mk Expands its range of Pallet Systems to include an Indexing Chain Conveyor System

15 March 2019mk Expands its range of Pallet Systems to include an Indexing Chain Conveyor System

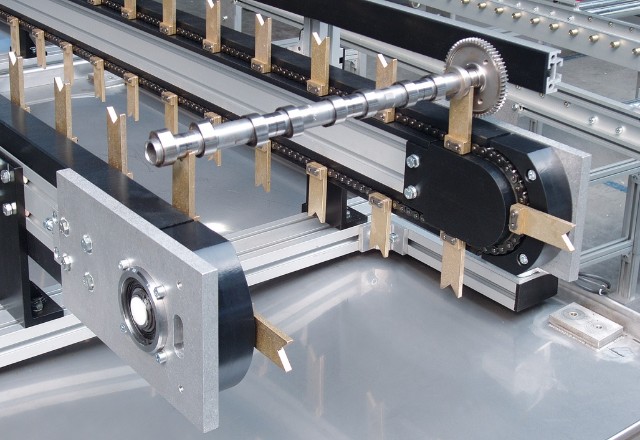

The TKU 2040 indexing chain conveyor system expands mk’s portfolio of pallet systems. It makes cycled supply and interlinking possible, for example in the machine tool and plastics industry as well as in the automotive industry.

The TKU 2040 is especially well suited for defined, position-oriented supply and removal as well as for interlinking machining centres. The system’s timing can be individually configured to a fixed cycle.

The TKU 2040 is based on the mk profile system and is modularly constructed, compact, flexible and extremely robust. It is constructed from a timing chain conveyor with 2 roller chains, which permits a total load of up to 700 kg. The conveyor body consists of two profile sections with gliding assemblies for the chain and the workpiece fixtures. It is available in designs with a predefined width or with an adjustable width. The adjustable width makes it possible to use with workpieces of different sizes.

According to the specific requirements, the workpiece fixtures can be prisms made out of either polyoxymethylene (POM) or brass, which are optimal for holding round work pieces. Alternatively, profile pallets can be individually equipped with customer-supplied workpiece fixtures.

In addition to modules such as fixed and adjustable conveyor bodies, pallets, adjustment units, drives, tails and different types of frames, protective device guards, a drip pan and an automatic lubrication station are also available.

Key features of the TKU 2040 include:

- Load capacity of up to 700 kg

- Permits loads of 6/10 kg (prism) and up to 20 kg (profile pallet) per workpiece

- Compact construction

- Flexible modular design

- Widths between 195 mm and 1500 mm on adjustable models

- Direct drive reduces maintenance and wear

- Conveyor speed up to 18 m/min

- Repeatability of +/- 1 mm possible

To find out more about this and the full range of conveyors manufactured by mk visit www.mkprofiles.co.uk or call (01949) 823751.