Curtiss-Wright Surface Technologies

Curtiss-Wright Surface Technologies (CWST) provides high quality surface treatments which will improve the life and performance of critical components through its global network of over 70 operating divisions and specialist onsite teams. Our surface treatments have been successfully used by OEM’s in major industries such as aerospace, automotive, oil & gas and power generation for many years.

Metal Improvement Company (Newbury Division) offer quality metallurgical solutions to improve the performance of metal. With advanced technology, these improvements can be integrated into products when required and can dramatically enhance lifetimes improve fatigue strength, precision shaping, selective hardness and surface finish.

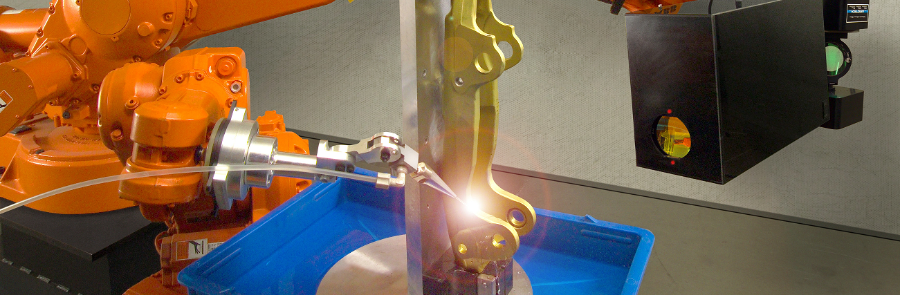

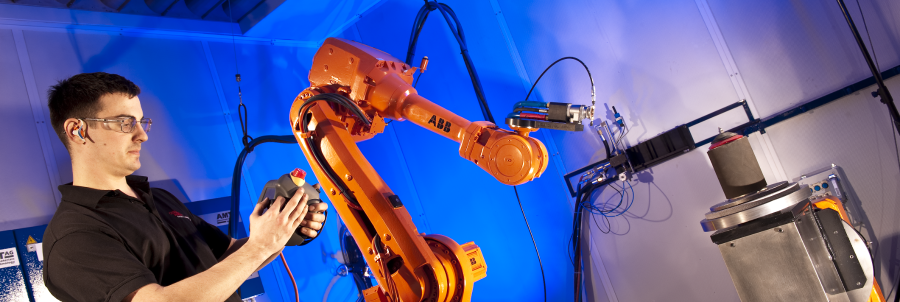

At Metal Improvement Company (Newbury Division), we deliver our innovative enhancements to our customers and help to create new state of the art products. We offer laser peening, peen forming, controlled shot peening, superfinishing and solid film lubricant coatings.

We are located in the UK with divisions in Evesham, Earby, Sunderland, Newbury, Derby, and Chester.

Filter products and services

-

Parylene Coatings

CURTISS-WRIGHT PARYLENE COATINGS

True to the Curtiss-Wright tradition of excellence and providing highly engineered solutions, our Parylene Coatings bring high reliability to critical components operating in the harshest of environments. Parylene coatings are highly lubricious, dry film and environmentally protective conformal coatings applied to metals, elastomers, electronics, glass, ceramics and plastics. Our coating services provide the very best thin film conformal coating protection for critical components in many industries including Medical Device, Aerospace, Defence, Automotive and Electronics.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Parylene Conformal Coatings

Parylene Conformal Coatings commonly used in the medical and electronic industry due to its ultra thin coating it reduces friction and protects components from the environment.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Parylene Conformal Coatings

Parylene is a highly lubricious and ultra thin conformal coating with outstanding chemical, moisture and electrical barrier protection for metals, elastomers, electronics and plastic.Request a Quote Supplied by Curtiss-Wright Surface Technologies -

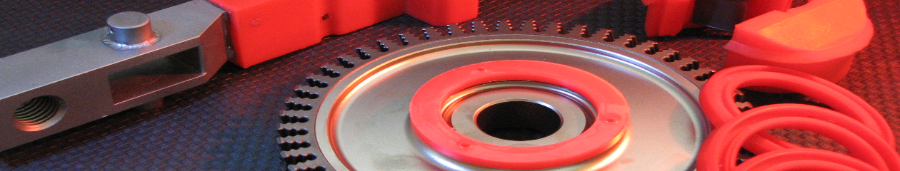

Peenflex Protective Mouldings

PEENFLEX damage and abrasion resistant mouldings protect parts through the various stages of processing, lifting, moving, storage and despatch. Uniquely made for each application.Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Peentex Architectural Finishes

PEENTEX protects internal and external cladding, street furniture and signage. Creates a decorative finish for architectural purposes on metal, glass, wood and acrylic. Non-slip textured finish for tooling and equipment.Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Plasma Electrolytic Oxidation

Plasma Electrolytic Oxidation (PEO) is a method of producing surface coatings which applies a ceramic layer onto the surface of a light alloy. It holds several key advantages over more traditional surface coatings, making it popular in automotive, aerospace and manufacturing.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

PTFE Coatings

PTFE Coatings is a fluoropolymer with excellent low friction and non-stick properties.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Shot Peen Forming

Creates curvature in aircraft wing skins to enhance lift and efficiency and to protect against fatigue. Also used to correct the distortion of components following manufacturing.Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Shot Peen Forming Airframe Components

We also provide shot peen forming for aircraft components. Aircraft components that have been shot peened show increased resistance to flexural bending fatigue and stress corrosion cracking.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

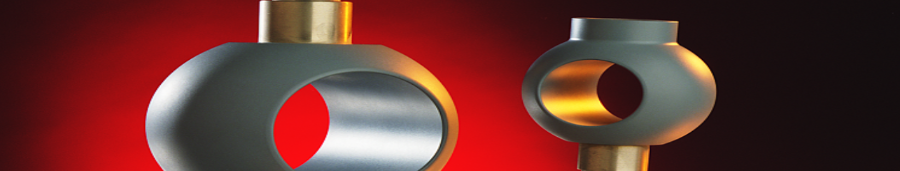

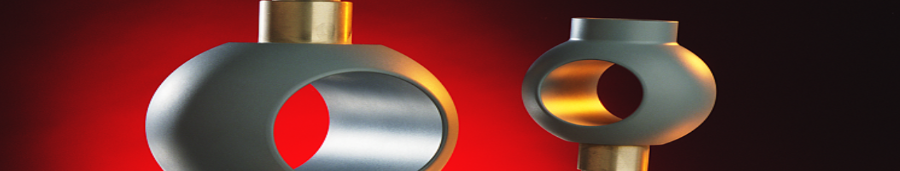

Shot Peen Forming Crankshafts

Shot peening forming is ideal for creating the complex curvatures in crankshafts. The use of shot peening to form crankshafts can increase resistance to flexural bending fatigue and stress corrosion cracking.

Request a Quote Supplied by Curtiss-Wright Surface Technologies