spraying at any angle

5 – Protected against powerful water jets or heavy seas

6 – Protected against water jets (hosepipe) from any directions

7 – Protected against submersion in water under defined conditions of pressure and time

8 – Protected against continuous submersion in water

Occasionally, an IP rating might include an additional letter at the end of the code, for example, IP24D. This simply gives extra information about the protection against specific materials or hazards provided by the enclosure:

D – Wire

F – Oil resistant

H – High voltage device

M – Device moving during water test

S – Device standing still during water test

W – Weather conditions

If you have any questions about IP ratings or want to learn more about our protective cases, contact CP Cases on 0208 568 1881 or email us at info@cpcases.com.

-

What is Foam CNC Machining?

3 June 2021Foam CNC machining is a type of cutting technology that can be used to cut foam to meet exact specifications, making it ideal for cutting custom foam inserts. The foam inserts used in protective packaging are essential to ensure the safety of its contents. To create the empty spaces for the product to lay in, precise machinery cuts away the excess material from a solid block of foam, leaving behind negative spaces.

Different foam types will serve the exact needs of supporting different products, but precise cutting is always necessary for a product that is properly protected and displayed in a professional manner.

What is a foam CNC machine?

CNC stands for Computer Numerical Controlled, which refers to how a pre-programmed computer software is used to control the tools and machines that cut the foam, rather than manual machinery. Different types of CNC machinery are suited to work different materials, but CNC routers are the most common and are the type used for foam CNC machining.

Foam CNC machines are specifically designed to smoothly and precisely cut 3D shapes out of foam materials, such as polyethylene and polyurethane. CNC foam cutting machines can be used to create packaging, decor elements, props, displays, insulation and much more.

How does foam CNC machining work?

First, Computer-Aided Design (CAD) software is used to create and optimise a design based on the object the foam packaging is intended to hold. Once this design is finalised, Computer-Aided Manufacturing (CAM) software is used to turn the dimensions of the design into detailed numerical instructions for the CNC machine to understand. The file information must also be converted into a language that CNC machines understand. This language is called G-code.

The G-code essentially tells the machine what operations to perform, such as the dimensions and depth of a cut, as well as the toolpath to follow. Once the CNC machine has received the G-code and has been set up with the appropriate router bit and material, it is then time to cut the final product out of foam. Precise mechanisms and sharp blades enable the operator to cut any shape out of the foam, as long as the thickness corresponds to the thickness of the material.

What are the advantages to Foam CNC Machining?

Using a CNC machine is one of the best ways to cut high-density foam and the technology has a number of benefits. Using CNC machine yields highly accurate results with consistent product quality. This makes CNC machining particularly useful in the programming of products with complex shapes. The process can also be easily replicated as the same design or template can be used multiple times over to produce products with the exact same specifications, making it an advantageous technique in cases of mass production.

CNC machines also improve production speed and cost-efficiency. CNC machines operate at incredibly high speeds of over 1500 inches per minute and, unlike with traditional machinery, one operator can run several CNC machines at once. On top of the precision and efficiency advantages, CNC machining is much safer than manually operating machines as the machinery operates behind a safety guard.

Whatever item it is that you’re looking to keep safe or transport safely, it’s important to have a high-quality protective packaging solution you can rely on. CP Cases uses CNC routing to manufacture custom foam inserts that meet exacting project specifications. If you have any questions about our foam engineering, feel free to call a member of our team on 0208 568 1881 or email info@cpcases.com.

-

How to ship high value equipment: A complete guide

11 May 2021At CP Cases we supply specialist protective gear across a huge range of industries, and the one thing that they all have in common is that they use highly specialised, sensitive and fragile equipment. From the medical and defence sectors to the broadcasting industry, only the most precisely designed and robustly constructed protection can ensure the consistent high performance of equipment in all settings.

However, the valuable and fragile nature of this equipment means that moving it around the world becomes a major logistical challenge. Here we explain exactly what you need to know and consider when shipping high-value equipment across the globe.

What can go wrong when shipping high-value equipment?

There are a number of different types of transit damage that can occur when high-value equipment is on the move. As soon as the product leaves your possession and is in the hands of the company shipping it, you need to know that it is sufficiently protected against any of these.

- Shock and impact, even from small bumps, can make highly specialised tools and equipment unusable

- Particular frequencies of vibration may damage sensitive equipment

- Static charges can make highly calibrated instruments unusable

- Any level of moisture, dust or dirt can damage sensitive electronics and may interfere with the circuitry that causes equipment to run effectively

- Extremes of temperature, humidity and changes in atmospheric pressure may all affect the performance of equipment

Having tailor-made protective cases, climate control units and specialised packaging in place can ensure that your equipment is protected from all of the above, completely sealed in its own microclimate.

Understanding the right type of protective casing for your equipment

We manufacture a huge range of protective cases, some of which come in standard sizes but many of which are designed to specification to meet exact requirements. This can make all the difference in keeping your equipment protected.

- 19-inch racks are used across a range of industries including defence and security. They allow for the safe transportation of fragile electronic equipment within checked baggage limits.

