Standard sheet metal thicknesses and their common manufactured applications

3 April 2024https://www.vandf.co.uk/blog/standard-sheet-metal-thicknesses-and-their-common-applications/

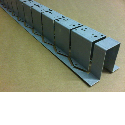

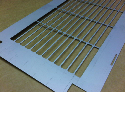

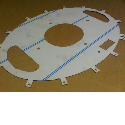

In the lighting industry, the manufacturing of steel sheet metal brackets demands precision and efficiency to meet the rigorous standards of quality and performance. The process typically involves a combination of advanced technologies such as laser cutting, CNC punching, and CNC bending to produce components with exact specifications.

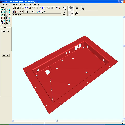

Laser cutting is a pivotal step in the fabrication process, where a high-powered laser beam is used to precisely cut through the 1.2mm thick steel sheets. This technology allows for intricate designs and complex shapes to be achieved with minimal material wastage. By programming the laser cutter with precise measurements, each bracket can be cut with accuracy down to the micron, ensuring consistency across the production line.

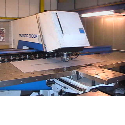

Following laser cutting, CNC punching is employed to create holes, slots, and other features necessary for assembly and attachment. CNC punching machines use computer-controlled movements to precisely punch through the steel sheets, creating uniform holes with high efficiency. This step enables the brackets to be seamlessly integrated into the final lighting fixtures while maintaining structural integrity.

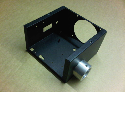

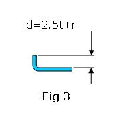

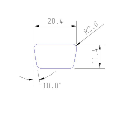

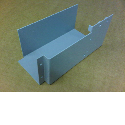

Finally, CNC bending is utilized to shape the flat-cut steel sheets into the desired bracket form. By programming the CNC bending machine with the specific bending angles and dimensions, the steel sheets are accurately bent into shape with minimal distortion or deformation. This process ensures that each bracket conforms to the exact requirements of the design, allowing for easy installation and optimal functionality within the lighting fixtures.

Overall, the integration of laser cutting, CNC punching, and CNC bending technologies enables the efficient and precise manufacturing of 1.2mm thick steel sheet metal brackets for the lighting industry. This advanced approach ensures the production of high-quality components that meet the demands of modern lighting applications.