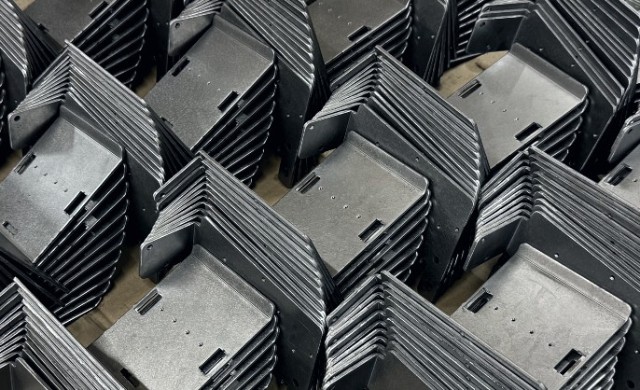

Bespoke sheet metal brackets manufactured in the UK

22 March 2024Custom sheet metal brackets offer a multitude of advantages when it comes to industrial lighting applications, providing tailored solutions that enhance functionality, durability, and aesthetics. By partnering with a reputable manufacturer like V and F Sheet Metal, companies can unlock a range of benefits that cater specifically to their unique requirements.

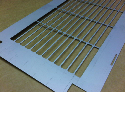

One key advantage of designing custom sheet metal brackets is optimized fit and compatibility. Industrial lighting fixtures often require precise positioning and alignment to ensure efficient illumination. Off-the-shelf brackets may not offer the exact dimensions needed, leading to compromises in performance and stability. However, with custom brackets, manufacturers can tailor the design to perfectly accommodate the specific dimensions and mounting requirements of their lighting fixtures. This ensures a seamless integration and maximizes the effectiveness of the lighting system.

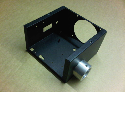

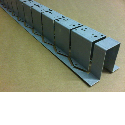

Moreover, custom brackets allow for the incorporation of additional features and functionalities that enhance performance and longevity. For instance, reinforcement ribs, gussets, or specialized mounting points can be strategically integrated into the design to improve structural integrity and withstand harsh environmental conditions. This customization ensures that the brackets can endure heavy loads, vibrations, and exposure to elements, prolonging the lifespan of the lighting fixtures and reducing maintenance costs.

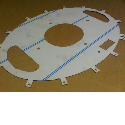

Aesthetics also play a crucial role in industrial environments, where lighting fixtures often serve as both functional elements and design accents. Custom sheet metal brackets offer the flexibility to achieve the desired aesthetic appeal, whether it's through unique shapes, finishes, or branding elements. By aligning the bracket design with the overall design language of the facility or product line, manufacturers can create visually cohesive and appealing lighting solutions that enhance the overall ambiance of the space.

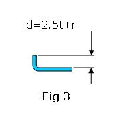

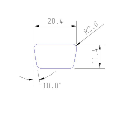

V and F Sheet Metal, with its expertise in custom sheet metal fabrication, exemplifies the capabilities needed to realize these advantages. Their gallery showcases a diverse range of custom bracket designs, highlighting the versatility and precision achievable through bespoke fabrication. From simple L-shaped brackets to complex multi-angle configurations, the examples demonstrate how custom brackets can address varied application needs while maintaining high standards of quality and craftsmanship. Collaborating with such a specialist enables companies to harness the full potential of custom sheet metal brackets for their industrial lighting projects, achieving superior performance, durability, and aesthetics.