- Rugged textile cases can provide tailored padding for unusually shaped equipment, such as surgical tools or engineering gear while maintaining a lightweight

- Flight cases offer robust, heavy-duty protection for extremely fragile equipment like musical gear, made from plywood and strengthened with aluminium and steel

- Lightweight aluminium cases are widely used across the broadcast industry and can protect their contents against even severe impact

- Climate control transit cases can provide all-round protection from harsh weather, dust and dirt for any electronics, with insulation and air conditioning units fitted in order to prevent overheating.

Opting for aluminium casing can be an effective way to keep costs down if you are transporting something long-distance, but this does not necessarily apply for all types of equipment and some may require heavier casing.

Using inner foam to protect your equipment

Foam insert protection is the last line of defence for your equipment if the outside of a case is damaged. Used correctly, it completely isolates the item inside the case, protecting it from a collision with other objects in the same case and insulating it even the smallest vibrations or larger impacts such as that of the case being dropped. These types of outside impacts can damage sensitive equipment beyond repair, so simply placing it inside a case is not enough.

High-quality foam inserts can cope with repeated impact, are rigid enough to fully protect equipment and are soft enough to cushion it. It is also crucial that the foam can be precisely shaped to support every part of the equipment, and that any adverse effect on the equipment such as discolouration is not a possibility.

How to plan for successful shipping of equipment

In addition to the above, there are several practical steps that you can take in order to ensure that equipment is more likely to arrive at its destination in full working order.

- Undertake detailed and clear analysis of the environments that the equipment will pass through and the hazards it may face. How many times will it be handled?

- Assess risks which are specific to each item, whether in transit or otherwise

- Ensure that different types of packaging being used are compatible with one another

- Ensure, as best you can, that all staff involved in handling the equipment at each stage of the chain are aware of how to protect it correctly

- Work only with trusted and reputable transport providers

- Ensure that you have the correct insurance in place

Speak to us today about protecting your equipment

As a renowned worldwide name with over 50 years of experience in the industry, we understand your equipment protection needs and are able to offer unrivalled casing wherever you are shipping it – giving you complete peace of mind. Contact our friendly team by calling 020 8568 1881 and we will be glad to discuss what would best suit your requirements.

-

Customisation – Trusted When it Matters

27 April 2021In today’s market customised products/ services are becoming more and more popular. Spanning across a majority of sectors, there is a growing need to stand out against your competitors and it seems that a custom offering is that lure.

Here at CP Cases Ltd, we pride ourselves on our customisation and more importantly on building that reliable bond between the business and our consumers. From our inception, the stand-out USP for us has been our customisation offering. We now have over 50 years of expertise in manufacturing and design to customer requirements; a badge we wear proudly.

This leaves us in a unique position against our competitors; with the added benefit of our designing and manufacturing all in-house. With customisation comes data, trends and most importantly buying habits which are always robust tools to have in your arsenal. Fitting to customers’ requirements builds that strong communication and helps us as a business not just understand the customer but also the markets they are based in.

Matching innovative design, patented technology and 50 years of expertise stand us in good stead.

We believe with a bespoke order, there is flexibility for the product to evolve over time to match the changing customers’ requirements. That is why we work together with our customers so that any material changes, re-design features, rigidity testing, or any other processes can be reviewed in an instant with custom resolutions.

Customer loyalty is important, especially within the sectors we work in. Products need to be reliable, high-performance and ready to be used within the operation it was made for. Retention of clients helps businesses in many ways, through loyalty, word of mouth and customer promotion. A powerful tool that can open doors to new prospects.

We have a great track record of retained clients within all of the sectors we supply too. We are pleased to have worked and are still working with big names in their market. If you wish to read in more detail some of the exciting clients we have worked with and how we have helped them, take a look through our Case Studies page.

With the markets that we work within, especially Defence, Medical and Broadcast; customisation is a key component. The transportation of a vast range of items spanning from communication software, delegate equipment, to missiles… the list goes on. All of these components need customisation to create that perfect fit for ruggedised protection.

For more information on how we can help to discover any customisable high-performance, portability or storage solutions contact us directly on +44 (0) 20 8568 1881 or email info@cpcases.com

-

Accreditation & Certification in Defence - A Helpful Guide

23 March 2021When working and supplying within the Defence Industry, certain procedures need to be taken into account. Standards need to be met to guarantee customer satisfaction, reliability and efficiency of a company’s products or services.

There are different types of processes that you as a company can go through to create peace of mind for your clients. By having your product line and/or services Accredited to certain standards. Another option is to have your products or processes Certificated. Or go that extra mile and cover the company as a whole; all important factors to take into account when deciding how to position yourself.

Making sure your company is working to the right ISO standards is paramount and needs to be understood and administered properly. But what is the difference? Should your company be accredited or certificated? Why is it so important? We hope that this short guide will answer the confusion.

Accreditation or Certification?

A good start would be to understand the difference between the two. We can all agree these processes are similar but are they both important to have?

It all comes down to who confirms the recognition. Accreditation and Certification are both voluntary processes that provide assurance on particular products, services, processes etc…

Generally speaking, Accreditation is thought of as a higher-level of recognition because the independent (approved) bodies are what are accepted as standard. But both are internationally recognised and have a part to play.

