J.R. GILBERT ENGINEERING LIMITED

Founded in 1983, JR Gilbert Engineering offers precision and general engineering to a variety of industries throughout the UK and Ireland. We have an extensive range of engineering services including : 3 Axis CNC Machining, 5 Axis CNC Machining, Gear Cutting, Surface Grinding, Boring, Slotting, Fabrication & Welding, CAD/CAM Services, Conventional Machining and Waterjet Cutting. We are proud to be one of the largest CNC manufacturing companies in South Wales.

At the start of 2023, we took possession of another 10,000 Sq Ft building attached to our existing 10,000 Sq Ft on our Oakdale Site. In the last 6 months we have added a Large Dugard 2200x1000x1000 CNC milling machine to our capacity list and have just taken delivery of a Mazak 35Y CNC Lathe (Capable of turning 550 Ø x 1500mm). All of this, coupled with having bought another Bridgeport CNC machine and an OMAX Precision Waterjet Cutter within the last 18 months, demonstrates our vision in investing into the business to help us grow forward along with the manufacturing industry.

Having all these services in-house and under one roof, Gilbert Engineering is well placed to meet the high demands of the manufacturing sector. With a commitment to high-quality manufacturing, we adhere to ISO9001:2015 standards, ensuring all components are meticulously manufactured and inspected. From bespoke machines, one off components, repairs to existing equipment, custom gears and batch runs, we can do it all.

Filter products and services

-

CNC Milling Companies

We have a comprehensive range of CNC Turning Machines that can handle 3000mm between centres 350 Ø over saddle. All our products are in accordance with the ISO 9001:2015 standard ensuring they are inspected at every stage of the manufacturing process and are delivered at the highest quality.

Our capabilities include :

- Mazak Integrex 35Y 1500mm x 550 Ø Mill Turn

- Doosan 300M with Live Tooling

- DSG 2200 x 600 Ø

- Small Haas CNC Lathe

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

CNC Milling Companies

Thanks to a comprehensive range of modern CNC machinery and years of experience acquired working with conventional machines; we offer high-quality precision-machined components. We have 3 and 5 axis machining capabilities in our factory. All our products are in accordance with the ISO 9001:2015 standard ensuring they are inspected at every stage of the manufacturing process and are delivered at the highest quality.

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

CNC Turning

We have a comprehensive range of CNC Turning Machines that can handle 3000mm between centres 350 Ø over saddle. All our products are in accordance with the ISO 9001:2015 standard ensuring they are inspected at every stage of the manufacturing process and are delivered at the highest quality.

Our capabilities include :

- Mazak Integrex 35Y 1500mm x 550 Ø Mill Turn

- Doosan 300M with Live Tooling

- DSG 2200 x 600 Ø

- Small Haas CNC Lathe

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

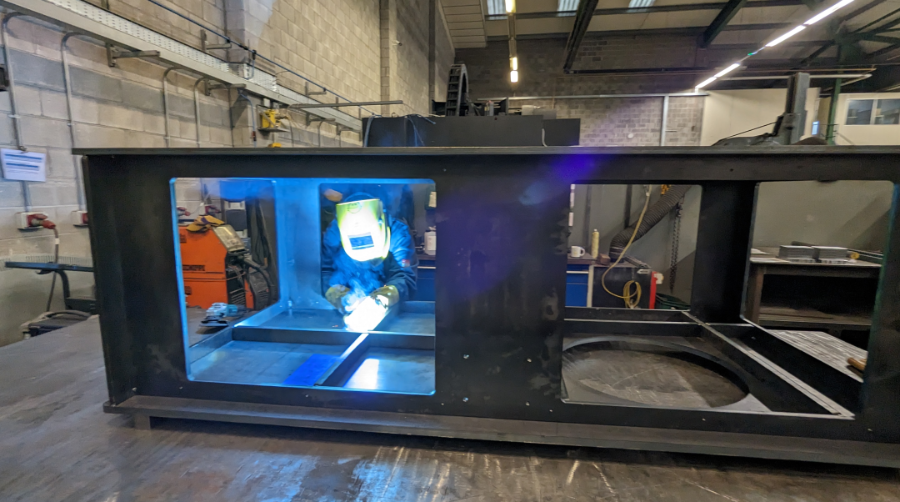

Coded Welding

We provide extensive coded welding and fabrication services at JR Gilbert Engineering. Our services include :

