Curtiss-Wright Surface Technologies

Curtiss-Wright Surface Technologies (CWST) provides high quality surface treatments which will improve the life and performance of critical components through its global network of over 70 operating divisions and specialist onsite teams. Our surface treatments have been successfully used by OEM’s in major industries such as aerospace, automotive, oil & gas and power generation for many years.

Metal Improvement Company (Newbury Division) offer quality metallurgical solutions to improve the performance of metal. With advanced technology, these improvements can be integrated into products when required and can dramatically enhance lifetimes improve fatigue strength, precision shaping, selective hardness and surface finish.

At Metal Improvement Company (Newbury Division), we deliver our innovative enhancements to our customers and help to create new state of the art products. We offer laser peening, peen forming, controlled shot peening, superfinishing and solid film lubricant coatings.

We are located in the UK with divisions in Evesham, Earby, Sunderland, Newbury, Derby, and Chester.

Filter products and services

-

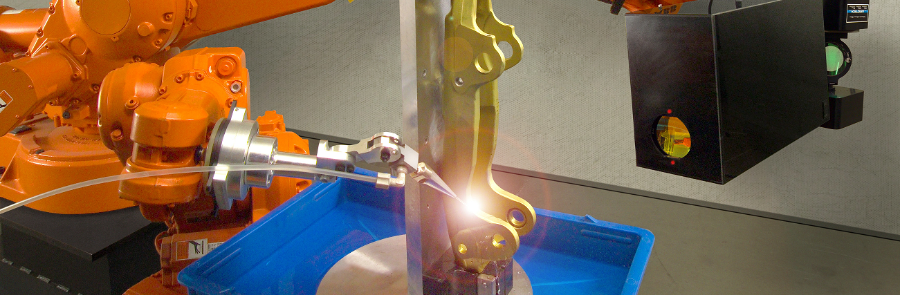

Engineered Coating Services

The correct coating system will improve part wear life and reduce maintenance costs. Protecting against environmental damage and corrosion. We can also develop coatings for new applications.Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Everlube Coatings

Everlube products fall into the dry film lubricant category. They provide low frictional resistance between two mating parts, they are generally used on fasteners, springs, aerospace hydraulic fittings, valve components and oil components.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Exhaust Thermal Spray Coating

Curtiss Wright's thermal spray coating provides excellent protection for exhausts. Our thermal spray coating will protect exhausts from heat and general wear therefore reducing maintenance on parts.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Failure Analysis

When equipment fails or isn't performing as it should it is vital to obtain accurate and quick result to discover the root of the problem.

We have performed thousands of root cause analyses building to our experience on a wide range of failure modes, materials and industries.

We are able to provide a detailed failure analysis on the root of the problem and contributing factors.Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Fitting Finishes

If you are looking for the perfect fitting finish, our Peentex surface texturing make surfaces easier to clean, disguise mild blemishes and can be used to create highly decorative finishes for fittings.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Flame Spray Coatings

Flame spraying is a thermal spraying coating process using the combustion of a fuel gas with oxygen in order to meal a spray coating material which can then be propelled to the substrate.

This process creates a high quality and cost effective surface coating for applying metallic and ceramic coatings.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Fluregiene 200™

Introducing Fluregiene 200™

Curtiss-Wright Surface Technologies, Everlube® Coating Products have partnered with BioCote® to expand their fluoropolymer coating product range to create Fluregiene 200™: an antimicrobial coating that is ideally suited for many surfaces and environments.

