J.R. GILBERT ENGINEERING LIMITED

Founded in 1983, JR Gilbert Engineering offers precision and general engineering to a variety of industries throughout the UK and Ireland. We have an extensive range of engineering services including : 3 Axis CNC Machining, 5 Axis CNC Machining, Gear Cutting, Surface Grinding, Boring, Slotting, Fabrication & Welding, CAD/CAM Services, Conventional Machining and Waterjet Cutting. We are proud to be one of the largest CNC manufacturing companies in South Wales.

At the start of 2023, we took possession of another 10,000 Sq Ft building attached to our existing 10,000 Sq Ft on our Oakdale Site. In the last 6 months we have added a Large Dugard 2200x1000x1000 CNC milling machine to our capacity list and have just taken delivery of a Mazak 35Y CNC Lathe (Capable of turning 550 Ø x 1500mm). All of this, coupled with having bought another Bridgeport CNC machine and an OMAX Precision Waterjet Cutter within the last 18 months, demonstrates our vision in investing into the business to help us grow forward along with the manufacturing industry.

Having all these services in-house and under one roof, Gilbert Engineering is well placed to meet the high demands of the manufacturing sector. With a commitment to high-quality manufacturing, we adhere to ISO9001:2015 standards, ensuring all components are meticulously manufactured and inspected. From bespoke machines, one off components, repairs to existing equipment, custom gears and batch runs, we can do it all.

Filter products and services

-

Helical Gear

JR Gilbert Engineering has an extensive range of gear cutters for the manufacture of precision gears, worms and wheels, racks and pinions, spur and helical gears, straight and bevel gears, internal and external splines and keyways. From the manufacture of large gears for cranes and heavy machinery to much smaller gears for gear boxes and machine repair. All our products are in accordance with the ISO 9001:2015 standard ensuring they are inspected at every stage of the manufacturing process and are delivered at the highest quality.

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

Internal and External Splines

JR Gilbert Engineering has an extensive range of gear cutters for the manufacture of precision gears, worms and wheels, racks and pinions, spur and helical gears, straight and bevel gears, internal and external splines and keyways. From the manufacture of large gears for cranes and heavy machinery to much smaller gears for gear boxes and machine repair. All our products are in accordance with the ISO 9001:2015 standard ensuring they are inspected at every stage of the manufacturing process and are delivered at the highest quality.

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

Internal Spur Gears

JR Gilbert Engineering has an extensive range of gear cutters for the manufacture of precision gears, worms and wheels, racks and pinions, spur and helical gears, straight and bevel gears, internal and external splines and keyways. From the manufacture of large gears for cranes and heavy machinery to much smaller gears for gear boxes and machine repair. All our products are in accordance with the ISO 9001:2015 standard ensuring they are inspected at every stage of the manufacturing process and are delivered at the highest quality.

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

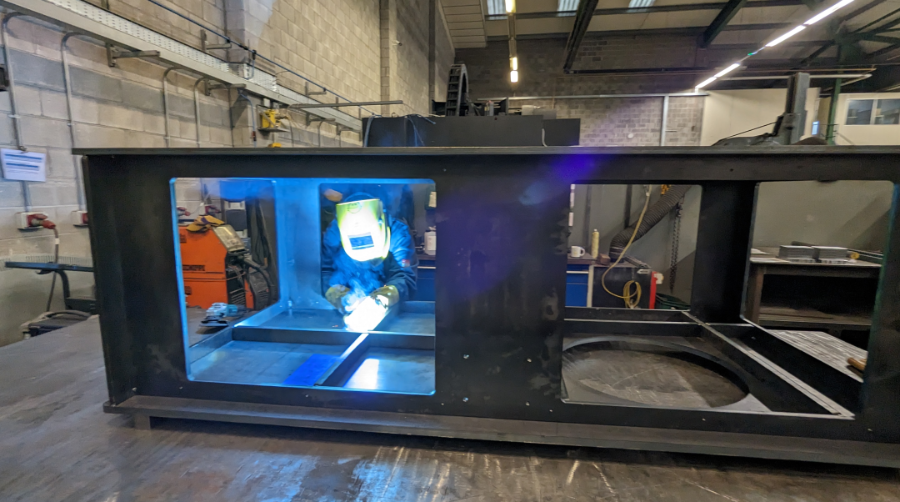

MIG Welding

We provide extensive coded welding and fabrication services at JR Gilbert Engineering. Our services include :

- MIG Welding

- TIG Welding

- Stick Welding

- Arc Welding

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

Punch Tooling Refurbisment

JR Gilbert Engineering can provide customers with high quality Punch Tooling Refurbishment Services. All our products are in accordance with the ISO 9001:2015 standard ensuring they are inspected at every stage of the manufacturing process and are delivered at the highest quality.

