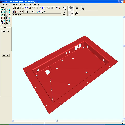

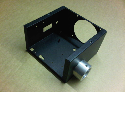

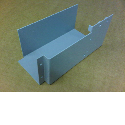

Custom sheet metal brackets manufactured to your own designs

6 December 2023https://www.vandf.co.uk/gallery/bracket-angle-gallery/

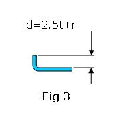

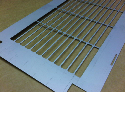

Bespoke sheet metal brackets are integral to the electronics industry, playing a critical role in the design and functionality of various electronic components. One prominent application is within 19" rack mount systems, where customized brackets are employed for securing and organizing electronic equipment.

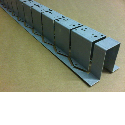

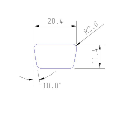

In the realm of 19" rack mount systems, which are standard in data centers, telecommunication facilities, and audio/video setups, bespoke sheet metal brackets serve as the backbone for mounting servers, switches, and other critical hardware. These brackets are tailored to the specific dimensions and requirements of the equipment, ensuring a snug fit and optimal functionality. Precision is paramount in this context, as even the slightest deviation can compromise the integrity of the entire system.

The versatility of bespoke sheet metal brackets allows engineers to address specific challenges posed by unique electronic configurations. Whether accommodating non-standard equipment dimensions or integrating additional features like cable management, engineers can tailor brackets to meet the exact needs of the application. This level of customization enhances the efficiency of rack systems, streamlining installations and maintenance.

Furthermore, bespoke brackets contribute to the structural integrity and durability of 19" rack mount systems. By leveraging high-quality materials and precision manufacturing techniques, engineers can ensure that these brackets provide robust support, minimizing the risk of equipment damage due to vibrations or shocks.

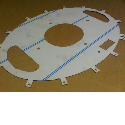

The electronics industry's rapid evolution demands adaptability, and bespoke sheet metal brackets offer a flexible solution. As technologies advance and new electronic devices emerge, engineers can quickly design and produce custom brackets to accommodate these innovations. This adaptability extends the lifespan of 19" rack mount systems, allowing them to remain relevant and functional amid changing technological landscapes.

In conclusion, bespoke sheet metal brackets are indispensable in the electronics industry, especially within 19" rack mount systems. Their role in customization, structural support, and adaptability exemplifies their significance in ensuring the seamless integration and performance of electronic components in various applications.