RSA Cutting Technologies Ltd

We supply sawing centres for single or multiple cuts, steel or stainless steel parts or non-ferrous metals. Our sawing centres are provided with short set-up times, easy operation, high precision and high economic efficiency. They can be smoothly integrated with all subsequent steps in processes such as deburring, chamfering, measuring, washing and stacking.

Filter products and services

-

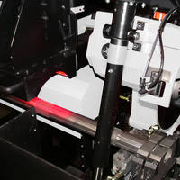

RASACUT SK

The RASACUT SK saw was developed to separate short work pieces starting from 20 mm length with high precision and output. It is designed for fixed lengths of 20 to 150 mm. The RASACUT SK is a compact short tube saw for small and large series in three shift operation. In contrast to our other models, it is often used to cut bulk material. Areas of application are the manufacture of sleeves and spacer bushes or the manufacture of rubber-metal connectors, e.g. as stabilisers for chassis. With short dimensions, tube handling and smooth, reproducible deburring constitute special challenges. RASACUT SK is a reliable solution that improves work process and quality- not just for sawing, but also for deburring.Request a Quote Supplied by RSA Cutting Technologies Ltd -

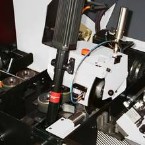

RASACUT TC

Thin-walled tubes are very critical in the manufacture of fixed lengths. If an unfavourable ratio of diameter to wall thickness is thrown into the mix, a high reject rate is practically guaranteed. For that reason users tend to use laser cutting machines when clean, deformation-free cuts are needed for thin-walled tubes. Admittedly that demands a high investment- but it doesn't need to be that way. Because the RASACUT TC presents a cost effective alternative to laser cutting providing the same quality. This means: Cost savings from the start, without having to compromise on quality. RASACUT TC is a high performance single cut saw for thin-walled tubes starting at 0.4 mm wall thickness, especially for delicate work pieces, such as you find in the automotive, medical technology and aerospace industries or in production of heat exchangers. RASACUT TC is a high performance single cut saw for thin-walled tubes starting at 0.4 mm wall thickness, especially for delicateTo keep from deforming the tube when the saw blade makes contact, the saw uses low forward force at this tricky point. So that this does not detract from total output, the tube is then cut at high speed. When the saw blade then exits, the forward force is slowed again so that burr formation is reduced so much along the edge that the burring can be safely removed with high performance brushes. work pieces, such as you find in the automotive, medical technology and aerospace industries or in production of heat exchangers. The precisely calibrated forward feed is realised using a servo axis. The speeds are calculated independently by the control based on the work piece parameters. Work piece clamping is especially important. Here it is possible to securely clamp even fixed lengths with an unfavourable diameter-to-wall-thickness ratio without deforming the work piece.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASACUT XS

RASACUT XS is the alternative to multiple or bundle cut saws in the manufacture of large-scale batches with diameters of 6 to 50 mm. With the single-cut saw RASACUT XS, you improve your quality, reduce unit costs and guarantee high part quality. Areas of application include fuel and brake lines or visible components such as head rest supports. An essential advantage lies fully automatic processing sequence. Through the consistent reduction of cycle times, the RASACUT XS achieves output levels in single cut operation that are just as high as multiple or bundle-cut saws, depending on the dimension range, even higher! Do you need a multiple cut saw for small diameters? Then learn about the RASACUT MXS!Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASACUT XXL

The sawing centre RASACUT XXL was developed especially for cutting tubes and solid bars up to 170 mm. With that you achieve a reduction in sawing time by up to 90% compared to modern bandsaws along with improved quality of cut surface in terms of both squareness and surface roughness. The single-cut saw guarantees high output with optimal part and cut surface quality as well as precisely weighted cuts with 100 percent control optional. RASACUT XXL is optimally suited for use in the automotive, forging and steel trade industries.Request a Quote Supplied by RSA Cutting Technologies Ltd -

S 225 Saw

The S 225 is a portable, compact saw for small sections, tubes and solid bars made of steel, stainless steel and non-ferrous metal designed for 90° cuts without burr.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Saw blades

We manufacture our own saw blades, because only then we can be sure that our machines bring the best results for you. This is professionalism with a system: As a saw blade manufacturer, we have extensive knowledge of the optimum adaptation of tooth geometries to workpiece and material. In parallel, as a manufacturer of sawing machines, we determine the optimum forward feed and cutting speed. The result is maximum performance and quality.Request a Quote Supplied by RSA Cutting Technologies Ltd -

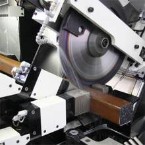

Saw blades

We produce our own saw blades, because this is the only way we can be sure that our machines provide the ideal results for you. This is professionalism with a system: As saw blade manufacturer we possess in-depth knowledge about the ideal adaptation of tooth geometries on work pieces and materials. As a producer of sawing machines we determine ideal feed and cutting speeds in parallel. The result is maximum performance and quality. Our brand RASABLADE stands for extremely long lifetimes and utmost cutting precision. Elaborate manufacturing procedures guarantee consistent high quality and ensure reproducible cutting results. Standard dimensions are available ex factory, special productions in juts a few days.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Saw blades RASABLADE

We produce our own saw blades, because this is the only way we can be sure that our machines provide the ideal results for you. This is professionalism with a system: As saw blade manufacturer we possess in-depth knowledge about the ideal adaptation of tooth geometries on work pieces and materials. As a producer of sawing machines we determine ideal feed and cutting speeds in parallel. The result is maximum performance and quality. Our brand RASABLADE stands for extremely long lifetimes and utmost cutting precision. Elaborate manufacturing procedures guarantee consistent high quality and ensure reproducible cutting results. Standard dimensions are available ex factory, special productions in juts a few days.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Sawing Centres

Please contact RSA Cutting Systems Ltd for further information on our range of products and services including Sawing Centres.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Sawing Machines Aluminium

Please contact RSA Cutting Systems Ltd for further information on our range of products and services including Sawing Machines Aluminium.Request a Quote Supplied by RSA Cutting Technologies Ltd