They can come hand in hand as Accreditation is granted for particular actions and can prove a business’s worth. While Certification is granted with written assurance to maintain quality and reassurance of the company as a whole or individual products/ services.

The Importance of Accreditation & Certification

The importance of your company being Accredited and Certificated is key to building your brand in a positive way and creating customer loyalty; which in-turn helps with retention and positive word of mouth.

There are many other benefits of a company complying with standards; including your products and efforts being internationally recognised. This helps to increase productivity within the company but also gives your customers the guarantee that they are working with an audited company.

Renowned standards include ISO 27001 (Information Security), ISO 22301 (Business Continuity), ISO 14401 (Environmental), and most popular and also the standards that CP Cases adhere too - ISO 9001 (Quality Management).

Conforming to Military Standards and IP Ratings

In an industry where everything needs to work at critical times without delay, it is important to be able to evaluate performance-based standards before committing to purchase. You need a brand that you can trust that achieve and maintain specific standards every time.

Product engineering and manufacturing need to withstand rigorous testing of Transit Drop, Blowing Rain and Sand, Fungus, Hot and Cold, Sunlight, and Ingress Protection (IP). This helps to guarantee the equipment will perform how it is meant too when used in the field.

Many of our products are accredited to MIL-STD-810 and rated IP making them essential equipment for Defence and military applications. This includes a lot of our flagship products including Amazon Cases, Amazon Racks and ERack.

We hope this guide has given you more of an understanding of what standards/ procedures need to be accounted for when working in the Defence sector. Why not take a look at our accredited products range or contact our team for more information - info@cpcase.com or call +44 (0) 208 568 1881

-

The importance of face-to-face exhibitions and their position in the market

9 March 2021The year of 2020 will go down in the history books, not only for the devastation of the pandemic but the vast number of processes to quickly adapt to the everchanging challenging environment. It was a year of reflection, the digital revolution, a year of remote working.

Businesses had queried whether office space was worth the rent when most, if not all of their employees were working from home. Or, the number of advantages of virtual audiences for a whole host of events had been questioned, changing perspectives and paving the way to a new normal. But if there is one thing that has been truly missed… face-to-face exhibitions and trade shows are at the top of that list.

The absence of face-to-face exhibitions

Exhibitions are a powerful platform for businesses throughout a number of different sectors. It is a chance to come together with similar professionals and share information, promote your business and liaise and build communication with potential prospects.

The UFI (The Global Association of the Exhibition Industry) website identifies there are around 32,000 exhibitions per year globally. With this includes 4.5 million exhibiting businesses and over 303 million attracted visitors per year, with a combined spend of over £104 billion. That is a major industry that is vital to the economy.

Exhibitions have kept with the curve and moved to virtual experiences due to the pandemic. While there has been a number of positives from this, including being able to attend from your living room, reduced travel cost and less strain on the environment – exhibitions haven’t had the same positive experience that they are used too.

The importance of face-to-face

If 2020 has highlighted anything, it would be the importance of face-to-face communication at exhibitions. A physical event brings business and consumer together on a different level. It’s more informal and you can draw from prospects reactions. Face-to-face relations create a lasting relationship and a more hands-on solution with your consumers – which in turn converts to higher customer retention.

Another missed opportunity for face-to-face exhibitions is the opportunity to understand your competitors. The chance to collect important research of consumer reactions, working methods, marketing inspiration etc… of the competing businesses. This gives you a clear view of where you are doing well and the areas you may need to improve.

If you find your business/ service more of an ‘in the moment’ feature; you desire that traffic of people walking past your stall and thinking ‘Oh yeah, I need that!’. Face-to-face gives you this opportunity which was hard to convert to a virtual experience; we found out this the hard way at DPRTE’s 2020 event back in September.

Face-to-face gives exhibitors and visitors… professionals and amateurs the chance to learnt new information, market trends, draw from other people’s stories and liaise with likeminded people in their chosen sectors. That time and information are invaluable. As much you try to convert this over to a virtual experience; nothing beats the paybacks you get from being there in person.

The current state

The current climate is still in a risky state at the moment but the success of the vaccine rollout has brought new hope as the way out of this pandemic. It is still hard to plan ahead or know what is going to happen but we are hoping there will be a return to face-to-face exhibitions still this year; even if it is more towards the end of the year.

We know many businesses will be in the same position hoping for their steady return. Face-to-face exhibitions are a vital part of a lot of industries; especially in manufacturing as it is a way of showcasing products to a new network of prospects.

If you have any questions about the products that we hope to display in exhibitions this year you can call a member of our friendly team on +44 (0) 208 568 1881 or email info@cpcases.com

-

The 1-year milestone for our UK Sales Engineer

3 December 2020CP Cases has a long-standing tradition of making high quality ruggedised transportable cases; with trading starting back in 1971. Our products range from off the shelf items right through to completely customised cases which are used to transport a vast range of items. The experience learnt from the varied products we have designed gives us a huge wealth of knowledge for us to help find the correct case solutions for you.

