CNC PUNCHED SHEET METAL WORK

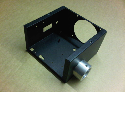

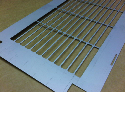

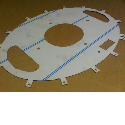

18 March 2016Nice range of simple aluminium electronic front panels for professional audio equipment. With the large range of CNC punch tooling we have here most shapes and sizes of cut-out can be catered for without the need to purchase special CNC tooling. We have a list of all the CNC punch press tooling that you can specify when creating a new sheet metal design to make it easy for you to save money. If you are not sure you only have to call us and we will be happy to advise you on the best set of tooling to do the job. These front panels were CNC punched and had all external punched edges de-burred before they were wet spray painted and shipped. Sets of similar parts were all CNC punched on the same sheets to save material costs and keep the parts together in production.

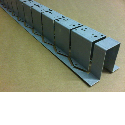

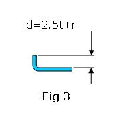

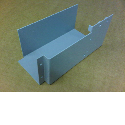

Small aluminium clamping bars used in electronics equipment. These sheet metal bars were CNC punched on our Trumpf 200 CNC punch press using standard tooling. The parts were punched down through a die and collected from the machine with no corner holding tags. The parts were then barrel de-burred to remove all the sharp edges and finally, using our Haeger inserter, had their flush head studs pressed in place. The Haeger inserter can also be used to insert hank bushes, self clinch nuts, tank bushes, stand-offs and special purpose fasteners.

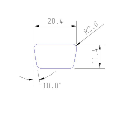

A simple 0.7mm thick zintec coated mild steel bracket blank produced on one of our CNC punch presses. The radiused corners being produce with our R2, R3, R4 and R5 combination punch tool. These parts are typical of the small sheet metal work that we CNC punch out all the time here at V and F Sheet Metal. If we don’t have quite the right tooling on the rack we can always look to laser cut the parts, so between both manufacturing processes we can cover all your sheet metal blank needs in ferrous and non-ferrous materials.

If you are looking for a supplier of sheet metal work then please give us a call on 01489 577786 or send your drawings to sales@vandf.co.uk and we will be happy to review them and produce some prices for manufacturing.