Cross and Morse

Here at Cross and Morse, we are established manufacturers and distributors of a wide range of mechanical transmission products. Our extensive manufacturing capability gives us the ability to turn, gear cut, grind, keyway, drill and tap, broach, mill, hone, shot blast, induction harden teeth and chemical black. Expert engineering and technical support is available our drawing office use the latest Autodesk® Inventor™ software . At Cross and Morse, we utilise modern CNC equipment to maintain our high quality of service. We hold a large stock of Power Transmission components which gives us a unique position of being both a stockist and a manufacturer.

Filter products and services

-

GF32 Polymer Sleeve Gear Coupling

For all your polymer sleeve gear couplings requirements, the specialists at Cross & Morse will handle everything. We supply from the exceptional GF range of polymer sleeve gear couplings, including the GF32 specification. To find out more, visit our website.Request a Quote Supplied by Cross and Morse -

GF38 Polymer Sleeve Gear Coupling

If you're looking to acquire high-quality polymer sleeve gear couplings, the specialists at Cross & Morse will provide you with an exceptional service. Our comprehensive range includes options from the brilliant GF range, including the GF38 polymer sleeve gear coupling. Visit our website to find out more.Request a Quote Supplied by Cross and Morse -

GF42 Polymer Sleeve Gear Coupling

At Cross & Morse, we offer an exceptional range of medium to high-speed polymer sleeve gear couplings, type GF. This includes the GF42 polymer sleeve gear coupling, often used for the connection of hydraulic pumps, among other uses. For more information, visit our website.Request a Quote Supplied by Cross and Morse -

GF48 Polymer Sleeve Gear Coupling

If you're looking to acquire high-quality polymer sleeve gear couplings, speak to the specialists at Cross & Morse. Our service covers an extensive range of GF polymer sleeve gear couplings, including the GF48 specification, for agricultural and exposed machinery, among other uses. For more information, visit our website.Request a Quote Supplied by Cross and Morse -

GF55 Polymer Sleeve Gear Coupling

For high-quality polymer sleeve gear couplings, the specialists at Cross & Morse offer an exceptional service, which includes the GF24 model. These couplings are suitable for a range of uses, including:- Within the food industry

- For the connection of hydraulic pumps

- For agricultural and exposed machinery

Request a Quote Supplied by Cross and Morse -

GF65 Polymer Sleeve Gear Coupling

At Cross & Morse, our highly professional, reliable service includes the provision of a wide range of polymer sleeve gear couplings, such as the GF28 polymer sleeve gear coupling. This coupling offers a maximum speed of 8000rpm and up to 16.1kW power capacity with its three selectable shaft speeds. Visit our website for more information.Request a Quote Supplied by Cross and Morse -

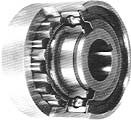

Gold Mounted Ball Bearings

Our sealmaster gold mounted ball bearings are an excellent ball bearing system. They are provided with a wide outer insert bearing and a metal retainer. The steel insert is treated in a black oxide and features a lock pin and dimple system which allows for lubrication of the bearing and helps to prevent the outer ring rotating. Find out if this is the right type of ball bearing system for your needs by contacting Cross and Morse today. You can call our team on 0121 360 0155, or send us an email enquiry to sales@crossmorse.com. Alternatively view our product range and catalogues online at Cross and Morse.Request a Quote Supplied by Cross and Morse -

HT Sprag Clutch

HT Sprag Clutches are designed for end of shaft applications, being retained on the shaft by a deep groove ball bearing with snap ring in outer race locating in recess dia. The outer race of the clutch is tapped for attaching sprocket, gear or ratchet arm Intended primarily for indexing applications, the clutches can also be used for backstop and overrun applications providing the inner race is overrunning.Request a Quote Supplied by Cross and Morse -

H-V and SC Inverted Tooth Chains

Morse H-V Chains provide the designer with a new concept for the transmission of high torques with high shaft speeds. Smooth running drives, with low noise level, transmit up to 4000 kW with shaft speeds up to 12,000 rpm. Proved in a wide range of applications from Automotive Transmissions, to flood control pumps. H-V Chain offers many design advantages over gears, roller chain or timing belt drives.Request a Quote Supplied by Cross and Morse -

Inverted Tooth Chain

Our inverted tooth chains enable your engineers and designers to use different and new concepts for transmitting higher shaft speeds as well as higher torques through their machinery. They are smoother running drives and have a lower level of noise, transmitting up to 4,000 kW. Operations shaft speeds can be up to 12,000 rpm. They are commonly used in applications as diverse as automotive transmissions, pumps and are more flexible in operating than roller chain or a drive belt. Learn more about inverted tooth chain, or place an order by calling us today on 0121 360 0155. You can also see more about our products at our website, or simply pop us an email to sales@crossmorse.com.Request a Quote Supplied by Cross and Morse