Kohesi Bond

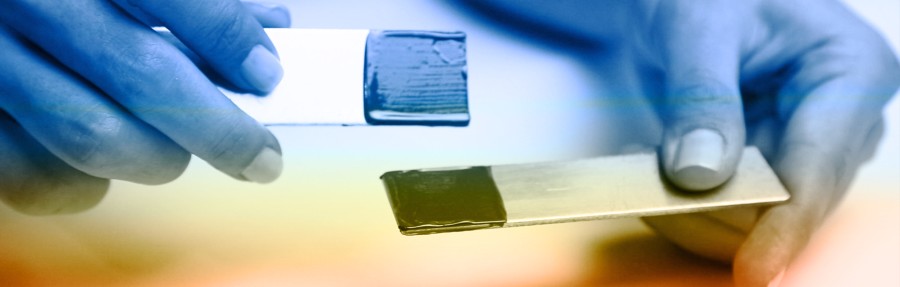

Kohesi Bond is a pioneer in manufacturing custom engineered adhesives, sealants, coatings, potting and encapsulation compounds. In November 2014, we started prototyping as a part of an interdisciplinary effort with the Institute of Chemical Technology, bringing together a team of technical experts to formulate specialty adhesive systems. Through persistent research, technical know-how and groundbreaking innovation we were able to create new compounds that had truly distinguished properties. In September 2015, we founded Kohesi Bond to further our research and manufacture first-rate, industry-ready products in our state of the art facility.

To deliver reliable solutions, we realised that one size does not fit all. Hence, our focus has been on offering tailor-made products, consistent quality and unparalleled expertise to our customers. We want to keep innovating new products with diverse chemistries that add more value to every application. By researching, formulating and testing each product all under the same roof, we are able to take a holistic approach to manufacturing exclusive adhesives and provide customers with an end-to-end solution.

Filter products and services

-

Chemically Resistant Epoxies

Kohesi Bond’s exclusive products offer resistance to a sweeping range of chemicals. Our specialty systems are designed specifically to withstand prolonged exposure to vigorous chemicals. Our chemically resistant systems are widely used in chemical tanks, piping, medical devices, processing plants, off-shore oil and gas industries and numerous other applications. We test our products for long-term immersions in a variety of acids, bases, alcohols, solvents, water, oils, fuels and sterilants among many others. Our reliable, expansive data is used to custom formulate products that meet specific end-user requirements.

POPULAR PRODUCTS

Request a Quote Supplied by Kohesi Bond -

Cryogenic Adhesives

Cryogenic Adhesives

Kohesi Bond custom formulates specialty epoxy systems that are capable of withstanding cryogenic temperatures and shocks. Cryogenic temperatures are typically referred to temperatures below -180°C (93.15K). Our cryogenic adhesives, sealants and coatings are capable of withstanding temperatures down to 4K. These unique products are commonly used in sensors, cryosurgery or cryotherapy, satellites, energy storage, high energy physics, nuclear magnetic resonance spectroscopy (NMR), magnetic resonance imaging (MRI), cryogenic transfer pumps and valves, blood banking and superconductivity applications. Distinct grades are available that offer electrical conductivity, thermal conductivity, optical clarity, electrical insulation and are capable of meeting stringent industrial certifications.

POPULAR PRODUCTS

Request a Quote Supplied by Kohesi Bond -

Electrically Conductive Adhesives

-

ELECTRICALLY CONDUCTIVE ADHESIVES

Kohesi Bond offers a comprehensive range of custom-made electrically conductive systems that suit your specific requirements. Electrical conductivity refers to a material’s ability to easily allow flow of electrical current. Various fillers are employed to make our epoxy systems excellent conductors of electricity. These include:

Silver Filled Adhesives: Silver filled systems offer the highest electrical conductivity and the lowest volume resistivity of <10-3 ohm-cm. They are commonly used to replace solder.

Silver-coated Nickel Adhesives: Silver-coated nickel filled products offer a more cost effective alternative to silver filled systems, while maintaining very low volume resistivity of < 0.005 ohm-cm.

Nickel Filled Adhesives: Nickel filled systems offer a cost effective solution where high electrical conductivity is required. Typically, they offer a low volume resistivity of 5 – 10 ohm-cm.

