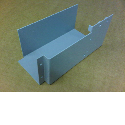

SHEET METAL WORK WITH PRESSED INSERTS

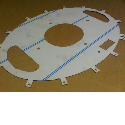

1 February 2016Mild steel chassis with bushes and studs

Great example of sheet metal work with pressed in bushes, studs and stand-offs. All parts are mild steel and zinc plated and will be powder coated on the final finished sheet metal components. These chassis sections are typical of the many designs we manufacture using a range of bushes, studs and stand-offs to make our customers lives a lot easier when it comes to assembling their products. The inserts are very robust and can cope with being degreased and the over temperatures involved with powder coating.

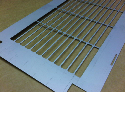

Sheet metal work with hank bushes

A range of Hank bushes inserted in a zintec chassis panel using our Haeger bush inserter machine. Bushes range form M2.5 to M12 in mild steel zinc plated and stainless steel and for a wide range of material sheet thicknesses. As shown here they can be inserted on both sides of the sheet and very close to each other if requited making them a versatile alternative to tapping threads or using separate nuts in assembly. We have inserted millions of hank bushes over the years and still find them to be the best most robust solution to having a captive thread in a sheet metal work.

Mild steel panels with flush head studs

We use flush head studs in a range of sizes, lengths and materials in hundreds of different sheet metal panels. The sheet metal work shown here is typical of the front panels we would make for people with flush head studs. We simple laser cut or CNC punch a hole in the sheet wherever the stud is needed and press the studs in place. If the studs head has to be completely invisible on the front face the a weld stud is used but if a small witness is not important then the pressed in studs are the best solution being cheap to buy, quick to insert and very accurately positioned as they have the hole predefined +/- 0.1mm by laser cutting or CNC punching.

If you have a sheet metal work project that needs bushes, stand offs or studs please give us a call and we will be happy to help. There are also a whole range of more specialist inserts that we can press into to speed up your assembly times and we are happy to discuss your needs and advise where needed.