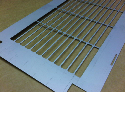

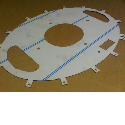

Sheet metal manufacture of bespoke components and assemblies produced in the UK

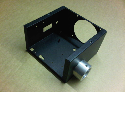

23 April 2024Sheet metal manufacture is a critical process in creating bespoke components and assemblies for various industries, including automotive, aerospace, electronics, and construction. This process involves cutting, bending, forming, and assembling metal sheets to create complex parts tailored to specific requirements. By employing advanced techniques and machinery, manufacturers can produce high-quality components that meet exact specifications. Not only does sheet metal manufacture provide the versatility to create intricate designs, but it also allows for cost-effective production and rapid turnaround times.

One significant advantage of sheet metal manufacture is its flexibility in design. With advanced computer-aided design (CAD) software, engineers can create detailed models of components and assemblies. These designs can be easily modified and adjusted to meet specific needs, allowing for a high degree of customization. This flexibility ensures that manufacturers can adapt to changing demands, making it ideal for producing bespoke components with unique shapes and sizes. Moreover, with the capability to quickly prototype and test designs, the development process becomes more efficient.

Additionally, sheet metal manufacture offers considerable cost savings. By utilizing sheet metal fabrication techniques such as laser cutting and CNC bending, manufacturers can reduce material waste and streamline the production process. This efficiency translates to lower production costs, making it an attractive option for businesses seeking to minimize expenses. Furthermore, the durability and strength of sheet metal components contribute to a longer lifespan, reducing the need for frequent replacements and further lowering long-term costs.

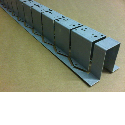

Another advantage of sheet metal manufacture is its scalability. Whether a project requires a single custom part or large-scale production, manufacturers can adjust their processes to meet the demand. This scalability is particularly beneficial for businesses that experience fluctuations in order volume or require quick turnaround times for their projects. With automated machinery and streamlined workflows, manufacturers can maintain consistent quality while scaling production to meet customer needs.

In conclusion, sheet metal manufacture is a versatile and cost-effective process that offers numerous benefits for creating bespoke components and assemblies. The flexibility in design, cost savings, and scalability make it an ideal choice for a wide range of industries. With advanced technology and skilled engineers, manufacturers can produce high-quality parts that meet specific requirements, ensuring that businesses can stay competitive in a rapidly evolving market. As sheet metal manufacture continues to evolve, its role in custom component production will only become more significant, driving innovation and efficiency across industries.

https://www.vandf.co.uk/blog/sheet-metal-manufacture-of-bespoke-components-and-assemblies/