Based on existing Everlube® coating technology, the new Fluregiene 200™ is a unique fluoropolymer coating that offers low friction, easy-clean properties combined with superb chemical and abrasion resistance. With a view to improving hygiene standards, Everlube® Coatings have integrated BioCote® antimicrobial technology to protect the coating from microbes such as bacteria, mould and fungi. Benefits of applying antimicrobial technology into the Fluregiene 200™ include:

Anti-fouling

- Low COF Surface coating (0.08 – 0.2 static)

- Corrosion resistance and excellent chemical resistance

- Excellent chip and abrasion resistance

- Reduces and prevents build-up of contaminates

- Excellent flexibility

- Dirt and debris less likely to attach to the surface

Microbial & bacteria growth inhibitor

- Using patented BioCote® antimicrobial technology against microbial growth

- Inhibits and reduces microbial growth on protected coating

- Protects treated surfaces against bad odours, staining and material degradation

Easy clean and reduced cleaning intervals

- Provides continual microbial reduction on coating

- High PTFE content allows easy wipe down and cleaning

- Provides more hygienic and cleanable surface than brushed or finished steels

Applicable to a wide range of parts and components such as door handles, elevator buttons, airport seating and gym equipment, the Fluregiene 200™ will be highly beneficial for these surfaces. BioCote® also has real-life data to support the application of this antimicrobial technology in environments such as health care, transport, education, public areas and much more.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Fluregiene 200™

Fluregiene 200™ provides protection for hygiene conscious parts and surfaces

• Excellent corrosion resistance

• Low friction anti-fouling and anti-stick properties

• Durable and easy to clean/wipe down

• Permanently applied to metals, alloys and plastics

• Built-in antimicrobial technology actively reduces microbes on the surface of the coating.

• Reduces fungal growth and surfaces stay fresh longer

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

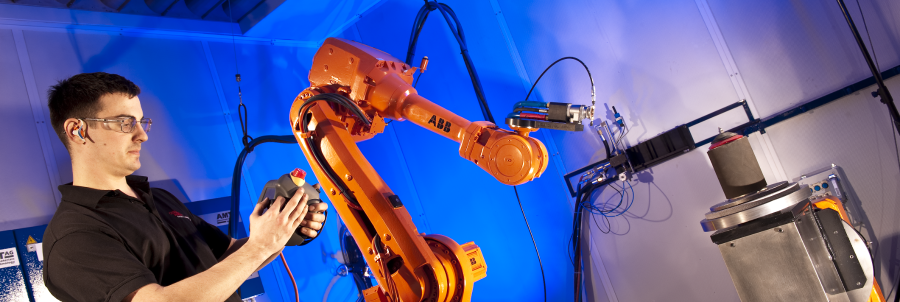

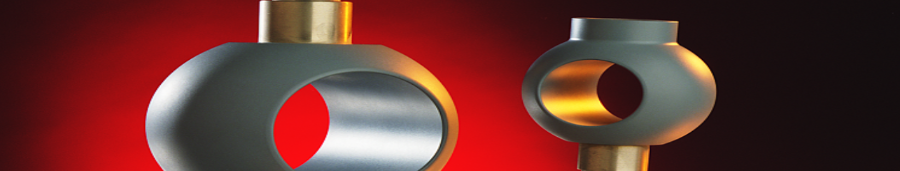

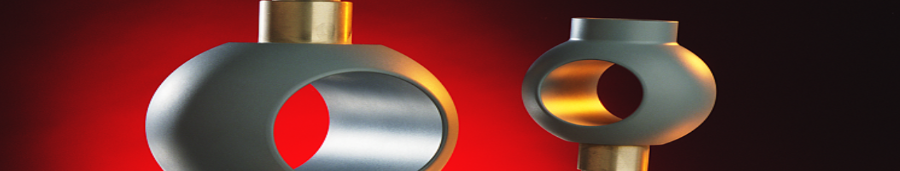

Gas Turbine Component Repair

At Curtiss Wright Surface Technologies we can repair gas turbines for many types of fatigue and corrosion as well as correcting shapes of distorted components.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Gas Turbine Engine Thermal Spray Coating

Our thermal spray coatings are ideal for use on gas turbine engines as they provide thermal management and protection from corrosion.

Request a Quote Supplied by Curtiss-Wright Surface Technologies