Curtiss-Wright Surface Technologies

Curtiss-Wright Surface Technologies (CWST) provides high quality surface treatments which will improve the life and performance of critical components through its global network of over 70 operating divisions and specialist onsite teams. Our surface treatments have been successfully used by OEM’s in major industries such as aerospace, automotive, oil & gas and power generation for many years.

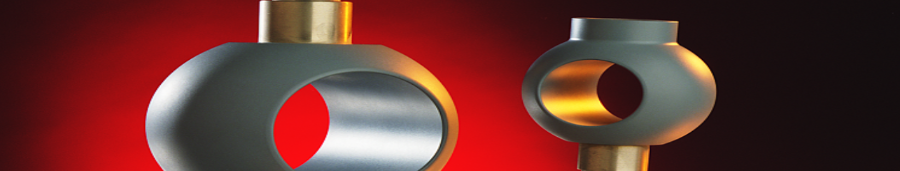

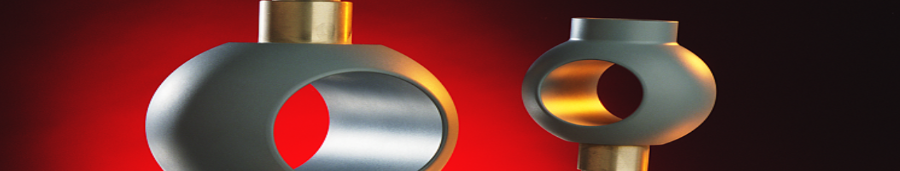

Metal Improvement Company (Newbury Division) offer quality metallurgical solutions to improve the performance of metal. With advanced technology, these improvements can be integrated into products when required and can dramatically enhance lifetimes improve fatigue strength, precision shaping, selective hardness and surface finish.

At Metal Improvement Company (Newbury Division), we deliver our innovative enhancements to our customers and help to create new state of the art products. We offer laser peening, peen forming, controlled shot peening, superfinishing and solid film lubricant coatings.

We are located in the UK with divisions in Evesham, Earby, Sunderland, Newbury, Derby, and Chester.

-

-

-

This detailed video from Curtiss-Wright Parylene showcases the parylene coating process; from beginning to the end; to help you to understand how you can add barrier protection to your medical and electronic parts. For more information on our parylene coatings, please visit our dedicated website - http://bit.ly/2bpftH8 To subscribe to the Curtiss-Wright channel, click here - http://bit.ly/2bp1HEx

-

Watch this video demonstration from Curtiss-Wright Parylene and find out more about how Parylene conformal coating protects electronic components. To discover more about electronic coatings, click here - http://bit.ly/2bY1RF9 Click here to subscribe to the Curtiss-Wright channel- http://bit.ly/2bp1HEx

-

Watch the Curtiss-Wright Parylene video demonstration which explains how highly conformal, reliable, bio compatible Parylene medical coatings help medical device manufacturing aids and delivery systems. For more info on coatings for medical devices, click here - http://bit.ly/2bphbIv To keep up-to-date with the latest Parylene videos, subscribe to the Curtiss-Wright channel - http://bit.ly/2bp1HEx

-

Watch Parylene's video which demonstrates how Parylene conformal coatings protect plastics and elastomers. At Curtiss-Wright Parylene, we offer quality and professional service to all our customers. To find out more about our services, click here - http://bit.ly/2bGaT5e To subscribe to the Curtiss-Wright channel - http://bit.ly/2bp1HEx

-

Curtiss-Wright overcome engineering challenges. Our highly engineered parylene surface treatments prevent premature failure, protect and improve the performance of critical components in harsh environments. This video from Curtiss-Wright will provide you with a comprehensive overview of Parylene's coating process. Parylene Coating is an ultra-thin film polymer coating, predominantly suitable for the automotive, aerospace, electronics and medical industries. Discover more about parylene coatings - http://bit.ly/2bpftH8 Subscribe to the Curtiss-Wright YouTube channel - http://bit.ly/2bp1HEx

-

Surface Technologies, a division of Curtiss Wright, delivers highly engineered processes worldwide and specialises in on-site work. This video demonstrates how Thermal Spray HVOF and Flame Spray coatings are applied. These engineered coating solutions protect components from high temperatures and environmental damage. To find out more about thermal coating, click here - http://bit.ly/2b992KB Subscribe to our channel - http://bit.ly/2bp1HEx

-

Curtiss-Wright supplies, designs and manufactures highly engineered coating solutions for a diverse range of markets. Controlled shot-peening is a cost effective metal treatment that can be performed on components of any shape and size to prevent corrosion, wear and fatigue in critical component. This video from EM Coating Services gives a comprehensive overview and demonstration of the controlled shot peening process. For more info on shot peening, click here – http://bit.ly/2bvI7Wx Click here to subscribe to the Curtiss-Wright channel - http://bit.ly/2bp1HEx

-

Watch Curtiss-Wright Surface Technologies’ video and discover how the HVOF coating process works to protect components from exposure to high temperatures, wear, corrosion and oxidation. Thermal spray coating can also be used for the restoration of worn components, such as gas turbine and compressor parts. To discover more about our thermal coatings, visit our website - http://bit.ly/2b992KB Want to see the latest videos as they are uploaded? Subscribe today – http://bit.ly/2bp1HEx

