BIG EFFORT FROM A SMALL CNC PRESS BRAKE

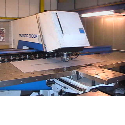

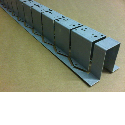

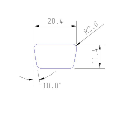

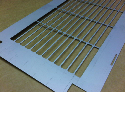

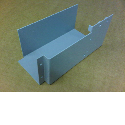

18 March 2016Just because we use our two Trumpf 7036 CNC press brakes for bending small parts doesn’t mean they cannot help out when folding larger sections. Right up to 1M long is no problem for these great little machines and with 36 tons force they have more than enough force to fold up these zintec chassis sections. This image clearly shows the 1M tooling across the top and bottom of the press with plenty of room to access the machine for quick production bending speeds.

3D graphics and a touch sensitive screen allows the shop floor machine setters to write CNC programs really quickly, store them away on our company server and recall them for repeat batches of work whenever needed. These machines are a big part of what we do here at V and F Sheet Metal with the majority of our bending work being under 1M long but when parts are over 1M long we have our new Safan e-Brake 3M 100 ton machine to take over. This new machine can obviously bend items under 1M as well to offer a great bending service to our customers. Along with a 2.5M long CNC press brake and 2 smaller 600mm machines we have all sheet metal bending needs covered under one roof.

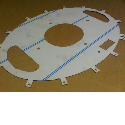

The sheet metal blanks in this case have been manufactured by CNC punching but they could just as easily have been laser cut and they would have bent up just the same. Having the ability to provide the machine with accurate blanks batch after batch is vital to not only ensure the accuracy of the final folded parts but in enabling quick set up of the machine tools with minimal adjustments needed before production bending can start.

Whether you have a sheet metal working project than is just a few mm across or up to 3M long we can help you here at V and F Sheet Metal, please give us a call at 0.1489 57786.