- MIG Welding

- TIG Welding

- Stick Welding

- Arc Welding

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

Fabrications

We provide extensive coded welding and fabrication services at JR Gilbert Engineering. Our services include :

- MIG Welding

- TIG Welding

- Stick Welding

- Arc Welding

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

Gearbox Refurbishment

Our Engineers disassemble the gearbox for cleaning and inspection. Our budget quotation can also include our finding if it’s required – please let us know. Detailed quotations are sent via email however when a job is really urgent making a phone call to discuss and speed up the service is also an option. Shafts / gears can be made from scratch and bearings seals changed as required. If the casing has been damaged, we can weld / sleeve and re bore back to size. We will re assemble and normally ship with no oil, this will be clearly stated. We also have the capability to completely reverse engineer and manufacture gearboxes if an item has become obsolete. The casing will be fabricated, stress relieved then machined. Gears and shafts will be manufactured and bearings seals fitted.

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

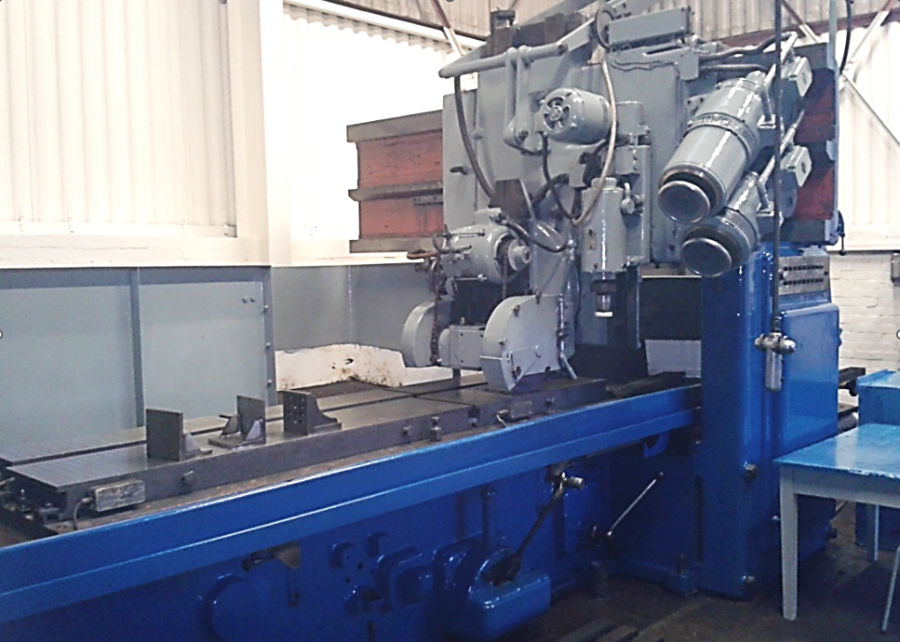

Gear Cutting

JR Gilbert Engineering have an extensive range of gear cutters for the manufacture of precision gears, worms and wheels, racks and pinions, spur and helical gears, straight and bevel gears, internal and external splines and keyways. Utilising our gear cutters along with the CNC lathes and Milling machines we can manufacture a gear you require from raw billet.

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

Gear Racks

JR Gilbert Engineering has an extensive range of gear cutters for the manufacture of precision gears, worms and wheels, racks and pinions, spur and helical gears, straight and bevel gears, internal and external splines and keyways. From the manufacture of large gears for cranes and heavy machinery to much smaller gears for gear boxes and machine repair. All our products are in accordance with the ISO 9001:2015 standard ensuring they are inspected at every stage of the manufacturing process and are delivered at the highest quality.

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

Guillotine Blade Refurbishment

JR Gilbert Engineering can provide customers with high quality Guillotine Blade Refurbishment services. All our products are in accordance with the ISO 9001:2015 standard ensuring they are inspected at every stage of the manufacturing process and are delivered at the highest quality.

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

Guillotine Knife Refurbishment

JR Gilbert Engineering can provide customers with high quality Guillotine Knife Refurbishment Services. All our products are in accordance with the ISO 9001:2015 standard ensuring they are inspected at every stage of the manufacturing process and are delivered at the highest quality

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED