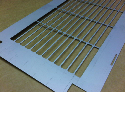

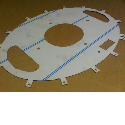

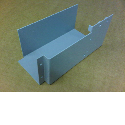

Custom made sheet metal brackets made to your designs - ask for details today

28 November 2023Investing in custom-made sheet metal brackets offers a range of advantages that play a pivotal role in optimizing performance, structural integrity, and overall efficiency across various industries. One of the primary benefits is the precise tailoring of brackets to meet specific requirements. Customization allows manufacturers to design brackets that perfectly fit the dimensions and specifications of the components they are intended to support. This precision ensures optimal alignment and functionality, reducing the risk of errors or malfunctions in the assembly.

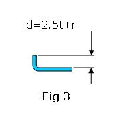

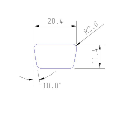

Furthermore, custom sheet metal brackets can be engineered to address unique challenges and accommodate specialized applications. Whether it's adapting to tight spaces, unusual angles, or specific load-bearing requirements, the flexibility of customization ensures that the brackets are designed to meet the exact needs of the project. This adaptability is particularly valuable in industries where standard, off-the-shelf brackets may not provide an adequate solution.

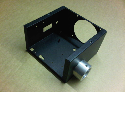

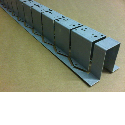

The material strength and durability of sheet metal contribute significantly to the robustness of custom brackets. Manufacturers can choose from a variety of high-quality materials, such as stainless steel or aluminum, depending on the application's demands. This ensures that the brackets not only provide reliable support but also withstand environmental factors like corrosion, moisture, and temperature variations, enhancing the longevity of the entire system.

https://www.vandf.co.uk/gallery/bracket-angle-gallery/

Custom sheet metal brackets also contribute to cost-effectiveness by minimizing material waste. The ability to design brackets with precise dimensions reduces the need for excess material, optimizing resource utilization and minimizing production costs. This efficiency is not only environmentally friendly but also reflects positively on the overall economic feasibility of the manufacturing process.

In conclusion, the advantages of purchasing custom-made sheet metal brackets extend beyond simple customization. They encompass precision, adaptability, material strength, and cost-effectiveness, making them a valuable investment for industries that prioritize performance, durability, and efficiency in their applications.