Manufacturing sheet metal housings to your own designs

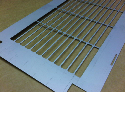

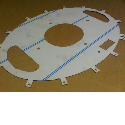

15 November 2023Manufacturing sheet metal housings is a complex and precise process that requires a harmonious blend of engineering expertise and cutting-edge technology. The journey begins with the careful selection of sheet metal, a decision influenced by factors such as the intended application, environmental conditions, and desired durability. Common choices include steel and aluminum, prized for their strength and formability. The selected metal undergoes a meticulous transformation through a series of steps, starting with cutting. Traditional methods like shearing or advanced techniques such as laser cutting define the initial shape of the housing. This phase is critical as it lays the foundation for the housing's structural integrity and functionality.

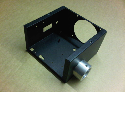

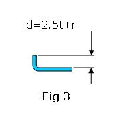

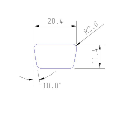

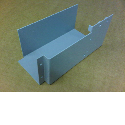

Following the cut, the sheet metal moves into the forming stage. This involves shaping the metal into the desired configuration through processes like bending, folding, or stamping. Precision is paramount during this stage to ensure uniformity and consistency in the final product. Welding may come into play, joining various components together to create a seamless, unified structure. The welding process requires a high level of skill to achieve strong and durable bonds between metal parts.

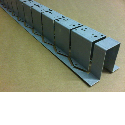

Surface finishing is the next crucial step in manufacturing sheet metal housings. Various treatments, such as powder coating or galvanization, are applied to enhance both the aesthetic appeal and the protective qualities of the housing. These treatments not only contribute to the visual aesthetics of the final product but also provide a protective layer, preventing corrosion and extending the lifespan of the housing. The choice of surface finish can be influenced by the intended environment of use, with considerations for factors like humidity, temperature, and exposure to corrosive elements.

Innovations in manufacturing techniques have played a significant role in shaping the landscape of sheet metal housing production. Advanced technologies, such as computer numerical control (CNC) machining, have elevated precision to new levels, allowing for intricate designs and complex geometries. Automation has streamlined the manufacturing process, improving efficiency and reducing the margin of error. Additionally, there is a growing emphasis on sustainability in the manufacturing industry, leading to the exploration of eco-friendly materials and processes in the production of sheet metal housings.

Sheet metal housings find application in a wide array of industries, from electronics and automotive to telecommunications and beyond. Their versatility and durability make them indispensable for protecting sensitive components and machinery, ensuring the safe and efficient operation of various devices. As technology continues to advance, the manufacturing of sheet metal housings will undoubtedly witness further innovations, pushing the boundaries of what is possible and setting new standards for quality and efficiency in the world of industrial design.

Contact V and F Sheet Metal at http://www.vandf.co.uk if you need a quote to manufacture your sheet metal housings.