That knowledge is an important part of working for CP Cases, which is why it is always a pleasure when we can celebrate an employee’s milestone with the company. Our UK Sales Engineer Stuart Watson has now been working with us for a year (how time flies).

Stuarts background

Originally from a motorsport background, Stuart has a huge range of work experience behind him that he has adapted and grown in his 1st year in the role. His responsibilities centre around focusing on our UK sales and working with our customers to help them find the right solution and fit to their requirements.

Covering a large range of complex products from rucksacks for potability within the communication industry, to Rotomoulded plastic cases for missiles within the Defence and Aerospace sectors. Aluminium 19” racks for offshore research projects, to wooden cases that ship medical robots around the world. Stuart has expanded and developed his skillset and demonstrated a real passion for what he does.

Will all of the uncertainty of this year and the absence of face-to-face, Stuart has worked around the clock to keep our prospect lines warm and kept building those needed relationships with new leads and existing clients.

A few works from Stuart on his first year at the company:

“It is great to come and work in a company with such a strong and interesting history, with such varied products, technology and markets. It keeps everyday interesting.”

We are confident that Stuart will continue to grow within his role at CP Cases, and we are excited to see what other experiences and knowledge he can bring in the years to follow.

A note from our Commercial Director, Fiona Haggerty:

“Using a combination of CP’s 50 years’ experience and his own technical experience Stuart has worked hard to understand our customer’s needs.

We look forward to working with Stuart over the next 12 months and beyond when we expect to grow and sustain our place in the UK market.”

Some of you may have spoken to Stuart already and if not, why not give him a call. Find out more about how he can help with any technical queries or inquiries you may have.

Call: 0208 8568 1881 or email: swatson@cpcases.com

-

Introducing the new ERV3

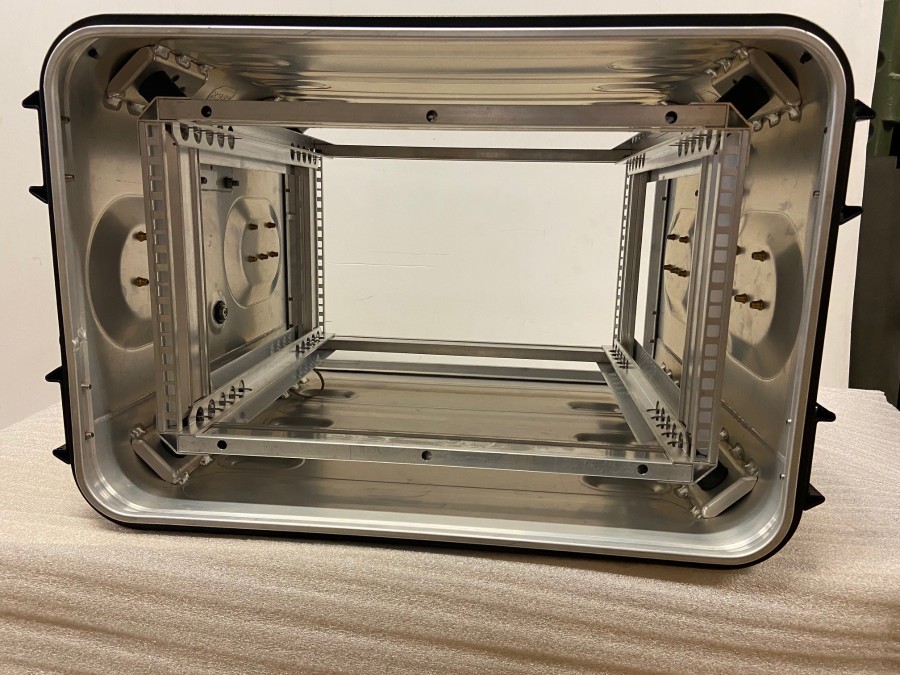

15 October 2020Our reliable and innovative ERack design has been a customer essential since its inception in 1995. In regular use by customers worldwide for the transportation, storage and protection of 19” rack-mount electronics. Our experienced product engineers have now developed many enhancements but retaining the same proven functionalities of the ERack design. Introducing the third generation of ERack (ERV3).

Lightweight rugged enclosure

You know the phrase 'if it's not broken, don't fix it'... well our ERV2 design was a hard act to follow, never mind improve on - but we know we have succeeded encapsulating all of the ERV3's predecessors’ best design features. With a lightweight rugged enclose as our starting point and matching the weight and strength of the ERV2, the new body design features large radiused edges and additional choices on venting and sunshade options.

The lids are press formed to give increased rigidity and stiffness, and precision formed dispensed with all welding processes; thereby eliminating potential leak paths. A choice of recessed rotary latches or surface mounted side latches remain available, together with options on connector panels. ERV3 lids can also accommodate customer branding, by either debossing or screen printing.

Hollow section extruded aluminium is CNC formed for the male and female profiles that are bonded to the body and lid to ensure a perfect ‘mate’. This provides the silicon gasket with a repeatable compression set forming the weatherproof protection for the interior of the EVR3 which are MIL-STD 810G and IP65 accredited.

