V and F Sheet Metal Co Ltd

V and F Sheet Metal are a UK Hampshire based sheet metal fabrication, sheet metal work and sub-contract engineering company. We provide sheet metal manufacturing services including CNC punching, CNC laser cutting, CNC bending, welding and press work. Using the latest CAD/CAM software modelling for the best accuracy and speed of sheet metal blank development for our in house CNC punching and CNC laser cutting processes. Supporting a wide range of industries in the UK from electronics to lighting, heating and audio.

Established in Fareham, Hampshire in 1985, with the ability to handle engineering projects from one off small batches of bespoke sheet metal work to high volume power press work V and F Sheet Metal are flexible enough to offer you the complete sub-contract sheet metal fabrication service for your growing company. Regular deliveries to Portsmouth, Southampton, Winchester, Eastleigh, Andover, Basingstoke and other towns in Hampshire from our factory in Fareham is easy. Over-night pallet and small package deliveries right across the UK for those who need it is offered to ease sheet metal component supply.

We have grown to a size where we can offer a complete sub-contract sheet metal fabrication and sheet metal work service to our customers right across the UK. This can include advice on the suitability of sheet metal work designs for manufacturing, sub-assembly work or sub-contract finishing and treatments to your specification e.g. zinc plating, alocrom 1200 / 1000, iridite NCP, surtec 650, silver and black anodising, powder coating, wet painting and screen printing. Continually investing in the latest CNC manufacturing equipment and CAD/CAM software enables us to offer the best combination of quality and price to suit your sub-contract engineering and sheet metal fabrication requirements.

We have a long history of working with UK based lighting companies to reduce their sheet metal fabrication costs and improve the quality of their sub-contract engineering/sheet metal work projects. With many standard CNC punching tools and material set-up costs can be kept to a minimum when considering new sheet metal fabrication projects.

- Sheet Metal Enclosures and sheet metal housings for the electronics industry

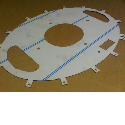

- Reflectors and sheet metal fabrications for the UK lighting industry

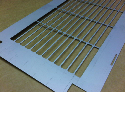

- Sheet Metal Perforated Ventilation and Speaker grilles for the heating and audio industries

- Front panel electronics and rack mount sheet metal work

- Welded assemblies - thin gauge to 6mm sheet metal fabrications in ferrous and non-ferrous materials

- CNC punching using Trumpf CNC punch presses

- CNC laser cutting with our Trumpf 3030 3KW fibre laser cutting machine

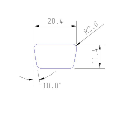

- CAD/CAM processes supported by Radan 3D and 2D software to aid CNC punching and laser cutting

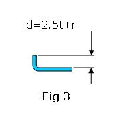

- Sheet Metal CNC bending up to 3.0M long (7 press brakes), including 3 Trumpf 7036 CNC press brakes and a 3M Safan e-Brake CNC press brake

- Tig, Mig, Gas, Spot and Stud sheet metal fabrication welding capacity

- Power press sheet metal work up to 50 tons with custom press tools

Where can I get sheet metal work? Look no further if you are looking for CNC punching, CNC laser cutting, CNC bending and other sheet metal working processes:

For further information and to discuss your personal sheet metal project requirements call us on 01489 577786.

For more information about sheet metal please visit this page What is Sheet Metal Work and how is it made?

Filter products and services

-

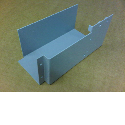

Electronics Enclosures

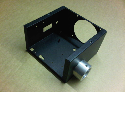

Does your business need Electronics Enclosures? V and F Sheet Metal have been manufacturing Electronics Enclosures since the 1980s. Using the latest CNC punching, laser cutting and CNC bending manufacturing techniques to produce sheet metal Electronics Enclosures. Simple send us your drawings and we will be pleased to supply you with a range of price options to suit your material, treatment and volume requirements.Request a Quote Supplied by V and F Sheet Metal Co Ltd -

Enclosure Cabinets

Does your business use Enclosures Cabinets? V and F Sheet Metal have been manufacturing Enclosure Cabinets since the mid 1980s. Using the latest CNC punching, laser cutting and CNC bending manufacturing techniques to produce sheet metal Enclosure Cabinets. Simple send us your CAD drawings and we will be happy to provide you with a range of price options to suit your material, finish and volume requirements.Request a Quote Supplied by V and F Sheet Metal Co Ltd -

