SHEET METAL WORK MANUFACTURING 2016

1 February 2016Sheet Metal Work Manufacturing 2016

I thought I would start 2016 with a quick round up of the sheet metal work projects that are going through the manufacturing workshop. We have components be manufactured in galvanised mild steel, zintec coated mild steel and plain uncoated mild steel in these images. With a range of sizes, thicknesses, batch volumes and manufacturing methods. The purpose of this blog post is to help highlight the wide range of sheet metal work manufacturing that we can take on for our customers here in the UK and across Europe.

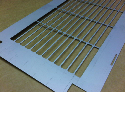

Light fitting galvanised mild steel gear plates

These light fitting electronic equipment gear trays have been manufactured from 0.7mm thick galvanised mild steel sheet. The initial flat blank was produced on our Trumpf CNC punch presses to a CNC program laid out in our Radan software. All the holes and outer profile was CNC punched using standard CNC tooling we already had so there was no tooling cost to the customer. The edges were simply de-burred using a vertical de-burring belt machine within the punching cycle time and then the bends were added on one of our CNC press brakes. This was a large batch of work with several thousand gear trays manufactured on this occasion.

Sheet metal plates made from pre-cut zintec blanks

Sometimes when the volumes are quite high and the format of the sheet metal component that we are manufacturing is simply a square or a rectangle we can remove the need to either laser cut or CNC punch the parts by buying in a pre-cut blank. These blanks are supplied by the material stockist direct from the master material coil as with these 0.7mm thick zintec coated mild steel sections. Again there were several thousand needed on this order and we have a range of tooling die sets that simply pierce out the end profiles and holes. Not only does this speed up the manufacturing of these parts but it frees up laser cutting and CNC punching capacity for more complex parts to be manufactured in our factory. The final operation on these components is to have a curved form pressed into each part along their length on one of our CNC press brakes using a special form tool and then pop riveted to a pre-formed end cap to make up an assembly. It’s just another way of manufacturing sheet metal work and shows the flexibility of manufacturing in the UK.

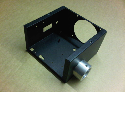

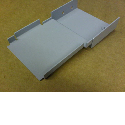

Mild steel wall mounting brackets

Theses wall mounting brackets for fan heaters have been manufactured from 2mm thick CR4 mild steel and will be completed by powder coating RAL9010 white. They have been manufactured by laser cutting from 2M x 1M sheets on our Trumpf 3030 3KW fibre laser using nitrogen form a clean cut which will take a powder coated finish without any difficultly from oxidised edges. The mounting brackets have been pressed up into the shape you can see here with a custom press tool that forms all 6 bends in one go. You can see the classic draw marks along the sides of the mounting brackets where the mild steel has scuffed against the die as it was pressed into the tool on our HMS 55 ton power press. When the are reasonable volumes in each batch and a customer can be confident that they will not be changing their design press tooling can be a useful sheet metal work manufacturing method. If a component will be redesigned regularly or the volumes are smaller then the use of CNC press brakes come into their own with only a quick program change being needed to produce a longer bend of a different angle. As with all these manufacturing process methods you “pays your money and takes your choice”.

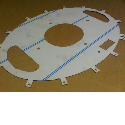

CNC punched motor support discs

These simple motor support discs have been manufactured from 2mm zintec coated mild steel sheet metal. The 3 holes and the outer profile were all CNC punched with existing standard tooling we had on the shelf so again there was no tooling cost for our customer. Each part was CNC punched in under 2 seconds with the last punching operation being the blanking of the outer diameter straight through the die and into a collecting bin. The whole batch of 300 motor support discs were then simply dry barrel de-burred to remove any sharpness on the edges from punching and the components were finished ready for shipping. These parts are a great example of some of the simpler things we manufacture here at V and F Sheet Metal.

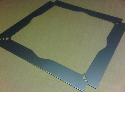

Sheet metal fixing plates

In much the same way that the motor mounting discs above were manufactured by CNC punching and dry barrel de-burring these fixing plates were manufactured by CNC punching with standard tooling. Again, using our Radan sheet metal programming software to create the blank design and select the correct tooling to suit the customer’s design we minimise the number of CNC punch hits and add tags where needed to enable us to hold each part in the sheet of zintec so the operator can remove them carefully ready for de-burring. The batch was several hundred and is a repeat part that we manufacture several times a year.

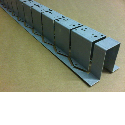

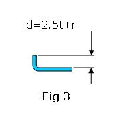

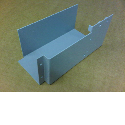

Sheet metal formed sections

These sheet metal formed sections have been manufactured for a customer of ours who assemble fan units for air conditioning systems. These fan support sections have been CNC punched from 0.9mm Zintec coated mild steel, edge de-burred and had the 4 bends formed in one operation with some simple form tooling we made in house to keep the manufactured part cost to a minimum.

So in conclusion were are only a few days into 2016 and already a wide range of manufacturing projects have been finished. Perhaps you have a sheet metal component or assembly you want manufacturing in the UK, please give us a call on 01489 577786 or send us your drawings to sales@vandf.co.uk and we will be happy to take a look and see how we can help you.