New rotary latch design

The newly designed rotary latch is simple and comfortable to use – even with gloved hands. It provides a simple functional closure that resists shock and vibration and is calibrated to provide consistent compression for the weather gasket to seal perfectly.

Stacking Rubber Buffers and improved AV performance

A new feature on ERV3 is the option for large external self-stacking buffers. The 80 shore hardness TPEV rubber buffers provide additional protection in rough transit conditions through the non-slip positive stacking feature.

A new elastomeric AVM design has improved elastomeric excursion. This enhances the ERV3’s protection against shock and vibration.

Structural Bonding

ERV3 employs aerospace high-performance bonding technology, with two-part acrylic adhesives that offer excellent shear, peel, and impact performance. These toughened products provide improved adhesion to plastics and metals, featuring a fast cure rate, providing structural strength in minutes. Similar high-performance engineering has been used in other applications such as aeroplane manufacture and F1. (hyperlink case studies)

19” Shock-mounted Chassis

The ERV3 enclosures include the pioneering lightweight CV2 high tensile extruded 19" chassis. This gives the design infrastructure torsional rigidity and stiffness when the Rack is under severe loads. The Chassis is resistant to shock, drop, impact and vibration. CV2 chassis have been separately tested and accredited to MIL-STD-810G, and are iridited (surface coat conversion) when incorporated into EMC applications.

EMC Shielding

With the growing requirement for secure communications and protection from cyberattack, electromagnetic screening is often required to help prevent system hacks when in high-risk environments. Specialist conductive gaskets, use of wire mesh braid, embedded wire and Faraday cage features can be incorporated into the ERV3's design. This offers the customer various levels of EMC screening.

ERack products that incorporate EMC shielding are fitted with appropriate venting and pressure relief systems that perform to prerequisite emission Db levels.

It’s durability, functionality and lightweight monocoque construction makes the new ERack design the perfect ruggedised 19" rack enclosure for defence and commercial applications.

-

Reducing lead time with our in-house Printing Machine

15 October 2020The need for a quick turnaround in manufacturing is becoming more and more prevalent. Companies are continuing to look for innovate ways to continue practical and cost-effective production lines; along with reducing lead time in whatever way they can. An industry that continually requires rapid turnaround is Broadcasting and Live Events; an industry that CP Cases have a steeped history working in.

History in Broadcast and live event

CP Cases has its roots in the live events industry initially producing flight cases for the renowned touring rock bands of the 1970s.

Bands such as Led Zeppelin and Pink Floyd. World-famous artists such as Elton John relied on CP Cases to transport their equipment from the tour bus to the stage. Taking incredible impact on tour after tour, some of these early sound equipment cases are still in use today. Some 40 years later which highlights just how durable these cases are.

Our designs have evolved to accommodate the ever more sophisticated requirements of today’s live events. From portable studios and production units. Outside broadcast units. Electronic equipment cases. Lighting and sound consoles. Even electronics racking for all your event audio needs - the choice is clear.

CP Cases provides a wide variety of products for the broadcast and professional media market. From camera & filter cases, through to outdoor broadcast. We even develop mobile and portable solutions for emergency reporting.

Camera and filter cases are designed using rugged textiles, aluminium or polyethylene subject to the customer requirements. For outdoor broadcast, we have a whole range of camera rain covers that are made for particular makes and models. But we more often than not, we use customisation.

The Printing Machine

For more than 25 years we have worked with Broadcast camera manufacturers to develop protection for their equipment kits. Our range of outside broadcast camera covers enable us to respond quickly to the requirements for camera weather protection. We have designed the rain covers to meet the extremely high expectations that many OB kit managers; focusing on the perfect mix of quality, availability, and value for money.

We keep stock off 100’s of metres of materials so that colour options are readily available. This helps us with a smooth transition when corporate messaging needs to be compiled with. We also have the capability to apply full-colour logos. Managing this in-house dramatically reduced the lead time as delays in supplies is never experienced.

We understand the need for urgency across all industries; especially within the Military and Security sectors. So reducing the lead time in whatever way you can is paramount. Bringing the printing in-house and keeping stock of 100's of materials helps cut valuable time off manufacturing. This has helped us keep to tight deadlines and keep customer satisfaction.

-

London to Brighton Bike ride Training Session 2

8 February 2017Round two of our training for the London to Brighton bike ride took place on Sunday 10th April and took us through Richmond Park, Hampton Court and Bushy Park. Most surprising to all of us was the ease by which we found ourselves covering some 20+ miles, very re-assuring for the 54 mile ride ahead of us.

That said having had a pretty gentle start we were very quickly confronted by the infamous Nightingale Lane – a short road that takes you from river height to the top of Richmond hill. It gave us novices the most challenging introduction to Richmond Park. I’ve since discovered that the gradient, at its best (!), is 16.3% – it’s only a 2,000 metre road but by the time you reach the top your heart is pounding against your chest, your legs are seizing up, steel like, and control of your bike has somewhat left your natural senses. Suffice to say, we rested at the top of the hill for a while and enjoyed the view following the Thames as it snaked its way to Hampton Court!