Enclosure Manufacturer

Does your business need the services of an enclosure manufacturer? V and F Sheet Metal have been manufacturing sheet metal enclosure since the 1980s. Using the latest CNC punching, laser cutting and CNC bending manufacturing techniques along with welding processes to produce ferrous and non-ferrous sheet metal enclosures. Simple send us your drawings and we will be happy to provide you with a range of price options to suit your material, gauge, finish and volume requirements.Request a Quote Supplied by V and F Sheet Metal Co Ltd -

Enclosures Bespoke

Does your business need to purchase bespoke enclosures? V and F Sheet Metal have been manufacturing bespoke sheet metal enclosures since the 1980s. Using the latest CNC punching, laser cutting and CNC bending manufacturing techniques along with welding processes to produce bespoke ferrous and non-ferrous sheet metal enclosures. Simple send us your drawings and we will be happy to supply you with a range of price options to suit your material, gauge, finish and volume requirements.Request a Quote Supplied by V and F Sheet Metal Co Ltd -

Enclosures Custom

Does your business need to use custom enclosures? V and F Sheet Metal have been manufacturing custom sheet metal enclosures since the 1980s. Using the latest CNC punching, laser cutting and CNC bending manufacturing techniques along with welding processes to produce bespoke ferrous and non-ferrous sheet metal enclosures. Simple send us your sketches or CAD drawings and we will be happy to supply you with a range of price options to suit your material, gauge, finish and volume requirements.Request a Quote Supplied by V and F Sheet Metal Co Ltd -

Front Panel Sheet Metal

V and F Sheet Metal have been manufacturing Front Panels in sheet metal since the 1980s. Front panels for electrical switch boxes, front panels for 19” rack equipment, front panels for various enclosures. From mild steel, stainless steel and aluminium using CNC punching and laser cutting techniques. To finish off your front panels we can offer you zinc plating, anodising, powder coating and silk screening for the complete front panel package. Send us your designs and we will be happy to quote for your next front panel project.Request a Quote Supplied by V and F Sheet Metal Co Ltd -

Laser Cutting Near Me

V and F Sheet Metal can offer laser cutting of sheet metal work across a wide range of materials. Using a Trumpf fibre laser we are able to laser cut mils steel, aluminium and stainless steel. We can also off laser cutting in copper and brass sheet. Up to 3M x 1.5M and a range of material thicknesses are kept in stock. Ask today for a quote on your next laser cutting sheet metal project.Request a Quote Supplied by V and F Sheet Metal Co Ltd -

Manufacture Engineering

Manufacture engineering using sheet metal, tube, bar and plate from a manufacturing facility in Hampshire UK. If you are looking for a well established sheet metal manufacturing and engineering company based in the UK, try V and F Sheet Metal. For a full list of all the services offered view their website.

Call 01489 577786 or e-mail sales@vandf.co.uk with your specific components requirements.

Request a Quote Supplied by V and F Sheet Metal Co Ltd -

Manufacturing Companies

Components can be manufactured from sheet metal in a wide variety of ways, materials and thicknesses. They can be laser cut, CNC punched of guillotined to start with. Some smaller parts may be sawn or cropped from bar, strip or tube. All these processes are support by V and F Sheet Metal in house with the latest CAD/CAM software. Along with CNC bending and various ferrous and non-ferrous welding techniques. We have been manufacturing sheet components in the UK for over 35 years and have a wide range of tooling and skills in sheet metal manufacturing.Request a Quote Supplied by V and F Sheet Metal Co Ltd -

Manufacturing Sheet Metal

Components can be manufactured from sheet metal in a wide variety of ways, materials and thicknesses. They can be laser cut, CNC punched of guillotined to start with. Some smaller parts may be sawn or cropped from bar, strip or tube. All these processes are support by V and F Sheet Metal in house with the latest CAD/CAM software. Along with CNC bending and various ferrous and non-ferrous welding techniques. We have been manufacturing sheet components in the UK for over 35 years and have a wide range of tooling and skills in sheet metal manufacturing.Request a Quote Supplied by V and F Sheet Metal Co Ltd