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

Rack and Pinion Gear Manufacture

JR Gilbert Engineering has an extensive range of gear cutters for the manufacture of precision gears, worms and wheels, racks and pinions, spur and helical gears, straight and bevel gears, internal and external splines and keyways. From the manufacture of large gears for cranes and heavy machinery to much smaller gears for gear boxes and machine repair. All our products are in accordance with the ISO 9001:2015 standard ensuring they are inspected at every stage of the manufacturing process and are delivered at the highest quality.

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

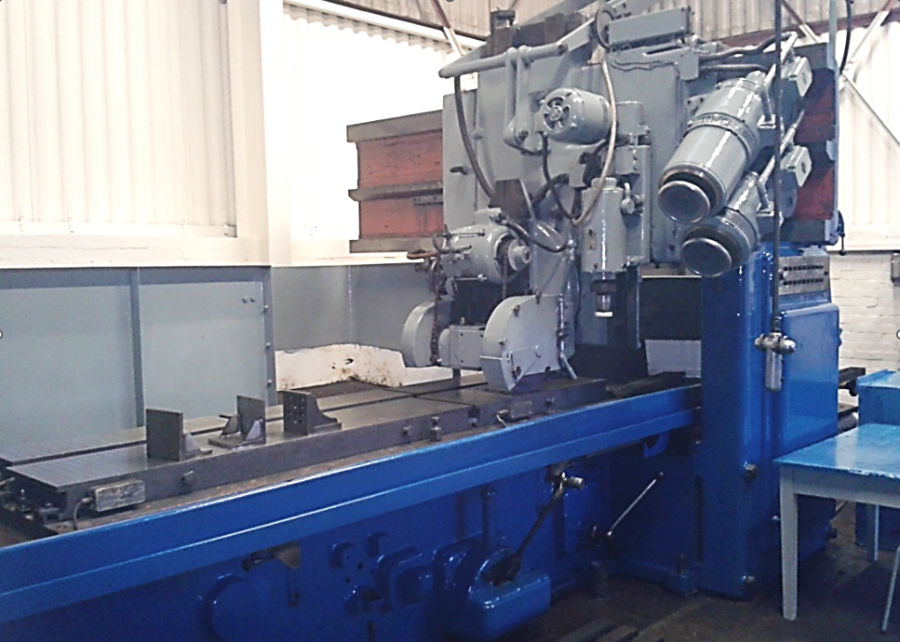

Slotting

Slotting forms an essential part of gear cutting, with a capacity of 1000mm diameter and a 12″ stroke we can slot most internal keyways as well as other shapes which can’t be produced using a rotary tool e.g. square corners.

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

Spur and Helical Gear Manufacture

JR Gilbert Engineering has an extensive range of gear cutters for the manufacture of precision gears, worms and wheels, racks and pinions, spur and helical gears, straight and bevel gears, internal and external splines and keyways. From the manufacture of large gears for cranes and heavy machinery to much smaller gears for gear boxes and machine repair. All our products are in accordance with the ISO 9001:2015 standard ensuring they are inspected at every stage of the manufacturing process and are delivered at the highest quality.

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

Spur Gears

R Gilbert Engineering has an extensive range of gear cutters for the manufacture of precision gears, worms and wheels, racks and pinions, spur and helical gears, straight and bevel gears, internal and external splines and keyways. From the manufacture of large gears for cranes and heavy machinery to much smaller gears for gear boxes and machine repair. All our products are in accordance with the ISO 9001:2015 standard ensuring they are inspected at every stage of the manufacturing process and are delivered at the highest quality.

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED -

Stick Welding

We provide extensive coded welding and fabrication services at JR Gilbert Engineering. Our services include :

- MIG Welding

- TIG Welding

- Stick Welding

- Arc Welding

Request a Quote Supplied by J.R. GILBERT ENGINEERING LIMITED