RSA Cutting Technologies Ltd

We supply sawing centres for single or multiple cuts, steel or stainless steel parts or non-ferrous metals. Our sawing centres are provided with short set-up times, easy operation, high precision and high economic efficiency. They can be smoothly integrated with all subsequent steps in processes such as deburring, chamfering, measuring, washing and stacking.

Filter products and services

-

RASACUT CC 90

The universal solution for the single cut wiThe newly developed RASACUT CC 90 single cut saw presents the innovative concept of a universal saw family that is optimized for high-volume production with minimal setup time. The robust design and easy operation make the RASACUT CC 90 suitable for various applications. The dynamic gripper feed system achieves high repeatability and increases the output. It can be linked almost wear-free with other saw peripherals at any time. Due to its flexibility, this new saw is suitable for both small batch and mass production. th gripper feed. Do you need a universal multiple cut saw? Then learn about the RASACUT CC 90-2!Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASACUT CC 90-2

As an innovative basic concept of a universal saw family, this double-cut saw is optimized for high-volume production with minimal set-up times. The RASACUT CC 90-2 is robust, easy to operate and suitable for various applications. The dynamic gripper feed system ensures a high output even in the single cut mode for tubes up to 90 mm diameter. The flexible RASACUT CC 90-2 can be easily integrated with other saw peripherals. Do you need a universal single cut saw? Then learn about the RASACUT CC 90!Request a Quote Supplied by RSA Cutting Technologies Ltd -

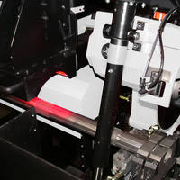

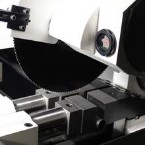

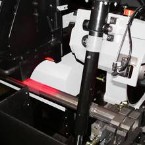

RASACUT MC

Is the performance of our universal single-cut saws inadequate for your needs? You need even greater output? Then our RASACUT MC is exactly the right saw for you! The RASACUT MC is optimally suited for a variety of applications in the automotive, steel trade, furniture and scaffolding industries. Thanks to high output, costs per piece are drastically reduced. Added to this are very high cut quality, rapid change-over for short auxiliary process times as well as linear sawing geometry for the shortest cutting stroke. Thanks to its unbelievably robust construction, the RASACUT MC can be used in a steel works as well as in CNC-sawing and is suitable for three-shift operation. Operator instructions are provided primarily through pictograms and available in nearly all national languages. Control thus demands no CNC-skills from the operator to set the parameters. Do you need a universal single cut saw? Then learn about the RASACUT SC!Request a Quote Supplied by RSA Cutting Technologies Ltd -

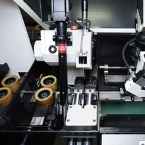

RASACUT MXS

If you need very high output, then select our triple-cut saw RASACUT MXS. The sawing centre is designed for a tube diameter of 8mm to 20mm in triplecut and 6mm to 45mm in single-cut. These dimensions are often found in the automotive industry with special requirements on precision, surface quality and purity. Areas of application include fuel and brake lines or visible components in the interior such as head rest supports. Both the infeed of work pieces as well as transfer to subsequent processes are done using NC-axes that operate with a speed of up to 5m/s. Safe handling of work pieces before, during and after the cutting process guarantees tight tolerances and gentle handling of surfaces so that subsequent chrome plating goes smoothly. Important for automotive suppliers: The work pieces are individually processed and measured after cutting. This guarantees real 100%-control, conforming with the guidelines and standards of the OEMs. Do you need a single cut saw for small diameters? Then learn about the RASACUT XS!Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASACUT OC

Perforated tubes are often used in the automobile industry, especially in the construction of exhausts. And in the manufacture of racking systems, tube with exact spacing between holes are absolutely necessary. In the manufacture of perforated tubes, there are of course deviations in the intervals in punched ranges. High process costs in manual fixed length re-cutting are the result. The RASACUT OC cuts perforated tubes fully automatically and ejects defective perforation intervals in the output material by itself. It reduces the high expenditures for work and material for cutting output lengths of pre-perforated tubes drastically. tubes from a bundle of tubes are automatically separated and transported to the saw with a gripper. This highly precise feed is controlled by an optical system that automatically measures the distances between punched holes and makes sure that the cuts between the punch point and the end of the tube are always within the prescribed tolerances. Sections in the output material in which the punching intervals are impermissibly large relative to each other are removed out and ejected. The result is drastically reduced process costs through increased output on the one hand and discontinuation of 100% control after the fact as well as less reject material. Automatic recognition and positioning of the weld seam is possible as an option.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASACUT SC

