Curtiss-Wright Surface Technologies

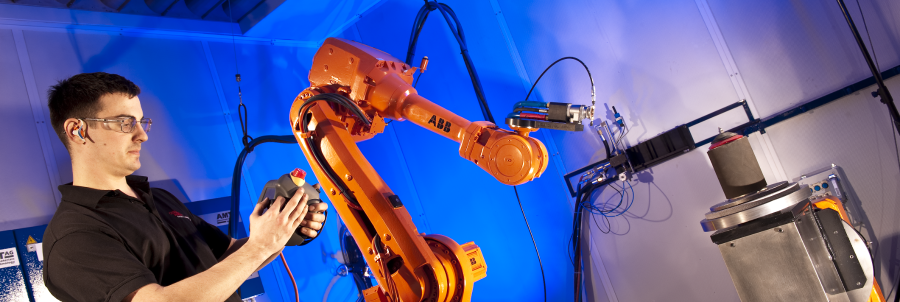

Curtiss-Wright Surface Technologies (CWST) provides high quality surface treatments which will improve the life and performance of critical components through its global network of over 70 operating divisions and specialist onsite teams. Our surface treatments have been successfully used by OEM’s in major industries such as aerospace, automotive, oil & gas and power generation for many years.

Metal Improvement Company (Newbury Division) offer quality metallurgical solutions to improve the performance of metal. With advanced technology, these improvements can be integrated into products when required and can dramatically enhance lifetimes improve fatigue strength, precision shaping, selective hardness and surface finish.

At Metal Improvement Company (Newbury Division), we deliver our innovative enhancements to our customers and help to create new state of the art products. We offer laser peening, peen forming, controlled shot peening, superfinishing and solid film lubricant coatings.

We are located in the UK with divisions in Evesham, Earby, Sunderland, Newbury, Derby, and Chester.

Filter products and services

-

Shot Peen Forming Rocket Structure

Thanks to the controlled process of shot peen forming surfaces can be manipulated into complex contours for example those found on a rocket structure.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Shot Peen Forming Wing Skins

Curtiss Wright Surface Technologies specialises in shot peen forming wing skins. By carrying out the shot peen forming process is the preferred method of forming aerodynamic contours of aircraft wing skins.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

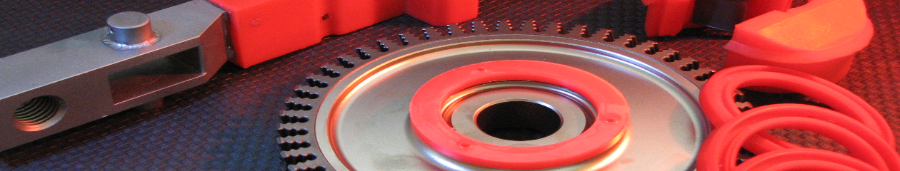

Shot Peening

Controlled shot peening is a cold working process applied using spherical media known as shot. As each piece of shot hits the surface it creates an indentation where the surface will attempt to yield but is restrained by the substrate material. This conflict causes the substrate material to compress creating a beneficial compressive residual stress which makes the surface resistant to crack initiation and propagation and in the process removes any prior manufacturing tensile stresses.

For more information contact 01635 279621 or email eurosales@cwst.com. Also our website address is www.cwst.co.uk

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Signage Finishes

Our Peentex surface texturing improves surfaces resistance to wear and tear making the finish ideal for signage in high traffic areas.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Steam Turbine Component Repair

Our team can be mobilized worldwide to repair steam turbine components for corrosion and fatigue.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Street Furniture Finishes

Our architectural finishes give street furniture improved damage tolerance and resistance to graffiti.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

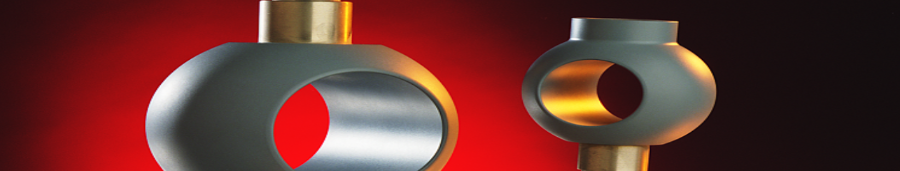

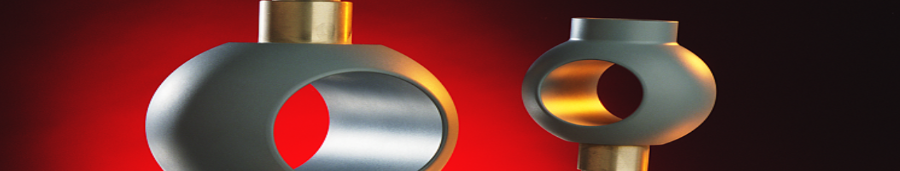

Superfinishing Bearings

Our super finishing process ensures your bearings are given mirror like finishes for reduced friction.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Superfinishing Gears

By superfinishing gears, they are more likely to have reduced contact fatigue giving you longer lasting parts.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Teflon Coatings

Tefelon coatings are the original fluoropolymer coatings. Teflon coatings are renowned for their versatility which means they can be applied to a variety of substrates, parts and configurations.

Teflon coatings are applied like any other paint and baked to a tough finish and offer a balance of properties to create a low coefficient of friction.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

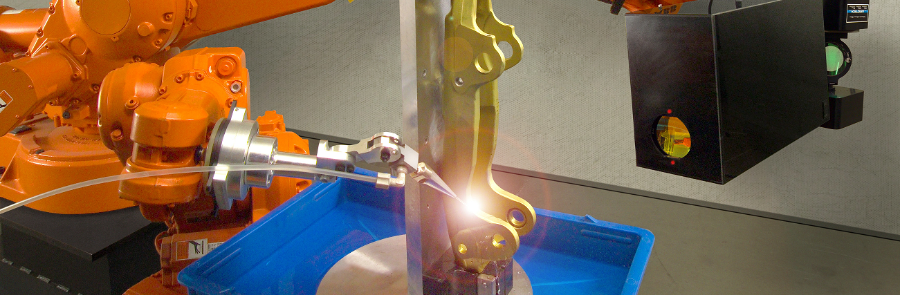

Thermal Plasma and HVOF Spray Coatings

Wear resistant and barrier coatings such as HVOF, arc and flame spray, protecting against high temperatures, wear, corrosion and oxidation, as well as restoring parts to their original condition.Request a Quote Supplied by Curtiss-Wright Surface Technologies