Incidentally, there is a men’s and woman’s leader board for the Nightingale Lane ascent, needless to say, in typical modesty, I won’t be revealing the team’s times and efforts.

There’s good reason why hill training will shortly become part of our preparation as we will encounter the notorious Ditching Beacon between miles 46 and 47 on our way to Brighton. With a distance of 1.5km and gradients ranging from 2-16% it represents a huge challenge. Some, like Nightingale Lane, have already conquered it with great distinction. Round three of our training will be sure to provide a little more intensity.

However, we continued on our bike ride through Kingston and along the towpath to Hampton Court where we indulged in the traditional British style of tea and biscuits. The Spring weather had certainly made the roads more busy but we safely negotiated a couple of major junctions to make our way to and through the beautiful Bushy Park before returning back to base in Isleworth.

Round three is now in the diary, Sunday 15th May, when we plan two laps of Richmond Park. For information about the London to Brighton bike ride and the cause it supports please visit here.

-

ROHDE & SCHWARZ

19 October 2016Super lightweight case and ease of portability

Rohde & Schwarz recently announced the release of their Benchmarker II Go, a highly scalable and flexible benchmarking solution for mobile network system testing. The product is a lightweight and robust transport case holding up to eight commercially available smart phones, laptop, power supply and associated cabling. Benchmarker II Go has been designed to support the telecommunications market, mobile operators and service providers allowing testing whilst on the move – nationally and internationally.

The product was specifically created for ad hoc measurement campaigns therefore it had to be a contained unit, easily transportable and lightweight. Given that the measurement campaigns are national, international and on the move the product design had to account for a number of key applications.

CP Cases were approached to design the case to help give Rohde & Schwarz a go to market strategy in support of Benchmarker II Go.

CP Cases came into play for a number of key reasons.

- Firstly the case; because it’s on the move, nationally and internationally, the client needed a case that was easily portable and would meet IATA International Air Transport Association) guidelines.

- Secondly, the weight; given this is typically a one man operation the case construction and design had to be super lightweight and offer ease of portability.

- Thirdly, strength; sensitive equipment on the move needs to be operational on site – the case needs to be strong and robust.

-

CAMERA CORPS

18 October 2016Cutting edge technology that captures unique live TV coverage.

Camera Corps are designers and manufacturers of speciality remote camera systems and has been appointed for many prestigious and high profile events and productions including entertainment shows and international sporting events. Their products bring the genuine “wow” factor to live coverage and slow motion replays from unusual and challenging positions and environments.

CP Cases were approached by Camera Corp to design camera covers to protect their camera systems when in operation at some of the leading aquatic events – given the camera systems were remotely controlled and inverted to capture unique footage, we were set some unusual and difficult challenges.

Camera Corps speciality camera systems are the hallmark of performance therefore we needed to ensure our solution was a superior match and exceeded expectations ensuring the viewing public’s entertainment was not disrupted.

The design had to account for complex and simultaneous movements; from a complete 360° rotation to a vertical y axis movement, as the camera followed its subjects through dives and turns. Neither could camera cables become entangled with the cover nor could it be allowed to slip and cover the lens, thereby snagging the camera or blocking vision.

-

Camera Rain Covers for OB

10 October 2016In our 22 consecutive year exhibiting at IBC, CP Cases announce the availability of a brand new solution for weather protection for the very latest generation of 4K OB cameras and lenses.

Developed this year, specifically for 4K coverage of live sporting and music events throughout Europe, this range of camera covers brings together the very latest advances in textile manufacturing technology with designs that provide camera operators free and ergonomic access to essential controls and connections.

New manufacturing methods at CP Cases, utilise the latest seam sealing technology. Most commonly used in the assembly of military specification garments and shelters, CP’s new machinery ensures that seams of these new generation covers are continuously and imperviously sealed to protect against the very worst of weather.

Working with senior camera operators and equipment & logistics managers, these covers provide uncompromising levels of weather protection and enable freedom of access to all the cameras essentials.

Zipped access slots along the sides are covered with a weather proofing eye-lid flap to enable the attachment of auxiliary boom mics and increase ventilation when working for long periods in hot, humid and breeze-less venues. Clear acrylic viewing windows and draw-cord sealing pan-bar sleeves provide near noiseless operation.

For those venues where spectator sightlines must be preserved, mounting viewfinders as low down as possible has often been a challenge. Providing weather protection for these ‘unconventional’ camera set-ups, whilst giving full operator access, is now made so much simpler.

Separate viewfinder covers are provided with the main camera and lens covers and allow the set-up to be rigged with the viewfinder fixed to the left-side, right-side or even top dead centre.

With manufacturing and stock holding at our UK headquarters near London, CP’s capabilities in customising our core products with corporate branding and specific colours schemes is applicable to this new product line also.

Produced for camera configurations using Sony, Grass Valley, Panasonic and Ikegami cameras, with Canon Digisuper or Fujinon 4K lenses. Available also to suit cameras with HJ40 telephoto EFP type lenses and HJ14/22 ENG type lenses, either upon tripod or shoulder-mount.

CP Cases New Generation Weather Covers have been used extensively this year at many OB events, ATP tour, F1, Wimbledon, Farnborough Airshow, Glastonbury, Americas Cup, UEFA EURO 2016, Rio Olympics and Griffin Park.