RASACUT SC is a universal, highly precise high performance saw for a variety of applications, for example in the automotive, steel trade, furniture and scaffolding industries. RASACUT SC is a single-cut saw with a wide range of diameters that guarantees high output with minimal set-up times. Thanks to its unbelievably robust construction, it can be used in a steel works as well as in CNC-sawing and is suitable for three-shift operation. Operator instructions are provided primarily through pictograms and available in nearly all national languages. Control thus demands no CNC-skills from the operator to set the parameters. Do you need a universal multiple cut saw? Then learn about the RASACUT MC!Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASACUT SH 150

The RASACUT SH 150 is a successful new development of RSA which is unparalleled. The newly designed sawing center allows for extremely fast cutting of tubes and solid bars up to 150 mm diameter. The dynamic 2 or 3 meter gripper feed ensures high outputs. The intelligent, fully automatic feeding of stock lengths - using bundle loader, flat magazine or inclined placing magazine - ensures a smooth flow of materials and reduces cutting time. A RASACUT SH 150 can replace several band saws. Are you looking for a solution for diameters up to 300 mm?Then learn about the RASACUT SH 300!Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASACUT SH 300

As one of the few manufacturers, with our innovative RASACUT SH 300 we offer a high-performance saw for solid and tubular work pieces of large sizes. The newly designed cutting center enables an extremely fast cutting of thin and thick-walled hollow sections and solid bars up to 300 mm diameter and stock lengths up to 14 m. Due to its high dynamic acceleration, the fast and precise gripper feed is able to position 6.5 tons of random material within 6 seconds for 3 m and ensures a high output. The backlash-free saw gearbox and high rated torque allow optimum part and cut surface quality. The intelligent, fully automatic feed-in and feed-out of stock lengths ensures the smooth flow of materials and reduces the cutting time.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASACUT SK

The RASACUT SK saw was developed to separate short work pieces starting from 20 mm length with high precision and output. It is designed for fixed lengths of 20 to 150 mm. The RASACUT SK is a compact short tube saw for small and large series in three shift operation. In contrast to our other models, it is often used to cut bulk material. Areas of application are the manufacture of sleeves and spacer bushes or the manufacture of rubber-metal connectors, e.g. as stabilisers for chassis. With short dimensions, tube handling and smooth, reproducible deburring constitute special challenges. RASACUT SK is a reliable solution that improves work process and quality- not just for sawing, but also for deburring.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASACUT TC

Thin-walled tubes are very critical in the manufacture of fixed lengths. If an unfavourable ratio of diameter to wall thickness is thrown into the mix, a high reject rate is practically guaranteed. For that reason users tend to use laser cutting machines when clean, deformation-free cuts are needed for thin-walled tubes. Admittedly that demands a high investment- but it doesn't need to be that way. Because the RASACUT TC presents a cost effective alternative to laser cutting providing the same quality. This means: Cost savings from the start, without having to compromise on quality. RASACUT TC is a high performance single cut saw for thin-walled tubes starting at 0.4 mm wall thickness, especially for delicate work pieces, such as you find in the automotive, medical technology and aerospace industries or in production of heat exchangers. RASACUT TC is a high performance single cut saw for thin-walled tubes starting at 0.4 mm wall thickness, especially for delicateTo keep from deforming the tube when the saw blade makes contact, the saw uses low forward force at this tricky point. So that this does not detract from total output, the tube is then cut at high speed. When the saw blade then exits, the forward force is slowed again so that burr formation is reduced so much along the edge that the burring can be safely removed with high performance brushes. work pieces, such as you find in the automotive, medical technology and aerospace industries or in production of heat exchangers. The precisely calibrated forward feed is realised using a servo axis. The speeds are calculated independently by the control based on the work piece parameters. Work piece clamping is especially important. Here it is possible to securely clamp even fixed lengths with an unfavourable diameter-to-wall-thickness ratio without deforming the work piece.Request a Quote Supplied by RSA Cutting Technologies Ltd