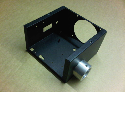

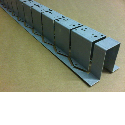

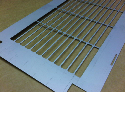

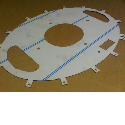

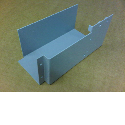

Laser cut components with a protective plastic film

27 September 2018Laser cut stainless steel

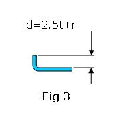

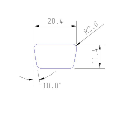

This week our Trumpf 3030 3KW fiber laser has been going great guns, hardly stopping between jobs! The latest interesting project involved producing a batch of 300 laser cut brackets using stainless steel of 2mm gauge with a 4 thou plastic fiber laser coating.

We are able to offer you a complete laser cutting service from 3D modelling, CAD/CAM program development, laser cutting and down stream production processes. Using Radan 2017 sheet metal CAD/CAM software we take your 3D data in the form of STEP or SAT files. 2D drawings can also be acceptable of PDF files and we will calculate the correct developed blank sizes for you. Using advanced nesting algorithms we can experiment with different nesting patterns to produce the most parts from any given sheet. This technique helps to reduce costs at the quoting stage and speeds up production cutting times.

If you have a project that needs some input from a friendly sheet metal company then we are here to help. We can look at your designs and suggest areas that can be improved with a view to saving you money. Always a great start! Just send us your drawings to sales@vandf.co.uk and we will be happy to take a look for you.

Would you like to see more images of laser cut components to give you some ideas for your design? Take a look here: Pinterest Board We have many examples of our work on our Pinterest Boards and gallery pages within our website.

If you are interested in a more detailed description of the production of this component, please read our blog post :

http://www.vandf.co.uk/blog/laser-cut-stainless-steel-plates-with-a-protective-plastic-film/