-

EASYGLIDE

14 September 2016EASYGLIDE: Slide-out Chassis = Less Headaches

Let’s say your 19” rack-mount electronics have cables, buttons or switches that must be accessed regularly, or you want to be able to move the entire chassis to a workbench to have all-around access to your gear, or you like the idea of being able to easily swap electronics from Rack A to Rack B. Here’s a great solution – CP Cases’ EasyGlide Option.

Available on most sizes of our transit cases, including our Amazon rotomolded polyethylene racks, as well as our welded aluminum ERacks, this accessory provides increased convenience and reduced downtime related to the maintenance and replacement of your rack-mount electronics. This innovative slide-out 19” chassis includes top, bottom and side supports, Teflon-coated slides and a self-anchoring internal frame system.

-

London to Brighton bike ride The Event

27 June 2016London to Brighton bike ride – The Heart-throbs

So the day finally arrived… were we ready? Had the training done its job? Would we have an incident free journey? What was the weather going to be like!?

Sunday 19th June we met at CP Cases at 5.45am, brimming with apprehension and nerves – but there was excitement and anticipation to get the adrenaline going. Some of us had done the ride multiple times and for others it was the first. Bikes were loaded into the van and we set off to the starting point at Clapham Common – our start time was 7.00am. The weather was on our side, dry but above all hardly a breeze.

Before we knew it we were off, the organisation was first class. We weaved our way through London’s suburbs and in no time began to break up – it was impossible to stick together the sheer number of cyclists and differing game plans took toll of that immediately. The early ride was ‘easy’ pulled along by enthusiasm, energy and co-operation with fellow riders you’d never met before.

Time and the early miles went quickly, the suburbs gradually turned to countryside and then it got tough, very tough…and quickly. Now, the wise man said that for every uphill there is a downhill…that wore thin after a very short while as every downhill meant there was also an uphill…the early hills were tough, some of us walked them, some of us cycled them but they sapped the energy from our legs.

Early and welcome breaks from some, others continued.

A notable milestone was seeing aircraft overhead, a strange relief as it signified we’d journeyed as far as Gatwick, reassuringly over half way now…but the hills and now even slight inclines were relentless. Legs were seizing and almost cramping as the ride continued. Thanks to the onlookers and staff at the refreshment points for their applause and motivation – many locals had set up chairs and tables at the front of their houses to cheer us along, with an incentive of tea and biscuits to stop and relax along the way.

The ride continued, did I say legs were seizing and cramps developing and then a nightmare at 40 miles, a rest. Unhinging ourselves from our bikes and treading with trepidation until we felt walking was normal again – co-ordination was somewhat lost at this point. Oh but the nightmare, 12 miles to the finish line but Ditchling Beacon ahead of us… a one mile uphill climb of 143 metres with gradients ranging from 9%-16%.

Ditchling Beacon is the toughest of encounters. You’ve been on your bike for the best part of 4 hours, some of us longer, you’ve already tackled several notable hill climbs and covered 46 miles by the time to get to the bottom of this particular nemesis. But people did it, and so did several from our group…kudos to them, fantastic energy and commitment. As you reached the top you were reminded that this was it…all downhill, at last.

Freewheeling at this point is not for the faint hearted, so some adopted a more cautious approach. A couple more miles along a flat cycle track and then paradise…Brighton Pier and finally we get a mention as we cross the finish line. Relief and huge satisfaction ensues.

Would we do it again? Now is not the time to ask, the aches and bruising is still raw!

But here’s the really important stuff. The Heartthrobes managed to raise over £1,000 in support of British Heart Foundation. For more information about the charity please visit. https://www.bhf.org.uk/

-

VIDEO SURVEILLANCE SYSTEM FOR THE ITALIAN ARMY

11 May 2016

The Italian Army Aviation has recently received the first CCTV video surveillance system, field deployable kit. The system is aimed to provide video surveillance and anti-intrusion to temporary structures like tents, containers, etc. during out of area operations. It is lightweight and designed for the maximum degree of mobility and transportability, also via airlift. -

Ruggedised Case that meets IATA guidelines

15 April 2016Most airlines follow IATA (International Air Transport Association) guidelines regarding the size limit for standard checked baggage (L+W+H = 158cm max.). Our engineers studied this requirement and developed a ruggedised case to take advantage of the largest space allowed.

We’re now announcing our new Amazon (rotomolded polyethylene) case – Model AC7545-3107.

As with all of our Amazon products, this case is exceptionally durable, waterproof, weather-resistant, corrosion-proof, shock and vibration-resistant and certified to MIL STD 810F. Other highlights:

- Hinged or removable lid

- Recessed wheels for portability

- Soft-grip handles

- Stainless steel hardware

- Various colors (UV-stabilized)

Custom foam inserts also available

-

STEVE MITCHELL, STEADICAM OWNER

14 March 2016Steve Mitchell, a Steadicam Owner and Operator, contacted CP Cases to provide a long term solution to protect his camera equipment during international transit and storage – in essence his income. Steve entrusted the CP Cases sales team and designers to develop a solution that required bespoke specifications and met exacting standards. Whilst CP Cases can bring you the story, we feel it’s better coming from Steve.

