RSA Cutting Technologies Ltd

We supply sawing centres for single or multiple cuts, steel or stainless steel parts or non-ferrous metals. Our sawing centres are provided with short set-up times, easy operation, high precision and high economic efficiency. They can be smoothly integrated with all subsequent steps in processes such as deburring, chamfering, measuring, washing and stacking.

Filter products and services

-

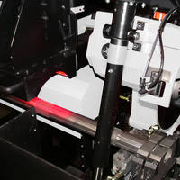

RASACUT XS

RASACUT XS is the alternative to multiple or bundle cut saws in the manufacture of large-scale batches with diameters of 6 to 50 mm. With the single-cut saw RASACUT XS, you improve your quality, reduce unit costs and guarantee high part quality. Areas of application include fuel and brake lines or visible components such as head rest supports. An essential advantage lies fully automatic processing sequence. Through the consistent reduction of cycle times, the RASACUT XS achieves output levels in single cut operation that are just as high as multiple or bundle-cut saws, depending on the dimension range, even higher! Do you need a multiple cut saw for small diameters? Then learn about the RASACUT MXS!Request a Quote Supplied by RSA Cutting Technologies Ltd -

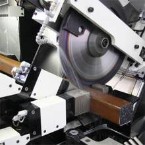

RASACUT XXL

The sawing centre RASACUT XXL was developed especially for cutting tubes and solid bars up to 170 mm. With that you achieve a reduction in sawing time by up to 90% compared to modern bandsaws along with improved quality of cut surface in terms of both squareness and surface roughness. The single-cut saw guarantees high output with optimal part and cut surface quality as well as precisely weighted cuts with 100 percent control optional. RASACUT XXL is optimally suited for use in the automotive, forging and steel trade industries.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASA DUO

The RASA DUO one-ups the RASA MONO in universality. Its two machining stations makes it the right equipment wherever deburring jobs are constantly changing. By combining high performance brushes for deburring on the first and, using the example of an abrasive block, on the second drive station centre waste or an oxide layer can be ground off and the workpiece then deburred without any lost time. RASA DUO guarantees reliable deburring of front faces and long sides on tubes, hollow profiles, solid material profiles and sheets of steel, stainless steel and non-ferrous metals. Guaranteed evenly deburred workpieces for the entire life of the deburring tool. The clearance between the high performance brush and workpieces rest is variable and compensates for brush wear. RASA DUO is suitable for tubes and profiles with diameters of up to 90 mm and lengths of 100 mm and up. The optional short tube deburring attachment KRV for workpieces shorter than 100 mm. Templates for round tubes, square tubes and other shaped profiles can quickly be changed. Changing brushes takes less than a minute. The deburring process doesn't depend on the workpiece shape: manually turning the workpiece by 360° will simultaneously deburr the inner and outer edges of hollow profiles without producing secondary burs or altering the size.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASA DUO deburring machine

The RASA DUO one-ups the RASA MONO in universality. Its two machining stations makes it the right equipment wherever deburring jobs are constantly changing. By combining high performance brushes for deburring on the first and, using the example of an abrasive block, on the second drive station centre waste or an oxide layer can be ground off and the workpiece then deburred without any lost time. RASA DUO guarantees reliable deburring of front faces and long sides on tubes, hollow profiles, solid material profiles and sheets of steel, stainless steel and non-ferrous metals. Guaranteed evenly deburred workpieces for the entire life of the deburring tool. The clearance between the high performance brush and workpieces rest is variable and compensates for brush wear. RASA DUO is suitable for tubes and profiles with diameters of up to 90 mm and lengths of 100 mm and up. The optional short tube deburring attachment KRV for workpieces shorter than 100 mm. Templates for round tubes, square tubes and other shaped profiles can quickly be changed. Changing brushes takes less than a minute. The deburring process doesn't depend on the workpiece shape: manually turning the workpiece by 360° will simultaneously deburr the inner and outer edges of hollow profiles without producing secondary burs or altering the size.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASAMAT

Our RASAMAT products are ideal for single pieces and small batches. After just a short training period they are easy to operate, even by less skilled personnel. The RASAMAT 2002 will handle asymmetrical profile shapes or short workpieces. Here the workpiece is fed through an aperture cover which can also be changed over within seconds. Both modules combine maximum workplace safety with flexibility and ultra short set-up times. Depending on the size of the workpiece deburring takes only one to five seconds per endface. Even with small daily volumes the RASAMAT will cover its investment in less than twelve months.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASAMAT Automat

The RASAMAT Automat deburrs both workpiece faces simultaneously. A conveyor feeds the workpiece. The RASAMAT Automat is a feed-through system with top output volumes of 1,800 pieces per hour. workpiece sizes can be switched within seconds, also automated - analogue the parameters entered on the control console or using the workpieces data copied from another machine, for example a saw. No additional set-up required. Amortisation times of six months aren't uncommon with the RASAMAT Automat. Investment costs are manageable, engineering costs for integrating it into the existing production low, and the increase in production three times that of a semi-automated solution. The RASAMAT Automat is usually linked with an upstream separation system. Additional machining modules can be connected after deburring, for example workpiece length measurement or online cleaning.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASAMAT automat extrusion deburring

The RASAMAT Automat deburrs both workpiece faces simultaneously. A conveyor feeds the workpiece. The RASAMAT Automat is a feed-through system with top output volumes of 1,800 pieces per hour. workpiece sizes can be switched within seconds, also automated - analogue the parameters entered on the control console or using the workpieces data copied from another machine, for example a saw. No additional set-up required. Amortisation times of six months aren't uncommon with the RASAMAT Automat. Investment costs are manageable, engineering costs for integrating it into the existing production low, and the increase in production three times that of a semi-automated solution. The RASAMAT Automat is usually linked with an upstream separation system. Additional machining modules can be connected after deburring, for example workpiece length measurement or online cleaning.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASAMAT profile shaping

Our RASAMAT products are ideal for single pieces and small batches. After just a short training period they are easy to operate, even by less skilled personnel. The RASAMAT 2002 will handle asymmetrical profile shapes or short workpieces. Here the workpiece is fed through an aperture cover which can also be changed over within seconds. Both modules combine maximum workplace safety with flexibility and ultra short set-up times. Depending on the size of the workpiece deburring takes only one to five seconds per endface. Even with small daily volumes the RASAMAT will cover its investment in less than twelve months. Specialists in the deburring of difficult workpieces The RASAMAT system can even be adapted for the deburring of awkward and heavy workpieces. On a transverse feeding table the workpiece is pneumatically clamped. After the deburring process is started by two-handed release buttons, the table moves the profile along the rotating RASAMAT head. Depending on the cross section, all edges are evenly rounded off in between four to twelve seconds.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASAMAX DUO

RASAMAX DUO was developed specifically for quickly and reliably deburring straight sheets. The deburring machine features two counter-rotating deburring brushes on two offset levels. Using this concept the top and lower edge of the sheet are deburred simultaneously in just one cycle. That means up to 50 % time savings compared to other methods! The workpiece is simply placed on the roller table and guided along the lay-on edge and the high performance brushes. Razor-sharp sheet edges - e.g. caused by shearing - are safely rounded off within seconds. Yet it causes no secondary burrs or alter the size. The use of plastic bonded high performance brushes allows straight sheet edges to be deburred without damaging the surface. RASAMAX DUO is suitable for deburring single pieces and small batches, and the robust construction is designed for continuous operation.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASAMAX DUO deburring straight sheets

RASAMAX DUO was developed specifically for quickly and reliably deburring straight sheets. The deburring machine features two counter-rotating deburring brushes on two offset levels. Using this concept the top and lower edge of the sheet are deburred simultaneously in just one cycle. That means up to 50 % time savings compared to other methods! The workpiece is simply placed on the roller table and guided along the lay-on edge and the high performance brushes. Razor-sharp sheet edges - e.g. caused by shearing - are safely rounded off within seconds. Yet it causes no secondary burrs or alter the size. The use of plastic bonded high performance brushes allows straight sheet edges to be deburred without damaging the surface. RASAMAX DUO is suitable for deburring single pieces and small batches, and the robust construction is designed for continuous operation.Request a Quote Supplied by RSA Cutting Technologies Ltd