Graphite Filled Adhesives: Graphite filled products offer an economical solution while maintaining good electrical conductivity. They provide a non-magnetic bond, high lubricity and a volume resistivity of 50 – 100 ohm-cm.

Kohesi Bond’s superior electrically conductive adhesives, sealants and coatings are extensively used for wire-bonding, die attach, EMI/RFI shielding, electrostatic discharge, grounding and antistatic applications.POPULAR PRODUCTS

Request a Quote Supplied by Kohesi Bond -

-

FLAME RETARDANT EPOXIES

FLAME RETARDANT EPOXIES:

UL 94V-0: Underwriters Laboratories (UL) rates epoxies for their self extinguishing and flame retardant properties by performing extensive testing. These epoxies are useful in special potting and encapsulation applications and are rated up to 90°C. Kohesi Bond formulates customized epoxies that are capable of passing the most stringent UL flame retardant rating i.e. UL 94V-0.

FAR 25.853 (a) is a standard for flame retardancy as defined by the Federal Aviation Regulation to test a material’s compliance for use in airline cabin, cargo and interiors. This test involves burning a cured sample at a specific angle for a defined amount of time. The material’s flame retardancy is then measured in terms of the burn time, length and rate. The test is performed in both horizontal and vertical positions. The vertical test specification is more challenging as compared to the horizontal test specifications. However, depending on your application either one of the test specifications might be sufficient. Kohesi Bond offers innovative products that are capable of meeting these requirements.

POPULAR PRODUCTS

Request a Quote Supplied by Kohesi Bond -

HIGH STRENGTH ADHESIVES

HIGH STRENGTH ADHESIVES:

Kohesi Bond manufactures first-rate adhesives, sealants, coatings, potting and encapsulation compounds that offer sensational mechanical strength properties. Our highly dedicated team of engineers research and develop custom-made products that meet your specific end-requirements. Kohesi Bond's one and two component epoxy systems offer first-rate tensile, shear, compressive, peel, flexural and cleavage strength. These products are frequently used in the electronics, semiconductor, optical, medical, aerospace, automotive, oil and gas and specialty OEM applications. Our products are capable of meeting various industrial certifications, like NASA low outgassing (ASTM E-595), USP Class VI, ISO 10993-5, halogen free and UL 94 V-0 flame retardance. In addition, they maintain high bond strength at extreme temperatures (including cryogenic) as well as withstand harsh chemicals.

POPULAR PRODUCTS

Request a Quote Supplied by Kohesi Bond -

HIGH TEMPERATURE RESISTANT ADHESIVES

HIGH TEMPERATURE RESISTANT ADHESIVES:

Kohesi Bond offers a broad range of out of the ordinary epoxies and sodium silicate based products that can withstand extremely high temperatures. These high temperature adhesives, sealants, coatings, potting and encapsulation compounds are capable of holding up to temperatures more than 315°C (600°F). Our products are commonly employed in various oil and gas, electronics, medical, aerospace, automotive and optical applications, where good adhesion even at extreme temperatures is absolutely crucial. Depending on your application requirements, our adhesives can be customized to precisely suit them.

POPULAR PRODUCTS

Request a Quote Supplied by Kohesi Bond -

LOW COEFFICIENT OF THERMAL EXPANSION (CTE) EPOXIES

LOW COEFFICIENT OF THERMAL EXPANSION (CTE) EPOXIES:

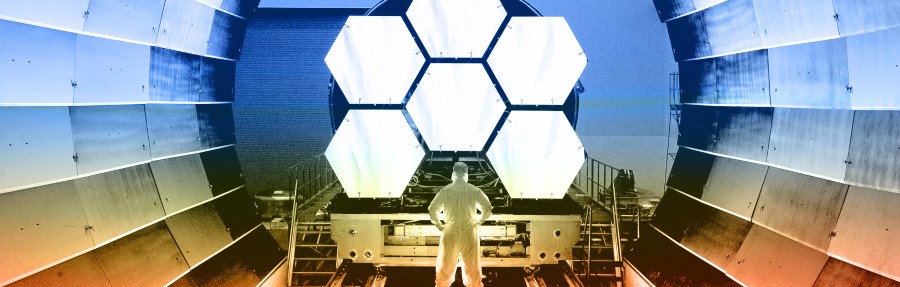

Coefficient of thermal expansion (CTE) characterizes the fractional change in a material’s size with change in temperature. Highly sensitive optical, aerospace, electronics, semiconductor and specialty OEM applications desire this change in size to be minimal. With the help of special fillers, Kohesi Bond has formulated first-rate epoxy adhesives, sealants and coatings with extremely low coefficients of thermal expansion. Our Low CTE epoxies are capable of passing stringent industrial certifications such as NASA standards for low outgassing (ASTM E-595). These dimensionally stable products offer low shrinkage, outstanding electrical insulation, superior thermal conductivity and phenomenal low and high temperature resistance. Our adhesives can be tailor-fitted to your specific application requirements.