Background

Being a Steadicam Owner/Operator for many years, one of the most important things for me is keeping the kit safe from potential damage during all types of transport and transit. I travel a lot with the kit frequently using airlines, which although the flight cases are marked as fragile once out of view it is anyone’s guess how it is handled. Making sure the kit is properly packed therefore is of paramount importance.

Having used loose foam packing for years the kit did move around within the cases during heavy transport situations and it could be only a matter of time before damage occurred, so we decided to approach CP Cases about having custom foam insert made.

The Project

My reasons for choosing CP Cases, I work on a regular basis with Outside Broadcast and Equipment hire companies. CP Cases have an excellent reputation within the industry and I see them at first hand and have always been impressed with their high standards.

The whole process of design, manufacture and delivery was A1 from start to finish. Nothing was too much trouble and the level of customer service was excellent. I must admit to being a bit OCD when it comes attention to detail and CP Cases delivered my foam insert which exceeded my expectations.

-

London to Brighton Bike Ride Training Session 1

14 March 2016Our first training session this weekend, it has to be said, was very kind. Having had the date in my diary for over a month we couldn’t have asked for a more perfect day. Although chilly and a slight bite in the air there was beautiful sunshine and a very gentle breeze, just what the doctor ordered given we were just about to set out on a 35+ mile bike ride.

We started in Isleworth, leaving CP Cases’ offices and taking the A4 (Old Bath Road) to Windsor via Colnbrook, Datchet and Eton. A few photos on Eton Bridge were quickly followed by more outside Windsor Castle….I never thought I hear myself say this but whoever thought of bringing the selfie-stick, genius!

The ride in Windsor Great Park was very smooth, easy under foot so to speak, and probably made easier by taking in so much of the natural beauty and vistas. We had a tea break, shared anecdotal conversation with fellow cyclists which revealed some had greater passion than others demonstrated by the investments made in their wheels – more than enough money spent to buy a good quality car.

As the sun got higher the warmer we felt which was matched by the satisfaction of the ride so far and spirit and friendship evident in the team, which grew more and more as we piled on the miles.

Leaving Windsor Great Park and heading back home on the A30 could have been a bit of a let down but it wasn’t. Despite cycling into a slight headwind we all worked with each other, checking on our whereabouts as we made our way safely back home.

So where next? Richmond Park, Box Hill and Canary Wharf are venues suggested to far. If you have any ideas please let us know just bear in mind our starting point is West London.

Above all that its about the cause and the team’s ambition to raise money in support of British Heart Foundation. If you’d like to know more about the London to Brighton Bike Ride you can get full details from the website here.

-

ARION1

13 January 2016Engineered by the University of Liverpool Velocipede Team (ULV Team), a team of sixteen Master’s Degree Engineering students designed and built ARION1, a human powered bicycle, which has broken the British Land Speed Record. This remarkable achievement took place in September 2015 at a location called Battle Mountain in the Nevada Desert. Whilst competing with several other international teams for the world land speed record, the ULV Team broke the existing British Land Speed record by 8mph setting a new record of 83 mph.

The time trial extends over 5 miles but it is only the final 200 metres where the speed is measured. The cyclist has to skilfully build up speed and momentum to reach optimum performance with precise timing. Vehicles are not allowed in front of the bicycle, punching a hole into the oncoming air and turbulence – it is about design, strength, endurance and skill.

The ULV Team, which was established in 2013, is the first British University to attempt the land speed record and their success has served only to fuel their appetite to further their achievement. In 2016 they will be competing with female and male cyclists in ARION2.

-

ONEBILLION

11 January 2016onebillion is a non-profit organisation that provides literacy and numeracy teaching to under privileged children in some of the remotest and deprived parts of the world including locations in Malawi, Uganda and India. The organisation develops English and Maths apps for 3-6 year olds that cover the whole curriculum – onebillion’s aim, and the clue is in the title, is to bring education to one billion marginalised children.

The Project

To fulfil their aim onebillion has set up what they call ‘oneclass’ learning centres where local teachers teach the entire Maths curriculum to young children in their own language (the Maths app is already available in over 50 languages). Pupils are monitored via the internet and so far it has been proven that what used to take 18 months to learn is now accomplished in just 6 weeks, these results along with the independent research undertaken by the University of Nottingham are helping fuel the project.

To enable teachers to share material with every child in the class they needed a self-contained, secure solar-powered projection solution. The end product included the projector, a tablet, a media streaming device to view films from the internet and other sources, speakers, long life battery and all associated cables.

The Project

Because the oneclass learning centres are in some of the most remote regions in the world they have faced some huge challenges; lack of electricity, dark classrooms, availability of text books, class sizes (up to 300 pupils), transport and communications.

onebillion required a single contained device, a protective and easily portable case, allowing the classroom teacher to use the app and project onto a classroom wall. The case needed to contain all the equipment safely and securely – weight, protection and durability were key to the issues that needed to be accounted for during the design process and product development planning.