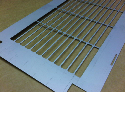

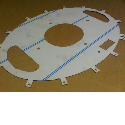

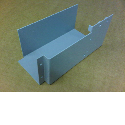

Precision sheet metal work manufactured in the UK

23 November 2023https://www.vandf.co.uk/blog/precision-sheet-metal-work-manufactured-in-the-uk/

Precision sheet metal work offers numerous advantages, making it a preferred choice in various industries. Firstly, precision is inherent in the process, ensuring accurate and consistent fabrication of complex components. This accuracy leads to enhanced product quality and performance, critical for industries like aerospace, electronics, and automotive.

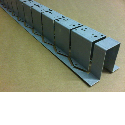

The versatility of precision sheet metal work is another key advantage. It accommodates a wide range of materials, including steel, aluminum, and copper, allowing manufacturers to select the most suitable material for their specific application. This flexibility extends to the thickness of materials, enabling the production of both thin and thick gauges, meeting diverse design requirements.

Cost-effectiveness is a significant benefit. Precision sheet metal fabrication reduces material waste through efficient nesting and optimization techniques. This not only lowers raw material costs but also minimizes environmental impact. Additionally, the use of Computer Numerical Control (CNC) machines enhances efficiency and reduces labor costs by automating the fabrication process.

The speed of production is noteworthy. Precision sheet metal work, especially when coupled with advanced technologies, allows for rapid prototyping and quick turnaround times. This agility is crucial in industries with dynamic market demands, providing a competitive edge.

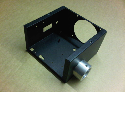

The durability of precision sheet metal components is another advantage. The fabrication process enhances material strength and structural integrity, resulting in products with a longer lifespan and greater resistance to wear and tear. This durability is particularly valuable in applications where components are subjected to harsh environmental conditions or heavy usage.

Furthermore, precision sheet metal work facilitates complex designs and intricate detailing, allowing manufacturers to create highly customized components. This customization is vital in industries where unique specifications are required, such as in medical devices or specialized machinery.

In summary, precision sheet metal work offers advantages in terms of accuracy, versatility, cost-effectiveness, speed of production, durability, and customization. These factors collectively contribute to its widespread adoption across various industries, meeting the demands of modern manufacturing and engineering.