POPULAR PRODUCTS

Request a Quote Supplied by Kohesi Bond -

Low Out Gassing Adhesives

LOW OUTGASSING ADHESIVES

ASTM E-595 test standard was developed by NASA for evaluating the low outgassing properties of adhesives, sealants, coatings, potting and encapsulation compounds. This special test was designed in order to determine the usefulness of a product for space and high vacuum applications. In addition, Kohesi Bond’s specialty products that are capable of passing this test are also employed in high-end optical and electro-optical applications.

Test Method:

This uncomplicated test begins by first conditioning the sample in a 50% relative humidity chamber for 24 hours. The sample is then placed in a vacuum test chamber at 125°C and a minimum vacuum of 5 × 10-5 torr. The volatiles outgassing the sample are collected on a collector plate cooled at 25°C during this time. The sample and the condensate are then weighed to determine the following:

CVCM: The amount of collected volatile condensable materials (CVCM) on the collector plate.

TML: The amount of total mass loss (TML) by the sample

WVR: The amount of water vapor regained (WVR) by the sample

The material is said to pass or fail the test based on the following conditions:

CVCM < 0.1% and TML < 1% - Pass

CVCM < 0.1% and TML > 1% – Pass if TML – WVR <1%

CVCM > 0.1% or TML – WVR > 1% – FailPOPULAR PRODUCTS

Request a Quote Supplied by Kohesi Bond -

One Component Epoxy Systems

ONE COMPONENT EPOXY SYSTEMS

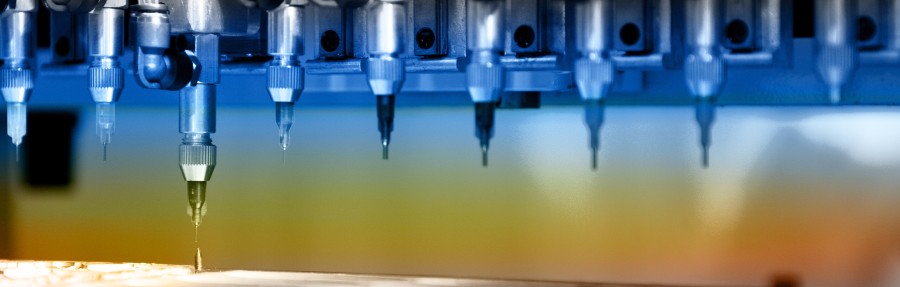

One-part epoxies are special polymer systems where the resin and the curing agent are present in the initial mixture. These systems only start polymerizing on application of appropriate curing conditions, typically heat. Kohesi Bond offers a variety of true single component epoxies that have an unlimited working life at room temperature. They do not require any metering or mixing, thus offering high yield and less waste. Our industry ready, no-mix systems are available in varying performance and curing properties. These products can be customized and packaged to meet your specific requirements.

POPULAR PRODUCTS

Request a Quote Supplied by Kohesi Bond -

TWO COMPONENT EPOXY SYSTEMS

TWO COMPONENT EPOXY SYSTEMS

Two-part epoxies are special polymer systems where the resin and the curing agent are stored in separate containers. The two components (commonly referred to as Part A and Part B) are required to be mixed in the specified mixing ratio. After mixing, the polymerization occurs readily at ambient temperatures or at elevated temperatures for faster cures. Kohesi Bond offers a wide range of two component epoxies with varying working lives and curing properties. The most significant advantage of these products is their ability to cure at room temperature, thus offering an array of performance properties for applications where adding heat for curing is not feasible. Our products can be customised and packaged to meet your specific requirements. Specialty packaging is also available for automated metering and mixing of the two parts, offering ease of use and higher yields.

POPULAR PRODUCTS

Request a Quote Supplied by Kohesi Bond