Looking for a flexible sheet metal working company to support your manufacturing needs

29 November 2023https://www.vandf.co.uk/tooling/what-is-cnc-bending/

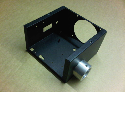

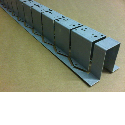

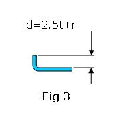

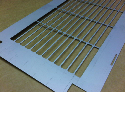

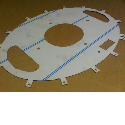

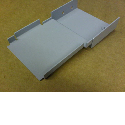

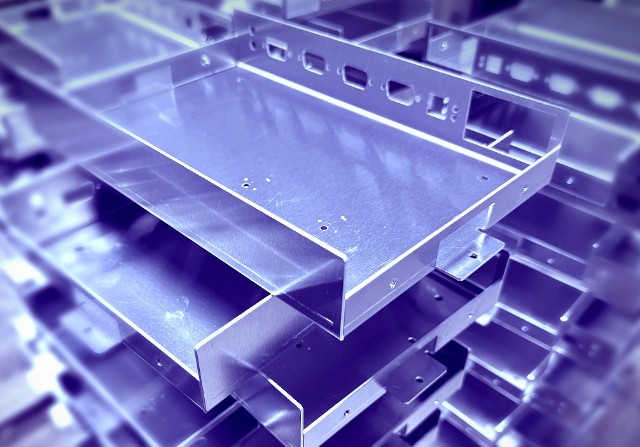

Folded sheet metal components stand as a great example of precision engineering and versatility in modern manufacturing. This technique involves manipulating flat sheets of metal, often aluminum or steel, into three-dimensional forms through a sequence of carefully executed bends. The result is a seamless, structurally sound component that finds applications across various industries.

One notable advantage of folded sheet metal components is their strength-to-weight ratio. The folding process increases the rigidity of the material, providing robustness without unnecessary added weight. This is particularly crucial in industries where lightweight yet durable components are imperative for efficiency and performance.

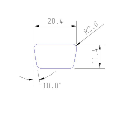

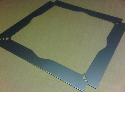

Furthermore, the flexibility in design is a key attribute. The ability to create complex geometries and intricate shapes allows for the production of custom components tailored to specific needs. This adaptability is especially beneficial in industries such as aerospace, automotive, and electronics, where unique and space-efficient designs are often paramount.

The precision achieved through modern CNC (Computer Numerical Control) technology enhances the accuracy of each fold, ensuring consistency and repeatability in mass production. This not only streamlines manufacturing processes but also contributes to the overall quality and reliability of the final product.

In conclusion, folded sheet metal components exemplify the marriage of form and function in engineering. Their strength, lightweight nature, and design flexibility make them a cornerstone in the production of diverse and sophisticated components across industries, showcasing the prowess of modern manufacturing techniques.