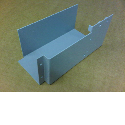

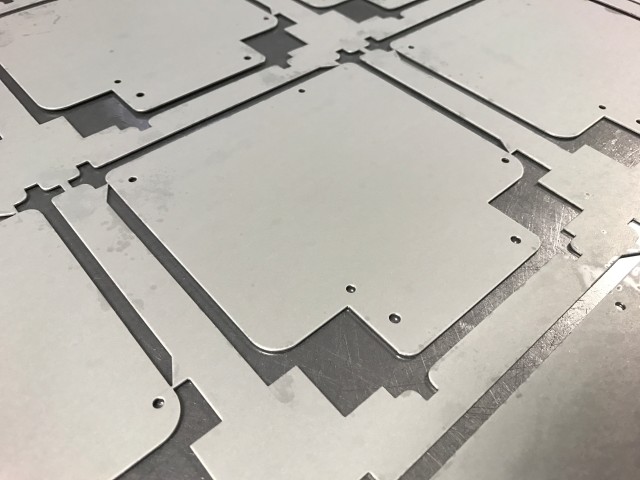

Designing bespoke sheet metal work for electronics enclosures

21 December 2023As an electro-mechanical design engineer, incorporating bespoke sheet metal work into your designs can yield substantial cost savings and enhance overall project efficiency. Customized sheet metal solutions, particularly in the design of enclosures, offer numerous advantages that contribute to both financial and operational benefits.

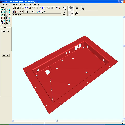

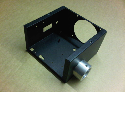

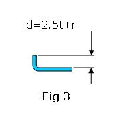

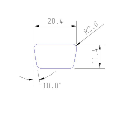

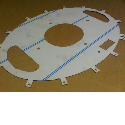

Firstly, bespoke sheet metal work allows for precise tailoring of enclosures to fit the exact specifications of the equipment they house. This eliminates unnecessary material waste, as standardized off-the-shelf enclosures often result in excess materials that drive up costs. By optimizing the dimensions and features of the enclosure to the specific requirements of the electronics or machinery, you can significantly reduce material expenses.

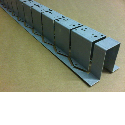

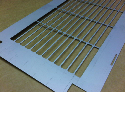

Moreover, customization enables the integration of features such as cable management, cooling systems, and mounting options directly into the sheet metal design. This not only enhances the functionality of the enclosure but also reduces the need for additional components or modifications, streamlining the assembly process. Consequently, labor costs associated with assembly and installation decrease, contributing to overall project savings.

https://www.vandf.co.uk/blog/sheet-metal-in-electronics-precision-enclosures-and-cases/

Additionally, bespoke sheet metal work allows for the use of cost-effective yet durable materials, tailored precisely to the application. This ensures that the final product meets performance requirements without unnecessary expenditures on premium materials.

In summary, investing in bespoke sheet metal work for custom enclosures can result in substantial cost savings by minimizing material waste, optimizing functionality, and reducing labor expenses. The tailored approach not only enhances the efficiency of the design process but also ensures that the final product aligns perfectly with the specific needs of the electro-mechanical system.