Curtiss-Wright Surface Technologies

Curtiss-Wright Surface Technologies (CWST) provides high quality surface treatments which will improve the life and performance of critical components through its global network of over 70 operating divisions and specialist onsite teams. Our surface treatments have been successfully used by OEM’s in major industries such as aerospace, automotive, oil & gas and power generation for many years.

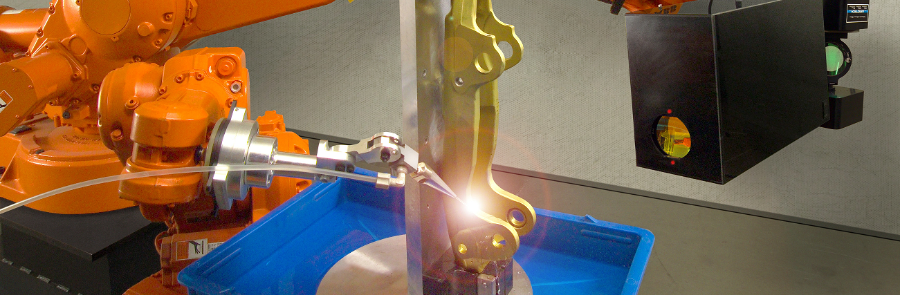

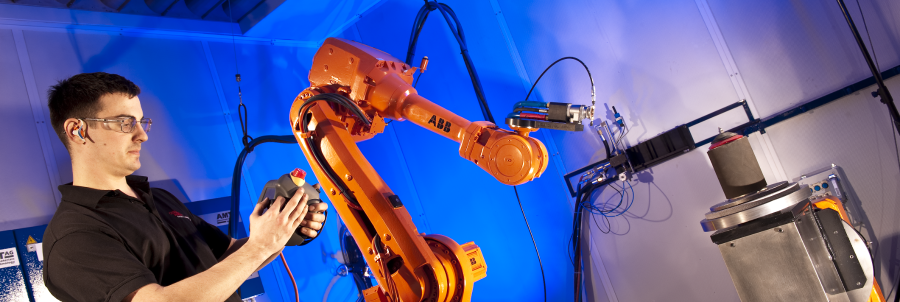

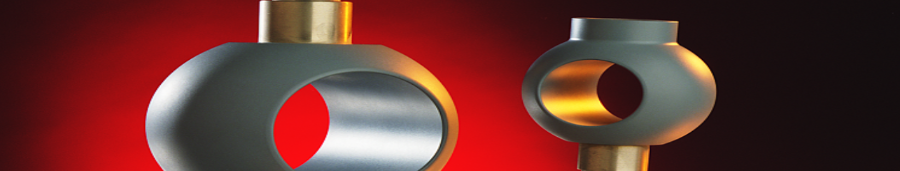

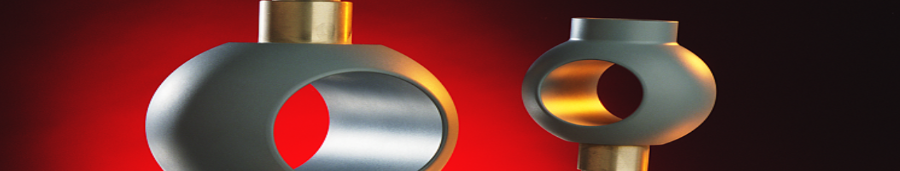

Metal Improvement Company (Newbury Division) offer quality metallurgical solutions to improve the performance of metal. With advanced technology, these improvements can be integrated into products when required and can dramatically enhance lifetimes improve fatigue strength, precision shaping, selective hardness and surface finish.

At Metal Improvement Company (Newbury Division), we deliver our innovative enhancements to our customers and help to create new state of the art products. We offer laser peening, peen forming, controlled shot peening, superfinishing and solid film lubricant coatings.

We are located in the UK with divisions in Evesham, Earby, Sunderland, Newbury, Derby, and Chester.

Filter products and services

-

Thermal Spray Coatings

Our thermal coating sprays are used throughout the aerospace, automotive, power generation, oil and gas industries. Thermal spray coatings are great for protecting components from wear, corrosion, fatigue, oxidation and high temperatures.

Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Wet Treatments (Anodising)

Wet processing techniques improve atmospheric and chemical corrosive resistance and also enhance the application of paint primer and adhesives.Request a Quote Supplied by Curtiss-Wright Surface Technologies -

Zinc Rich Coatings

Zinc coatings are a well-suited for coating iron and steel products that may need a corrosion protection coating.

Curtiss-wright Surface Technologies can offer a range of zinc coatings, coating thickness and coating weight dependant on your product needs.

Request a Quote Supplied by Curtiss-Wright Surface Technologies