-

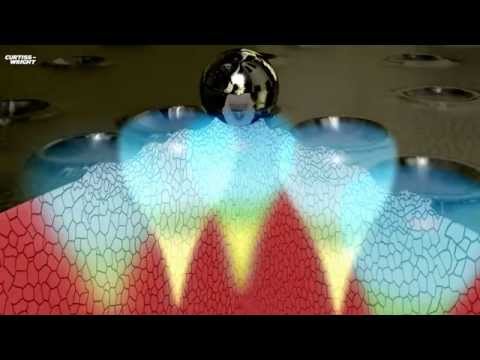

Curtiss-Wright supplies, designs and manufactures highly engineered coating solutions for a diverse range of markets. Controlled shot-peening is a cost effective metal treatment that can be performed on components of any shape and size to prevent corrosion, wear and fatigue in critical component. This video from EM Coating Services provides an overview of how controlled shot peening induces a beneficial residual compressive stress for the prevention of premature fatigue and component failure. For more info on shot peening, click here – http://bit.ly/2bvI7Wx To discover more about our component coating services, click here - http://bit.ly/2bb5vsm Click here to subscribe to the Curtiss-Wright channel - http://bit.ly/2bp1HEx

-

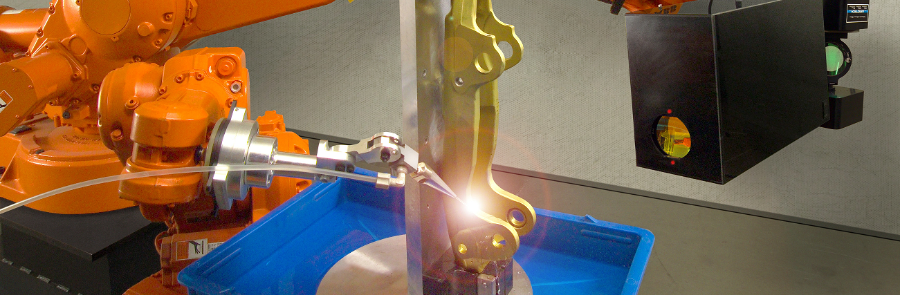

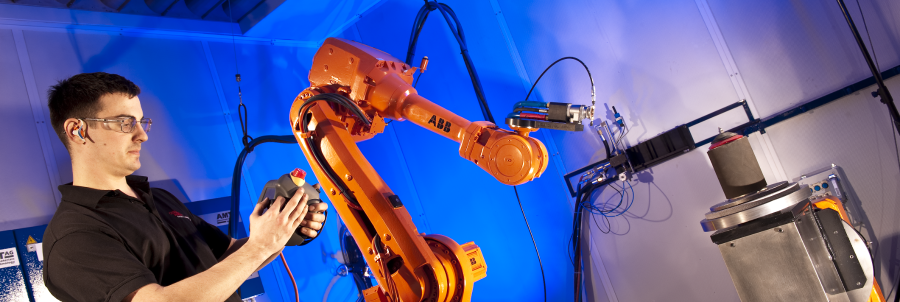

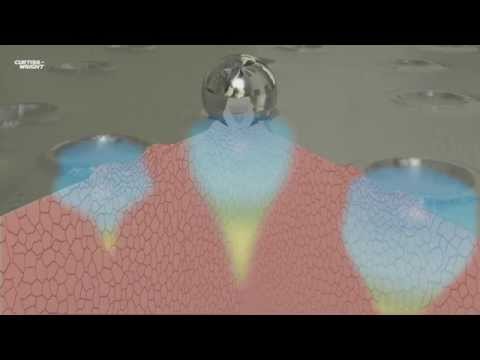

Curtiss-Wright Surface Technologies offer a range of component coating services including laser peening. Laser peening is making an important impact on industry, following the major transition from a laboratory research and development activity to reliable and production qualified technology. The technique induces exceptionally deep residual compresses stresses to enhance the fatigue strength and prevent crack irritation of critical metallic components. It also offers designers the ability to surgically place residual compressive stress into key areas of the components. For more information on laser peening, please click here –http://bit.ly/2bIMoWd To see the latest videos from Curtiss-Wright Surface Technologies, subscribe now - http://bit.ly/2bp1HEx

-

Curtiss-Wright Surface Technology (formerly known as the Metal Improvement Company) have created this innovative animation to showcase the benefits of shot peening and how the process induces residual compressive stresses on a surface. This process enhances the performance and extends the life of critical components and is used extensively in the aerospace, automotive, and oil and gas markets. To find out more about controlled shot peening, click here - http://bit.ly/2bvI7Wx Be the first to watch our latest videos. Click here to subscribe to our channel - http://bit.ly/2bp1HEx

-

Curtiss-Wright Surface Technologies (formerly known as Metal Improvement Company) has produced this video to demonstrate the benefits of the controlled shot peening process and how this technique can strengthen your critical components, leading to higher performance levels. Click here to learn more about shot peening - http://bit.ly/2bvI7Wx Want to keep up-to-date with our latest videos? Subscribe to our channel - http://bit.ly/2bp1HE