Sheet Metal Work From V and F Sheet Metal in Hampshire Great Britain

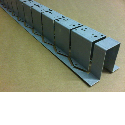

8 October 2018Every day we receive a variety of inquires, some large scale, others smaller. Whether you just need a few sheet metal prototypes for your new design or full production we are here to give you the help you need! We use the latest methods of CNC punching and laser cutting to produce accurate sheet metal blanks. Working with our range of CNC bending machines to produce work from the simplest single angle to complex electronics chassis components. In addition to this we offer in house welding facilities, all in all a comprehensive manufacturing service!

We have an expert team of trained sheet metal workers able to turn their hand to all sorts of projects. From welding aluminium housings, folding stainless steel enclosures, laser cutting brass and copper electrical components. You come up with it and we've seen it before!

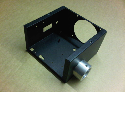

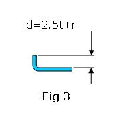

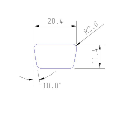

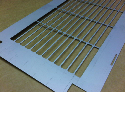

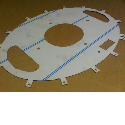

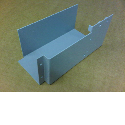

The image shown here is a CNC punched zintec treated mild steel bracket. Using a particularly clever piece of tooling on our Trumpf 3000R we were able to produce the folded flaps at the same time as punching. The Trumpf multi-bend tooling works with a range of materials and thicknesses. It saves a lot of time and produces a very consistent bend.

So it's down to you now. Give us a call today if you have a project and you want some advice and information on prices. We are always happy to look at current parts and offer valuable advice to help save you money. Perhaps we can manufacture your component using a different process which could potentially improve quality and save you some money. Contact us on 01489 577786 or sales@vandf.co.uk.