RSA Cutting Technologies Ltd

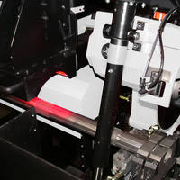

We supply sawing centres for single or multiple cuts, steel or stainless steel parts or non-ferrous metals. Our sawing centres are provided with short set-up times, easy operation, high precision and high economic efficiency. They can be smoothly integrated with all subsequent steps in processes such as deburring, chamfering, measuring, washing and stacking.

Filter products and services

-

Aluminium Extrusion Deburring Machines

Please contact RSA Cutting Systems Ltd for further information on our range of products and services including Aluminium Extrusion Deburring Machines.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Deburring

Increasing cost pressures and increasing demands on quality and precision processing have shaped modern manufacturing. The use of optimal deburring systems is a deciding factor in achieving the desired quality and still reducing the costs per piece. RASAPLAN deburring systems stand for maximum flexibility at minimum costs. They are based on our holistic know how as manufacturers of machines and technical high performance brushes for deburring and assure reliable and reproducible deburring at costs per piece that lie in thousandths of a cent range. Our RASAPLAN systems can be linked to any machine of other brands or can be used as a stand-alone machine.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Deburring Brushes

Burrs are sharp edges that occurred during a processing or manufacturing process. RSA produces different manual and automatic deburring machines, as well as the matching brushes for deburring pipes and profiles.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Deburring Machines

Deburring tubes, bars, profiles and sheets after cutting is a must. But only the right system will provide low cost, reliable and immaculate deburring with the machine design and the high performance brushes being optimally adapted to the properties of the workpiece and the quality of the material. RSA as the manufacturer of the machines and high performance brushes combines is the only company to combine both scopes. You the user benefit, as this complete system allows you to always have reproducible, perfect results. Discover the advantages RSA deburring systems have to offer!Request a Quote Supplied by RSA Cutting Technologies Ltd -

Deburring machines

The deburring of tubes and bars after the cutting is a must. But only the appropriate system allows a low cost, safe and effcient deburring. For this purpose HÄBERLE® offers various deburring machines for the deburring and chamfering of round tubes and round bars made of steel, stainless steel, non-ferrous metals, aluminium and plastics.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASA DUO

The RASA DUO one-ups the RASA MONO in universality. Its two machining stations makes it the right equipment wherever deburring jobs are constantly changing. By combining high performance brushes for deburring on the first and, using the example of an abrasive block, on the second drive station centre waste or an oxide layer can be ground off and the workpiece then deburred without any lost time. RASA DUO guarantees reliable deburring of front faces and long sides on tubes, hollow profiles, solid material profiles and sheets of steel, stainless steel and non-ferrous metals. Guaranteed evenly deburred workpieces for the entire life of the deburring tool. The clearance between the high performance brush and workpieces rest is variable and compensates for brush wear. RASA DUO is suitable for tubes and profiles with diameters of up to 90 mm and lengths of 100 mm and up. The optional short tube deburring attachment KRV for workpieces shorter than 100 mm. Templates for round tubes, square tubes and other shaped profiles can quickly be changed. Changing brushes takes less than a minute. The deburring process doesn't depend on the workpiece shape: manually turning the workpiece by 360° will simultaneously deburr the inner and outer edges of hollow profiles without producing secondary burs or altering the size.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASA DUO deburring machine

The RASA DUO one-ups the RASA MONO in universality. Its two machining stations makes it the right equipment wherever deburring jobs are constantly changing. By combining high performance brushes for deburring on the first and, using the example of an abrasive block, on the second drive station centre waste or an oxide layer can be ground off and the workpiece then deburred without any lost time. RASA DUO guarantees reliable deburring of front faces and long sides on tubes, hollow profiles, solid material profiles and sheets of steel, stainless steel and non-ferrous metals. Guaranteed evenly deburred workpieces for the entire life of the deburring tool. The clearance between the high performance brush and workpieces rest is variable and compensates for brush wear. RASA DUO is suitable for tubes and profiles with diameters of up to 90 mm and lengths of 100 mm and up. The optional short tube deburring attachment KRV for workpieces shorter than 100 mm. Templates for round tubes, square tubes and other shaped profiles can quickly be changed. Changing brushes takes less than a minute. The deburring process doesn't depend on the workpiece shape: manually turning the workpiece by 360° will simultaneously deburr the inner and outer edges of hollow profiles without producing secondary burs or altering the size.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASAMAT Automat

The RASAMAT Automat deburrs both workpiece faces simultaneously. A conveyor feeds the workpiece. The RASAMAT Automat is a feed-through system with top output volumes of 1,800 pieces per hour. workpiece sizes can be switched within seconds, also automated - analogue the parameters entered on the control console or using the workpieces data copied from another machine, for example a saw. No additional set-up required. Amortisation times of six months aren't uncommon with the RASAMAT Automat. Investment costs are manageable, engineering costs for integrating it into the existing production low, and the increase in production three times that of a semi-automated solution. The RASAMAT Automat is usually linked with an upstream separation system. Additional machining modules can be connected after deburring, for example workpiece length measurement or online cleaning.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASAMAT automat extrusion deburring

The RASAMAT Automat deburrs both workpiece faces simultaneously. A conveyor feeds the workpiece. The RASAMAT Automat is a feed-through system with top output volumes of 1,800 pieces per hour. workpiece sizes can be switched within seconds, also automated - analogue the parameters entered on the control console or using the workpieces data copied from another machine, for example a saw. No additional set-up required. Amortisation times of six months aren't uncommon with the RASAMAT Automat. Investment costs are manageable, engineering costs for integrating it into the existing production low, and the increase in production three times that of a semi-automated solution. The RASAMAT Automat is usually linked with an upstream separation system. Additional machining modules can be connected after deburring, for example workpiece length measurement or online cleaning.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASAMAX DUO

RASAMAX DUO was developed specifically for quickly and reliably deburring straight sheets. The deburring machine features two counter-rotating deburring brushes on two offset levels. Using this concept the top and lower edge of the sheet are deburred simultaneously in just one cycle. That means up to 50 % time savings compared to other methods! The workpiece is simply placed on the roller table and guided along the lay-on edge and the high performance brushes. Razor-sharp sheet edges - e.g. caused by shearing - are safely rounded off within seconds. Yet it causes no secondary burrs or alter the size. The use of plastic bonded high performance brushes allows straight sheet edges to be deburred without damaging the surface. RASAMAX DUO is suitable for deburring single pieces and small batches, and the robust construction is designed for continuous operation.Request a Quote Supplied by RSA Cutting Technologies Ltd