Curtiss-Wright Surface Technologies

Curtiss-Wright Surface Technologies (CWST) provides high quality surface treatments which will improve the life and performance of critical components through its global network of over 70 operating divisions and specialist onsite teams. Our surface treatments have been successfully used by OEM’s in major industries such as aerospace, automotive, oil & gas and power generation for many years.

Metal Improvement Company (Newbury Division) offer quality metallurgical solutions to improve the performance of metal. With advanced technology, these improvements can be integrated into products when required and can dramatically enhance lifetimes improve fatigue strength, precision shaping, selective hardness and surface finish.

At Metal Improvement Company (Newbury Division), we deliver our innovative enhancements to our customers and help to create new state of the art products. We offer laser peening, peen forming, controlled shot peening, superfinishing and solid film lubricant coatings.

We are located in the UK with divisions in Evesham, Earby, Sunderland, Newbury, Derby, and Chester.

Filter products and services

-

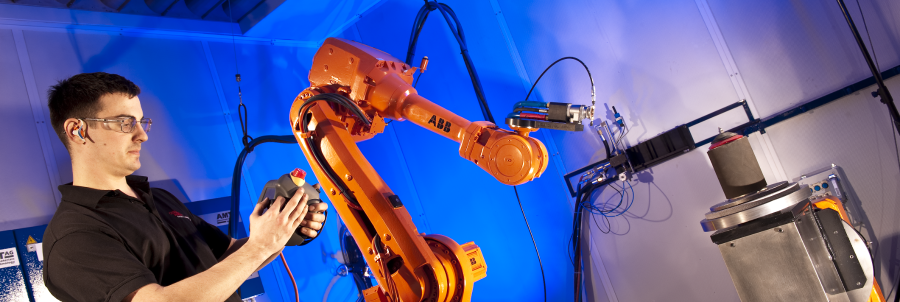

High Velocity Oxy-Fuel Coatings

Our HVOF spray coatings can be used over more traditional coating methods. We can accurately control the temperature of the bulk substrate avoiding and detrimental effects of heat on the material properties.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Intake Section Thermal Spray Coating

Our thermal spray coatings are used on many aerospace components such as the intake section because of the protection they give against corrosion and erosion

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

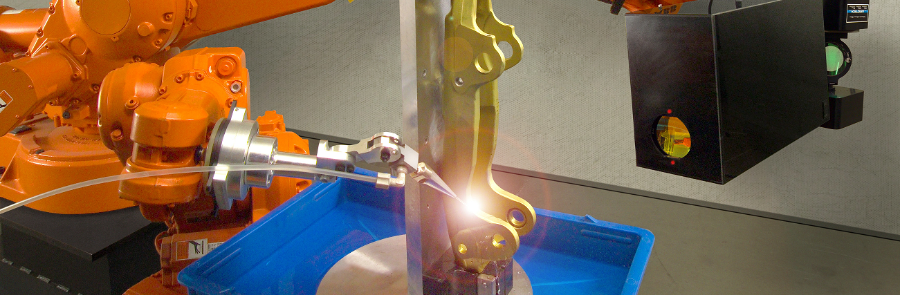

Laser Shock Peening

Laser peening induces compressive stress with precision accuracy into key areas of a component up to 5 to 10 times deeper than other conventional cold working techniques.Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Materials Analysis and Testing

IMR Test Labs offer mechanical and metallurgical testing including material testing, failure analysis, chemical analysis and weld testing to ensure design and manufacturing integrity.Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Mechanical Testing

IMR Test Labs offer the latest in mechanical testing services to meet the standards of a wide range of markets. We can provide fatigue testing, thermal spray coatings analysis, metallurgical and failure analysis. Our mechanical testing is commonly used by companies within in the oil and gas, aerospace, power generation and medical industries.

For more information, please contact us!

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Metallurgical Analysis

Metallurgical analysis can be used to test materials to see if they meet the required specifications to ensure durability for the intended use.

The metallurgical analysis reveal the makeup of your materials with macro, micro and SEM examinations.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

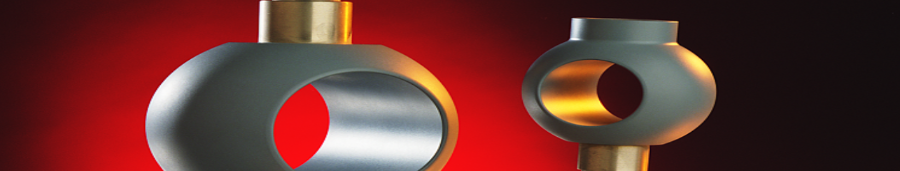

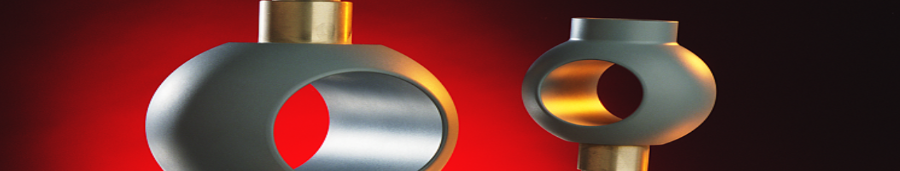

MoS2 Coatings

MoS2 coatings also known as Moly Coatings are often used on products where operating temperatures, load carrying capacity and coefficient of friction are primary concerns.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Non-abrasive Finishing

Using non-abrasive finishing Curtiss Wright Surface Technology can provide mirror like finishes.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Nonstick Coatings

Nonstick coatings fall under the PTFE coatings category. Most commonly used to coat cookware they can also be used on engineering equipment as a protective layer to prevent wear.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Onsite Services

Specialist teams can be mobilised worldwide to repair large or fixed equipment, reducing shipping costs and downtime to the same specification as in-house processing.Request a Quote Supplied by Curtiss-Wright Surface Technologies